Caterpillar Cat CB-534D VIBRATORY COMPACTOR (Prefix B5M) Service Repair Manual Instant Download

Please open the website below to get the complete manualnn//

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

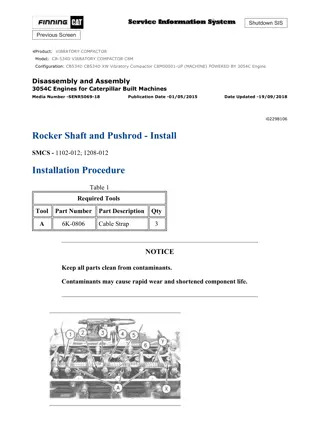

CB534D CB534D XW Vibratory Compactor B5M00001-UP (MACHINE) POWERE... 1/3 Product: VIBRATORY COMPACTOR Model: CB-534D VIBRATORY COMPACTOR B5M Configuration: CB534D CB534D XW Vibratory Compactor B5M00001-UP (MACHINE) POWERED BY 3054C Engine Disassembly and Assembly 3054C Engines for Caterpillar Built Machines Media Number -SENR5069-18 Publication Date -01/05/2015 Date Updated -19/09/2018 i02293102 Engine Oil Pump - Install - Engines Without a Balancer SMCS - 1304-012 Installation Procedure Note: This procedure is for the installation of the engine oil pump on engines that are not equipped with a balancer. Refer to this Disassembly and Assembly Manual, "Balancer Group - Install" for information on the installation of the engine oil pump on engines that are equipped with a balancer. NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. NOTICE If any of the parts on the engine oil pump are worn or damaged, the entire pump must be replaced. 1. Clean all of the internal components of the oil pump if the front cover of the oil pump was previously removed in order to inspect the internal components. Check the internal components for wear and for other damage. Check the clearance between the outer rotor of the oil pump and the oil pump body. Check the clearance between the outer rotor and the inner rotor. Check the end play movement of the rotor. Refer to the Systems Operation/Testing and Adjusting Manual, "Engine Oil Pump - Inspect". Replace the engine oil pump if any of the components are worn or damaged. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/5/7

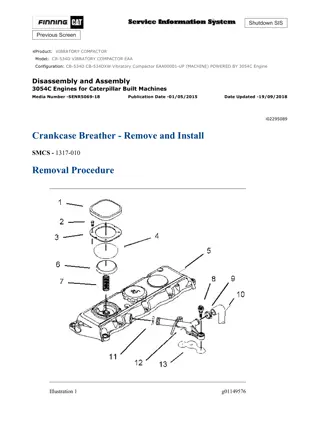

CB534D CB534D XW Vibratory Compactor B5M00001-UP (MACHINE) POWERE... 2/3 2. Lubricate the inner rotor and the outer rotor of the engine oil pump with clean engine lubricating oil. Install the front cover of the engine oil pump onto the body of the oil pump. Install the setscrews and tighten the setscrews in order to secure the front cover to the body. Illustration 1 g00956778 3. Install the engine oil pump (9) into the assembly of the engine oil pump (2). Install the setscrews (8). Tighten the setscrews to a torque of 9 N m (80 lb in). 4. Fill engine oil pump (9) with clean engine oil. 5. Position the assembly of the engine oil pump (2) against the cylinder block. Ensure that dowel pin (10) and hollow dowel (11) are correctly located in the cylinder block. 6. Install the setscrews (1). Tighten the setscrews to a torque of 44 N m (32 lb ft). 7. Check the backlash between the idler gear of the oil pump and the crankshaft gear. Refer to the Specifications Manual, "Gear Group - Front" for further information. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/5/7

