Caterpillar Cat CB-334E and CB-335E Vibratory Compactor (Prefix C3F) Service Repair Manual Instant Download

Please open the website below to get the complete manualnn//

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

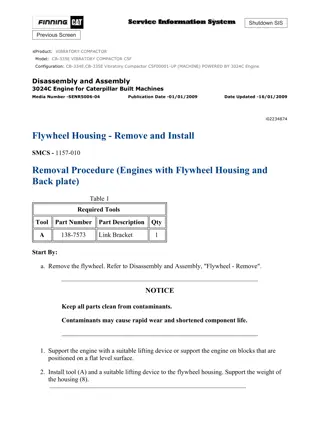

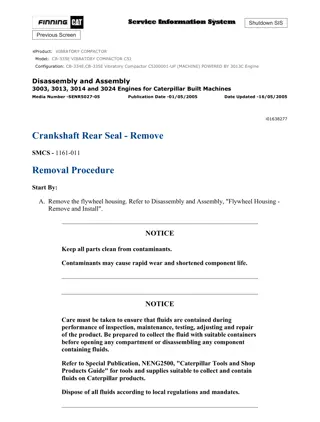

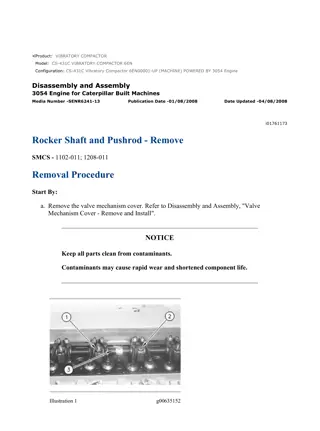

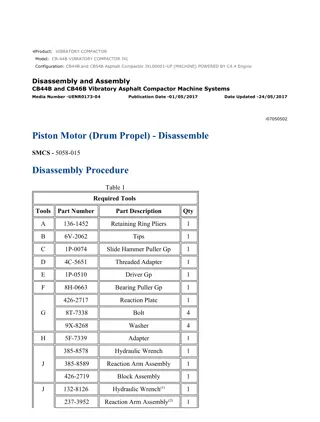

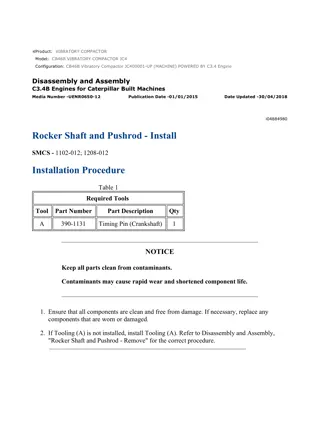

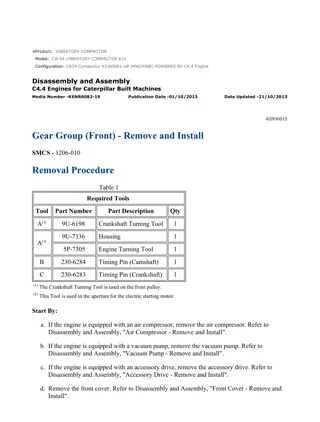

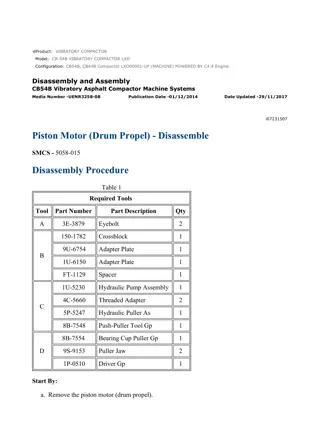

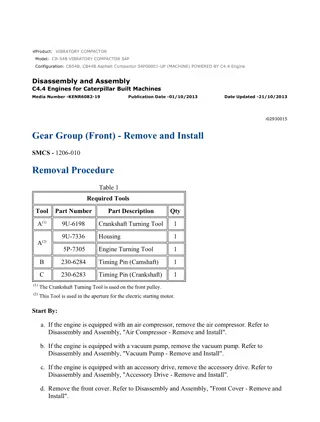

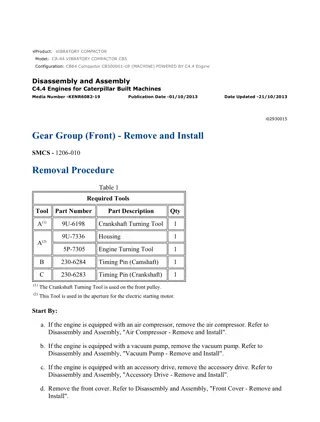

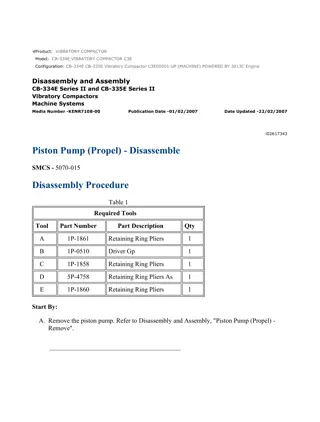

CB-334E CB-335E Vibratory Compactor C3F00001-UP (MACHINE) POWERED B... 1/15 Shutdown SIS Previous Screen Product: VIBRATORY COMPACTOR Model: CB-335E VIBRATORY COMPACTOR C3F Configuration: CB-334E CB-335E Vibratory Compactor C3F00001-UP (MACHINE) POWERED BY 3013C Engine Disassembly and Assembly CB-334E Series II and CB-335E Series II Vibratory Compactors Machine Systems Media Number -KENR7108-00 Publication Date -01/02/2007 Date Updated -22/02/2007 i02617401 Piston Pump (Propel) - Assemble SMCS - 5070-016 Assembly Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 1P-1861 Retaining Ring Pliers 1 B 1P-0510 Driver Gp 1 C 1P-1858 Retaining Ring Pliers 1 D 5P-4758 Retaining Ring Pliers As 1 E 1P-1860 Retaining Ring Pliers 1 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/16