CB534D CB534D XW Vibratory Compactor B5M00001-UP (MACHINE) POWERE... 3/3 Illustration 2 g01147909 Improper assembly of parts that are spring loaded can cause bodily injury. To prevent possible injury, follow the established assembly procedure and wear protective equipment. 8. If the pressure relief valve (5) was removed, install the pressure relief valve. Refer to this Disassembly and Assembly Manual, "Engine Oil Relief Valve - Remove and Install" for further information. 9. Position the suction pipe (4) and install the setscrews (3). End By: a. Install the oil pan. Refer to Disassembly and Assembly, "Engine Oil Pan - Remove and Install". https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/5/7

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

CB534D CB534D XW Vibratory Compactor B5M00001-UP (MACHINE) POWERE... 1/4 Product: VIBRATORY COMPACTOR Model: CB-534D VIBRATORY COMPACTOR B5M Configuration: CB534D CB534D XW Vibratory Compactor B5M00001-UP (MACHINE) POWERED BY 3054C Engine Disassembly and Assembly 3054C Engines for Caterpillar Built Machines Media Number -SENR5069-18 Publication Date -01/05/2015 Date Updated -19/09/2018 i02293115 Water Pump - Remove and Install SMCS - 1361-011; 1361-012 Removal Procedure Start By: a. Remove the fan. Refer to Disassembly and Assembly, "Fan - Remove and Install". NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. NOTICE Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting, and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids. Refer to Special Publication, NENG2500, "Dealer Service Tool Catalog" for tools and supplies suitable to collect and contain fluids on Cat products. Dispose of all fluids according to local regulations and mandates. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/5/7

CB534D CB534D XW Vibratory Compactor B5M00001-UP (MACHINE) POWERE... 2/4 1. Drain the coolant from the cooling system into a suitable container for storage or disposal. Note: Refer to Operation and Maintenance Manual, "Refill Capacities" for the coolant capacity of the engine. 2. Loosen the clamps and remove the hose from the water pump inlet. Illustration 1 g00952695 3. Remove the setscrews (3) that fasten the water pump (4) to the front housing (1). 4. If necessary, tap the water pump with a soft hammer in order to loosen the water pump. 5. Remove water pump (4). Remove the gasket (2) from the front housing and the water pump. Discard the gasket (2). Installation Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 9S-3263 Thread Lock - Guide Bolt (M8 X 1.25 by 70 mm) B - 2 NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/5/7

CB534D CB534D XW Vibratory Compactor B5M00001-UP (MACHINE) POWERE... 3/4 1. Inspect the drive gear for the water pump for wear or other damage. If necessary, replace the drive gear. 2. Clean the joint faces of the water pump and the front housing. Note: Do not use sealant on the gasket for the water pump. Illustration 2 g00952716 3. Install Tooling (B) in the front housing (1). 4. Install a new gasket (2) on the front housing. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/5/7

CB534D CB534D XW Vibratory Compactor B5M00001-UP (MACHINE) POWERE... 4/4 Illustration 3 g00952731 5. Install the water pump (4) on the front housing. Note: New setscrews have sealant on the first 13 mm (0.5 inch) of the threads. In order to reuse the old setscrews, clean the old sealant from the setscrews and apply Tooling (A) to the setscrews. 6. Install the setscrews (3) that fasten the water pump to the front housing. Do not tighten the setscrews at this time. 7. Remove Tooling (B) and install the remaining setscrews in order to secure the water pump to the front housing. Note: Tighten the setscrews evenly in order to pull the water pump into the front housing. 8. Tighten the setscrews (3) to a torque of 22 N m (16 lb ft). Tighten the setscrews in the sequence that is shown in Illustration 3. 9. Install the hose to the water pump inlet. Tighten the hose clamps. 10. Fill the cooling system with coolant. Refer to Operation and Maintenance, "Refill Capacities" for the cooling system capacity. End By: a. Install the fan. Refer to Disassembly and Assembly, "Fan - Remove and Install". https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/5/7

CB534D CB534D XW Vibratory Compactor B5M00001-UP (MACHINE) POWERE... 1/3 Product: VIBRATORY COMPACTOR Model: CB-534D VIBRATORY COMPACTOR B5M Configuration: CB534D CB534D XW Vibratory Compactor B5M00001-UP (MACHINE) POWERED BY 3054C Engine Disassembly and Assembly 3054C Engines for Caterpillar Built Machines Media Number -SENR5069-18 Publication Date -01/05/2015 Date Updated -19/09/2018 i02293128 Water Temperature Regulator - Remove and Install SMCS - 1355-010 Removal Procedure NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. NOTICE Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting, and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids. Refer to Special Publication, NENG2500, "Dealer Service Tool Catalog" for tools and supplies suitable to collect and contain fluids on Cat products. Dispose of all fluids according to local regulations and mandates. 1. Drain the coolant from the cooling system to a level below the water temperature regulator into a suitable container for storage or disposal. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/5/7

CB534D CB534D XW Vibratory Compactor B5M00001-UP (MACHINE) POWERE... 2/3 2. Loosen the hose clamp from the upper radiator hose and remove the upper radiator hose from the water temperature regulator housing. Illustration 1 g00953937 3. Remove the setscrews (2) that hold the water temperature regulator housing (1) in position on the cylinder head. Remove the water temperature regulator housing. Remove the O-ring seal from the water temperature regulator housing. Discard the O-ring. 4. Squeeze the retainers (A) and rotate the water temperature regulator in order to release the water temperature regulator from the tabs of the water temperature regulator housing. 5. Refer to Systems Operation, Testing and Adjusting, "Water Temperature Regulator - Test" for the correct procedure on testing the water temperature regulator. Installation Procedure NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. 1. Clean the water temperature regulator housing. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/5/7

CB534D CB534D XW Vibratory Compactor B5M00001-UP (MACHINE) POWERE... 3/3 Illustration 2 g00953937 2. Position the water temperature regulator (3) in the water temperature regulator housing. Squeeze the retainers (A) and rotate the water temperature regulator in order to secure the water temperature regulator to the water temperature regulator housing. Note: The retainers (A) must be inserted behind the tabs of the water temperature regulator housing in order to secure the water temperature regulator during engine operation. 3. Install a new O-ring seal on the water temperature regulator housing (1). Lubricate the O- ring seal with red rubber grease. Position the water temperature regulator housing on the cylinder head. 4. Install the setscrews (2) that fasten water temperature regulator housing (1) to the cylinder head. 5. Install the upper radiator hose and tighten the hose clamps. Refer to the Torque Specifications Manual for the correct torque. 6. Fill the cooling system to the proper level. Refer to the Operation and Maintenance Manual, "Refill Capacities" for further information. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/5/7

CB534D CB534D XW Vibratory Compactor B5M00001-UP (MACHINE) POWERE... 1/3 Product: VIBRATORY COMPACTOR Model: CB-534D VIBRATORY COMPACTOR B5M Configuration: CB534D CB534D XW Vibratory Compactor B5M00001-UP (MACHINE) POWERED BY 3054C Engine Disassembly and Assembly 3054C Engines for Caterpillar Built Machines Media Number -SENR5069-18 Publication Date -01/05/2015 Date Updated -19/09/2018 i02293555 Flywheel - Remove SMCS - 1156-011 Removal Procedure Table 1 Required Tools Tool Part Number Part Description Qty A - Guide Bolt (1/2 inch - 20 NF by 4 inch) 2 B 138-7575 Link Bracket 1 NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/5/7

CB534D CB534D XW Vibratory Compactor B5M00001-UP (MACHINE) POWERE... 2/3 Illustration 1 g01148312 Typical example 1. Remove the two setscrews and install the Tooling (A) as guides. Note: The weight of the flywheel (2) is approximately 54 kg (119 lb). Install the Tooling (B) in order to support the flywheel (2) before the remainder of the setscrews (1) are removed. 2. Remove the remaining setscrews (1) that secure flywheel (2) to the crankshaft. 3. Remove the flywheel (2) from the engine. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/5/7