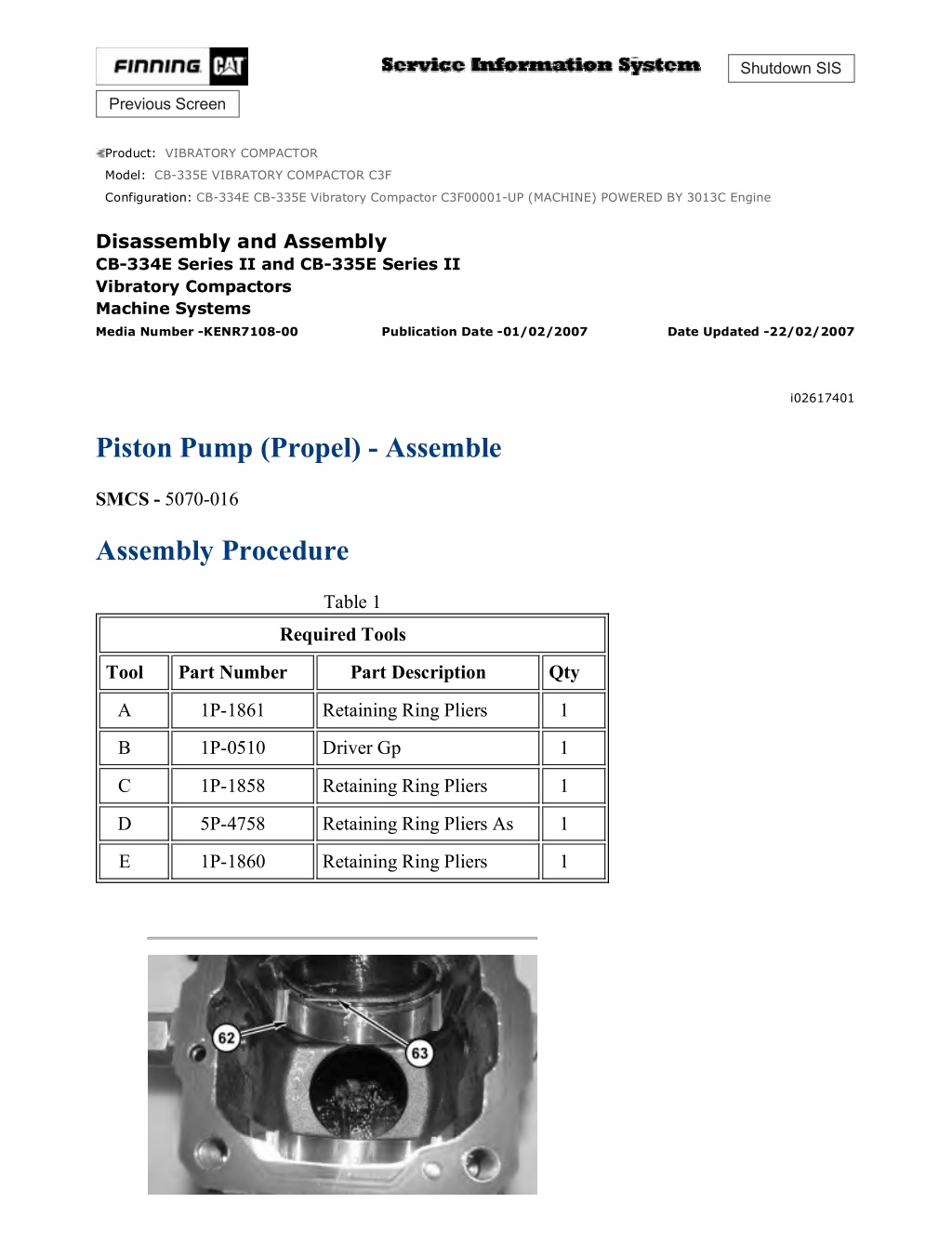

CB-334E CB-335E Vibratory Compactor C3F00001-UP (MACHINE) POWERED B... 2/15 Illustration 1 g01310841 Illustration 2 g01310842 1. Install pin (63) and plug (64) . 2. Install races (62) . Illustration 3 g01310840 3. Install bearing (61) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/16

CB-334E CB-335E Vibratory Compactor C3F00001-UP (MACHINE) POWERED B... 3/15 Illustration 4 g01310839 4. Install controller (60), bolt (59), bearing (57), and pin (58) . Illustration 5 g01310838 5. Install pin (58), bearing (57), and swashplate assembly (56) . Illustration 6 g01311535 6. Raise the temperature of bearing (55) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/16

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

CB-334E CB-335E Vibratory Compactor C3F00001-UP (MACHINE) POWERED B... 4/15 7. Install bearing (55) onto shaft (53) . 8. Use Tooling (E) in order to install retaining ring (54) . Illustration 7 g01310833 9. Install shaft (53) and O-ring seal (52) . Illustration 8 g01310832 10. Install lip seal (51) into cover (50) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/16

CB-334E CB-335E Vibratory Compactor C3F00001-UP (MACHINE) POWERED B... 5/15 Illustration 9 g01310830 11. Install cover (50) . 12. Use Tooling (D) in order to Install retaining ring (49) . Illustration 10 g01310849 Illustration 11 g01311061 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/16

CB-334E CB-335E Vibratory Compactor C3F00001-UP (MACHINE) POWERED B... 6/15 Personal injury can result from being struck by parts propelled by a released spring force. Make sure to wear all necessary protective equipment. Follow the recommended procedure and use all recommended tooling to release the spring force. 13. Install washer (46), spring (47), and washer (48) into barrel (42) . 14. Use Tooling (B), Tooling (C), and a suitable press in order to install retaining ring (45) . Illustration 12 g01310844 15. Install pins (44) and retainer (43) . Illustration 13 g01310848 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/16

CB-334E CB-335E Vibratory Compactor C3F00001-UP (MACHINE) POWERED B... 7/15 16. Install bearing (41) onto barrel (42) . Illustration 14 g01310846 17. Install pistons (39) into retaining plate (40) . Illustration 15 g01310845 18. Install pistons (39) and retaining plate (40) onto the barrel. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/16