CB534D CB534D XW Vibratory Compactor B5M00001-UP (MACHINE) POWERE... 3/3 Illustration 2 g01148313 4. Check the condition of the ring gear (4). Remove the ring gear (4) if the ring gear is worn or damaged. Note: Identify the orientation of the ring gear (4) on the flywheel (2) and the position of the chamfer on the teeth for the correct positioning when the new ring gear is installed. 5. Place the flywheel (2) and the ring gear (4) on a suitable support. Use a hammer and a chisel in order to remove the ring gear (4) from the flywheel (2). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/5/7

CB534D CB534D XW Vibratory Compactor B5M00001-UP (MACHINE) POWERE... 1/3 Product: VIBRATORY COMPACTOR Model: CB-534D VIBRATORY COMPACTOR B5M Configuration: CB534D CB534D XW Vibratory Compactor B5M00001-UP (MACHINE) POWERED BY 3054C Engine Disassembly and Assembly 3054C Engines for Caterpillar Built Machines Media Number -SENR5069-18 Publication Date -01/05/2015 Date Updated -19/09/2018 i07030444 Flywheel - Install SMCS - 1156-012 Installation Procedure Table 1 Required Tools Tool Part Number Part Description Qty Guide Bolt (1/2 inch - 20 NF by 4 inch) A - 2 B 138-7575 Link Bracket 1 NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. 1. Thoroughly clean the flywheel housing. Inspect the crankshaft rear seal for leaks. If there are any oil leaks, refer to this Disassembly and Assembly Manual, "Crankshaft Rear Seal - Remove" for the correct procedure. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/5/7

CB534D CB534D XW Vibratory Compactor B5M00001-UP (MACHINE) POWERE... 2/3 Illustration 1 g00909349 Always wear protective gloves when handling parts that have been heated. Note: If ring gear (3) has been removed from flywheel (2). Identify the orientation of ring gear (3) on the flywheel for the correct positioning when the new ring gear is installed. 2. Heat the ring gear to 250 C (480 F) in an oven to install the ring gear onto the flywheel. Ensure that the orientation of the ring gear is correct and quickly install the ring gear onto the flywheel. Note: Do not use a torch to heat the ring gear. 3. Clean flywheel (2) and ring gear (3) when the ring gear has cooled. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/5/7

CB534D CB534D XW Vibratory Compactor B5M00001-UP (MACHINE) POWERE... 3/3 Illustration 2 g01148312 4. Install the Tooling (A) on the crankshaft. Install the Tooling (B) and a suitable lifting device on flywheel (2) and position the flywheel in the flywheel housing. The weight of the flywheel is approximately 54 kg (119 lb). 5. Install bolts (1) to flywheel (2). 6. Remove Tooling (A). Install the remaining bolts (1) that secure flywheel (2) to the crankshaft. Tighten the bolts (1) to a torque of 140 N m (103 lb ft). 7. Check the alignment of flywheel (2) with the crankshaft. Refer to Testing and Adjusting, "Flywheel - Inspect" for the correct procedure. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/5/7

CB534D CB534D XW Vibratory Compactor B5M00001-UP (MACHINE) POWERE... 1/2 Product: VIBRATORY COMPACTOR Model: CB-534D VIBRATORY COMPACTOR B5M Configuration: CB534D CB534D XW Vibratory Compactor B5M00001-UP (MACHINE) POWERED BY 3054C Engine Disassembly and Assembly 3054C Engines for Caterpillar Built Machines Media Number -SENR5069-18 Publication Date -01/05/2015 Date Updated -19/09/2018 i02293665 Crankshaft Rear Seal - Remove SMCS - 1161-011 Removal Procedure Start By: a. Remove the flywheel. Refer to Disassembly and Assembly, "Flywheel - Remove". NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. NOTICE Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting, and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids. Refer to Special Publication, NENG2500, "Dealer Service Tool Catalog" for tools and supplies suitable to collect and contain fluids on Cat products. Dispose of all fluids according to local regulations and mandates. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/5/7