CB-334E CB-335E Vibratory Compactor C3F00001-UP (MACHINE) POWERED B... 8/15 Illustration 16 g01310843 19. Install rotating group (37) and gasket (38) . Illustration 17 g01310837 20. Install block (35) and gasket (36) . Illustration 18 g01310828 Personal injury can result from being struck by parts propelled by a released spring force. Make sure to wear all necessary protective equipment. Follow the recommended procedure and use all recommended tooling to release the spring force. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/16

CB-334E CB-335E Vibratory Compactor C3F00001-UP (MACHINE) POWERED B... 9/15 21. Install spring (31), washer (32), and nuts (33) onto bolt (34) . Illustration 19 g01310826 Personal injury can result from being struck by parts propelled by a released spring force. Make sure to wear all necessary protective equipment. Follow the recommended procedure and use all recommended tooling to release the spring force. 22. Use Tooling (A) in order to install retaining ring (30) . Illustration 20 g01310825 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/16

CB-334E CB-335E Vibratory Compactor C3F00001-UP (MACHINE) POWERED ... 10/15 23. Install O-ring seal (29) onto cover (25) . Illustration 21 g01310823 24. Install cover (25), washer (27), and nut (28) onto piston assembly (26) . Illustration 22 g01310822 25. Install the O-ring seal, cover (25), and bolts (24) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/16

CB-334E CB-335E Vibratory Compactor C3F00001-UP (MACHINE) POWERED ... 11/15 Illustration 23 g01310821 26. Install the O-ring seal, cover (23), and bolts (22) . Illustration 24 g01310819 27. Install cartridge (21) . Illustration 25 g01310818 28. Install controller (18), bolts (17), coil (19), and nut (20) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/16

CB-334E CB-335E Vibratory Compactor C3F00001-UP (MACHINE) POWERED ... 12/15 Illustration 26 g01311069 Personal injury can result from being struck by parts propelled by a released spring force. Make sure to wear all necessary protective equipment. Follow the recommended procedure and use all recommended tooling to release the spring force. 29. Install the O-ring seals, poppet (14), spring (13), retainers (11), and plug assembly (9) . 30. Repeat Step 29 for the opposite side. 31. Install the O-ring seals, check valve (10), and check valve (12) . 32. Install the O-ring seals, plug (16), and plugs (15) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/16

CB-334E CB-335E Vibratory Compactor C3F00001-UP (MACHINE) POWERED ... 13/15 Illustration 27 g01310817 33. Install port plate (8) . Illustration 28 g01310813 Personal injury can result from being struck by parts propelled by a released spring force. Make sure to wear all necessary protective equipment. Follow the recommended procedure and use all recommended tooling to release the spring force. 34. Install head (7) and bolts (6) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/16

CB-334E CB-335E Vibratory Compactor C3F00001-UP (MACHINE) POWERED ... 14/15 Illustration 29 g01310811 35. Install O-ring seal (5) . Illustration 30 g01310810 36. Install cover (3) and O-ring seal (4) . Illustration 31 g01310809 37. Install cover (2) and bolts (1) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/16

CB-334E CB-335E Vibratory Compactor C3F00001-UP (MACHINE) POWERED ... 15/15 End By: Install the piston pump. Refer to Disassembly and Assembly, "Piston Pump (Propel) - Install". Copyright 1993 - 2021 Caterpillar Inc. Mon Aug 16 23:30:16 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/16

CB-334E CB-335E Vibratory Compactor C3F00001-UP (MACHINE) POWERED B... 1/4 Shutdown SIS Previous Screen Product: VIBRATORY COMPACTOR Model: CB-335E VIBRATORY COMPACTOR C3F Configuration: CB-334E CB-335E Vibratory Compactor C3F00001-UP (MACHINE) POWERED BY 3013C Engine Disassembly and Assembly CB-334E Series II and CB-335E Series II Vibratory Compactors Machine Systems Media Number -KENR7108-00 Publication Date -01/02/2007 Date Updated -22/02/2007 i02624338 Piston Pump (Propel) - Install SMCS - 5070-012 Installation Procedure Illustration 1 g01315179 1. Install the O-ring seal and gear pump (1) to piston pump (4) and install bolts (12) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/16

CB-334E CB-335E Vibratory Compactor C3F00001-UP (MACHINE) POWERED B... 2/4 Illustration 2 g01315082 2. Attach a suitable lifting device to piston pump (4). Install piston pump (4) and gear pump (1) as a unit. Install bolts (11). The weight of the piston pump and the gear pump is approximately 61 kg (135 lb). Illustration 3 g01315081 3. Connect hose assembly (10) to piston pump (4) . Illustration 4 g01315080 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/16

CB-334E CB-335E Vibratory Compactor C3F00001-UP (MACHINE) POWERED B... 3/4 4. Connect hose assembly (9), hose assemblies (8), and hose assembly (7) to piston pump (4) . Illustration 5 g01315079 5. Connect hose assemblies (6) to piston pump (4) . Illustration 6 g01315062 6. Connect harness assembly (5) to piston pump (4) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/16

CB-334E CB-335E Vibratory Compactor C3F00001-UP (MACHINE) POWERED B... 4/4 Illustration 7 g01315008 7. Connect hose assembly (3) and hose assemblies (2) to gear pump (1) . 8. Fill the hydraulic oil tank with hydraulic oil. Refer to Operation and Maintenance Manual for the correct procedure. Copyright 1993 - 2021 Caterpillar Inc. Mon Aug 16 23:31:11 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/16

CB-334E CB-335E Vibratory Compactor C3F00001-UP (MACHINE) POWERED B... 1/6 Shutdown SIS Previous Screen Product: VIBRATORY COMPACTOR Model: CB-335E VIBRATORY COMPACTOR C3F Configuration: CB-334E CB-335E Vibratory Compactor C3F00001-UP (MACHINE) POWERED BY 3013C Engine Disassembly and Assembly CB-334E Series II and CB-335E Series II Vibratory Compactors Machine Systems Media Number -KENR7108-00 Publication Date -01/02/2007 Date Updated -22/02/2007 i02624562 Drum and Drum Support - Remove SMCS - 6605-011-S4; 6605-011 Removal Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 6V-6146 Load Leveling Beam 1 B 138-7574 Link Bracket 2 C 1P-2321 Combination Puller 1 Start By: A. Remove the vibratory motor. Refer to Disassembly and Assembly, "Gear Motor (Vibratory) - Remove". Hot oil and hot components can cause personal injury. Do not allow hot oil or hot components to contact skin. At operating temperature, the engine coolant is hot and under pressure. Steam can cause personal injury. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/16

CB-334E CB-335E Vibratory Compactor C3F00001-UP (MACHINE) POWERED B... 2/6 Check the coolant level only after the engine has been stopped and the cooling system pressure cap is cool enough to touch with your bare hand. Remove the cooling system pressure cap slowly to relieve pressure. Cooling system conditioner contains alkali. Avoid contact with the skin and eyes to prevent personal injury. NOTICE Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids. Refer to Special Publication, NENG2500, "Caterpillar Tools and Shop Products Guide" for tools and supplies suitable to collect and contain fluids on Caterpillar products. Dispose of all fluids according to local regulations and mandates. Note: Put identification marks on all hoses, on all hose assemblies, on all wires, and on all tube assemblies for installation purposes. Plug all hose assemblies and all tube assemblies. This helps to prevent fluid loss, and this helps to keep contaminants from entering the system. Illustration 1 g00622269 1. Disconnect water supply hose (1) from the spray bar. 2. Remove bolts (3) and remove the scraper and spray bar assembly (2) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/16