CB534D CB534D XW Vibratory Compactor B5M00001-UP (MACHINE) POWERE... 2/2 Illustration 1 g00991388 Note: The crankshaft rear seal is nonserviceable. If the crankshaft rear seal is removed, the complete housing assembly must be replaced. 1. Remove the setscrews (1) from the housing assembly (2). 2. Remove the housing assembly (2) from the cylinder block. Discard the housing assembly (2). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/5/7

CB534D CB534D XW Vibratory Compactor B5M00001-UP (MACHINE) POWERE... 1/4 Product: VIBRATORY COMPACTOR Model: CB-534D VIBRATORY COMPACTOR B5M Configuration: CB534D CB534D XW Vibratory Compactor B5M00001-UP (MACHINE) POWERED BY 3054C Engine Disassembly and Assembly 3054C Engines for Caterpillar Built Machines Media Number -SENR5069-18 Publication Date -01/05/2015 Date Updated -19/09/2018 i02293676 Crankshaft Rear Seal - Install SMCS - 1161-012 Installation Procedure Table 1 Required Tools Tool Part Number Part Description Qty A FT-2806 Alignment Tool 1 Note: The crankshaft rear seal and the housing for the crankshaft rear seal are manufactured as a one-piece assembly. The assembly of the crankshaft rear seal uses ten setscrews in order to fasten the assembly to the cylinder block. Note: The following procedure assumes that the crankshaft rear seal is a replacement assembly. Note: The crankshaft rear seal is lubricated. There is no need to lubricate the seal or the crankshaft flange before installation. Note: An installation sleeve (2) is supplied with the new housing assembly. The installation sleeve must be in place when housing assembly is installed on the crankshaft flange in order to prevent damage to the crankshaft rear seal during assembly. NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/5/7

CB534D CB534D XW Vibratory Compactor B5M00001-UP (MACHINE) POWERE... 2/4 1. Ensure that the crankshaft flange (1) is clean, dry and free from rough metal edges. Ensure that the face of the cylinder block and the bridge in the crankcase are clean and dry. Illustration 1 g01148393 2. Remove the packaging from the new assembly of the crankshaft rear seal (3). Ensure that the plastic sleeve (2) is squarely installed within the seal of the assembly of the crankshaft rear seal (3). The plastic sleeve (2) is included in order to protect the lip of the seal as the lip is pushed over the crankshaft flange (1). Illustration 2 g01004958 Typical example 3. Place the assembly of the crankshaft rear seal (3) over the crankshaft flange (1) and engage the plastic sleeve (2) onto the crankshaft flange. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/5/7

CB534D CB534D XW Vibratory Compactor B5M00001-UP (MACHINE) POWERE... 3/4 4. Ensure that the plastic sleeve (2) is engaged onto the crankshaft flange (1). Push the assembly of the crankshaft rear seal (3) evenly and push the assembly smoothly onto the crankshaft flange (1) until the assembly is against the cylinder block. During this process, the plastic sleeve (2) will be forced out of the assembly of the crankshaft rear seal (3). Discard the plastic sleeve (2). 5. Rotate the assembly of the crankshaft rear seal (3) in order to align the setscrew holes in the assembly with the setscrew holes in the rear face of the cylinder block. 6. Install the setscrews (5) in order to position housing assembly (3) to the cylinder block. Do Not tighten the bolts. 7. Place the Tooling (A) over housing assembly (2). This will center the housing assembly onto the crankshaft flange (3). Illustration 3 g01148495 8. Tighten the setscrews (1) in numerical order to a torque of 22 N m (16 lb ft). Do not tighten the setscrews (X) at this time. 9. Remove the Tooling (A). Tighten the setscrews (X) to a torque of 22 N m (16 lb ft). End By: a. Install the flywheel. Refer to Disassembly and Assembly, "Flywheel - Install". https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/5/7

CB534D CB534D XW Vibratory Compactor B5M00001-UP (MACHINE) POWERE... 1/2 Product: VIBRATORY COMPACTOR Model: CB-534D VIBRATORY COMPACTOR B5M Configuration: CB534D CB534D XW Vibratory Compactor B5M00001-UP (MACHINE) POWERED BY 3054C Engine Disassembly and Assembly 3054C Engines for Caterpillar Built Machines Media Number -SENR5069-18 Publication Date -01/05/2015 Date Updated -19/09/2018 i05322247 Crankshaft Wear Sleeve (Rear) - Remove SMCS - 1161-011-ZV Removal Procedure Table 1 Required Tools Tool Part Number Part Description Qty 242-9955 Puller 1 A - Spacer 1 Start By: A. Remove the crankshaft rear seal. Refer to Disassembly and Assembly, "Crankshaft Rear Seal - Remove and Install" for the correct procedure. NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. Note: Wear sleeves are used to reclaim worn seal surfaces or damaged seal surfaces. Wear sleeves are not original equipment. The wear sleeve is supplied with a crankshaft rear seal that has a larger internal diameter than a standard crankshaft rear seal. A standard crankshaft rear seal cannot be used if a wear sleeve is installed. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/5/7

CB534D CB534D XW Vibratory Compactor B5M00001-UP (MACHINE) POWERE... 2/2 Illustration 1 g02815577 Typical example 1. Use Tooling (A) in order to remove crankshaft wear sleeve (1) from crankshaft (2) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/5/7

CB534D CB534D XW Vibratory Compactor B5M00001-UP (MACHINE) POWERE... 1/2 Product: VIBRATORY COMPACTOR Model: CB-534D VIBRATORY COMPACTOR B5M Configuration: CB534D CB534D XW Vibratory Compactor B5M00001-UP (MACHINE) POWERED BY 3054C Engine Disassembly and Assembly 3054C Engines for Caterpillar Built Machines Media Number -SENR5069-18 Publication Date -01/05/2015 Date Updated -19/09/2018 i05764187 Crankshaft Wear Sleeve (Rear) - Install SMCS - 1161-012-ZV Installation Procedure Table 1 Required Tools Tool Part Number Part Description Qty 438-3244 Oil Seal Installer 1 A 8T-0375 Bolt 1 5P-8247 Hard Washer 1 438-3245 Oil Seal Locator 1 B 9U-6172 Bolt 2 NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. Note: Wear sleeves are used to reclaim worn seal surfaces or damaged seal surfaces. Wear sleeves are not original equipment. The wear sleeve is supplied with a crankshaft rear seal that has a larger internal diameter than a standard crankshaft rear seal. A standard crankshaft rear seal cannot be used if a wear sleeve is installed. 1. Ensure that the crankshaft is thoroughly clean and dry. Remove any areas of raised damage. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/5/7

CB534D CB534D XW Vibratory Compactor B5M00001-UP (MACHINE) POWERE... 2/2 2. Lubricate the inner surface of the crankshaft wear sleeve with clean engine oil. Illustration 1 g03657723 Sectional view of the crankshaft, the wear sleeve, and the installation tool 3. Use Tooling (A) and Tooling (B) to install the crankshaft wear sleeve, as follows: a. Align Tooling (B) with the dowels in crankshaft (2) and install Tooling (B) to the crankshaft. Ensure the correct orientation. Note: Verify that Tooling (A) will slide freely over Tooling (B). b. Carefully slide crankshaft wear sleeve (1) over Tooling (B) until the crankshaft wear sleeve contacts the rear of crankshaft (2). c. Assemble Tooling (A) to Tooling (B) and install the bolt and the washer. Ensure that the face of Tooling (A) with the deep counterbore is toward crankshaft wear sleeve (1). d. Tighten the bolt until Tooling (A) bottoms out on Tooling (B) in order to pull crankshaft wear sleeve (1) onto crankshaft (2). e. Remove Tooling (A) and Tooling (B). End By: a. Install the new crankshaft rear seal that was supplied with the crankshaft wear sleeve. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/5/7

CB534D CB534D XW Vibratory Compactor B5M00001-UP (MACHINE) POWERE... 1/4 Product: VIBRATORY COMPACTOR Model: CB-534D VIBRATORY COMPACTOR B5M Configuration: CB534D CB534D XW Vibratory Compactor B5M00001-UP (MACHINE) POWERED BY 3054C Engine Disassembly and Assembly 3054C Engines for Caterpillar Built Machines Media Number -SENR5069-18 Publication Date -01/05/2015 Date Updated -19/09/2018 i02294250 Flywheel Housing - Remove and Install SMCS - 1157-010 Removal Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 138-7575 Link Bracket 2 Start By: a. Remove the electric starting motor. Refer to Disassembly and Assembly, "Electric Starting Motor - Remove and Install". b. Remove the flywheel. Refer to Disassembly and Assembly, "Flywheel - Remove". NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. NOTICE Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting, and repair of the product. Be prepared to collect the fluid with suitable containers https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/5/7

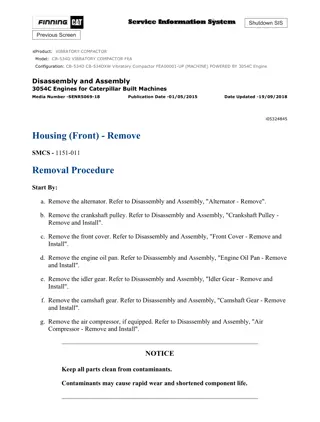

CB534D CB534D XW Vibratory Compactor B5M00001-UP (MACHINE) POWERE... 2/4 before opening any compartment or disassembling any component containing fluids. Refer to Special Publication, NENG2500, "Dealer Service Tool Catalog" for tools and supplies suitable to collect and contain fluids on Cat products. Dispose of all fluids according to local regulations and mandates. 1. The weight of the flywheel housing (3) is approximately 39 kg (85 lb). Use suitable lifting equipment to support the flywheel housing (3) while the setscrews (1) are being removed and while the flywheel housing is being removed. Illustration 1 g00977367 2. Remove the setscrews (1) from the top of the flywheel housing (3). 3. Attach the Tooling (A) and a suitable lifting device to the flywheel housing (3). 4. Remove the setscrews (2) that attach the flywheel housing (3) to the cylinder block. 5. Remove the flywheel housing (3). If necessary, tap the flywheel housing with a soft faced hammer in order to separate the flywheel housing from the cylinder block. Installation Procedure Table 2 Required Tools Tool Part Number Part Description Qty A 138-7575 Link Bracket 2 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/5/7

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

CB534D CB534D XW Vibratory Compactor B5M00001-UP (MACHINE) POWERE... 3/4 NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. 1. Clean the rear face of the cylinder block and the mating surface of the flywheel housing (3). Illustration 2 g00977388 2. If a felt seal (5) is installed, replace the felt seal. Inspect the dowels (4) in the cylinder block that align the flywheel housing (3). Replace the dowels, if necessary. 3. The weight of the flywheel housing (3) is approximately 39 kg (85 lb). Use the Tooling (A) and a suitable lifting device to position the flywheel housing (3) on the dowels (4) that are on the cylinder block. 4. Install the setscrews (1) that attach the flywheel housing (3) to the cylinder block. 5. Install the setscrews (2) that attach the flywheel housing (3) to the cylinder block. Tighten the setscrews (1) and the setscrews (2) to the following torque: M10 "8.8" ... 44 N m (33 lb ft) M10 "10.9" ... 63 N m (46 lb ft) M12 "8.8" ... 75 N m (55 lb ft) M12 "10.9" ... 115 N m (85 lb ft) 6. Remove Tooling (A) and the lifting device from the flywheel housing. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/5/7

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com