CB-334E CB-335E Vibratory Compactor C3F00001-UP (MACHINE) POWERED B... 3/6 Illustration 2 g01315304 3. Remove bolts (4) and cover (5) from the drum support. 4. Disconnect hose assemblies (6) from piston motor (7) . 5. Move the hose assemblies out of the way on both sides of the machine. Illustration 3 g01082270 6. Attach Tooling (A), Tooling (B), and a suitable lifting device to each drum support, as shown. The combined weight of the drum and drum supports is approximately 675 kg (1490 lb). 7. Use the suitable lifting device to slightly raise the drum off the ground. Place suitable blocks under the frame, as shown. Lower the machine so the machine rests on the wood blocks. Maintain a small amount of tension in the lifting chains. 8. Remove bolts (8) which fasten the right and left drum supports to the machine. 9. Use the suitable lifting device to carefully lower the drum away from the machine. 10. Use the suitable lifting device to carefully move the drum away from the machine. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/16

CB-334E CB-335E Vibratory Compactor C3F00001-UP (MACHINE) POWERED B... 4/6 Illustration 4 g01083109 11. Block the drum, as shown. 12. Attach a suitable lifting device to drum support (9). The weight of the drum support is approximately 66 kg (146 lb). 13. Remove bolts (10) and use a hoist to remove drum support (12) . Illustration 5 g01083126 14. Attach a suitable lifting device to drum support (vibratory motor side) (11). The weight of drum support (11) and plate assembly (13) is approximately 135 kg (298 lb). 15. Remove bolts (12) and use a suitable lifting device to remove drum support (11) and plate assembly (11) from the drum. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/16

CB-334E CB-335E Vibratory Compactor C3F00001-UP (MACHINE) POWERED B... 5/6 Illustration 6 g01083137 16. Position drum support (11) and attach a suitable lifting device, as shown. Note: Mark plate (15) and drum support (11) for assembly purposes. 17. Remove bolts (14) and remove plate (15) . Illustration 7 g01083150 18. Remove retaining plate (16) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/16

CB-334E CB-335E Vibratory Compactor C3F00001-UP (MACHINE) POWERED B... 6/6 Illustration 8 g01083207 19. Use a Tooling (C) in order to separate drum support (11) from plate assembly (13) . Copyright 1993 - 2021 Caterpillar Inc. Mon Aug 16 23:32:07 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/16

CB-334E CB-335E Vibratory Compactor C3F00001-UP (MACHINE) POWERED B... 1/5 Shutdown SIS Previous Screen Product: VIBRATORY COMPACTOR Model: CB-335E VIBRATORY COMPACTOR C3F Configuration: CB-334E CB-335E Vibratory Compactor C3F00001-UP (MACHINE) POWERED BY 3013C Engine Disassembly and Assembly CB-334E Series II and CB-335E Series II Vibratory Compactors Machine Systems Media Number -KENR7108-00 Publication Date -01/02/2007 Date Updated -22/02/2007 i05006661 Drum and Drum Support - Install SMCS - 6605-012-S4; 6605-012 Installation Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 6V-6146 Load Leveling Beam 1 B 138-7574 Load Leveling Beam 1 C - Loctite 5127 - Illustration 1 g01083207 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/16

CB-334E CB-335E Vibratory Compactor C3F00001-UP (MACHINE) POWERED B... 2/5 1. Position drum support (11) onto plate assembly (13) . Illustration 2 g01083150 2. Install retaining plate (16) . Note: Fill the cavity of retaining plate (16) which faces toward the bearing with grease. Illustration 3 g01083137 3. Apply Tooling (C) to the mating surfaces of plate (15) and drum support (11) . Position retaining plate (16) onto drum support (11) . Install bolts (14) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/16

CB-334E CB-335E Vibratory Compactor C3F00001-UP (MACHINE) POWERED B... 3/5 Illustration 4 g01083126 4. Attach a suitable lifting device to drum support (11) . The weight of the drum support (11) is approximately 135 kg (298 lb). 5. Position drum support (11) and plate assembly (13) , as shown. The large opening on plate assembly (13) should be in-line with the welded boss on the opposite side of the drum. 6. Install bolts (12) which fasten plate assembly (13) to the drum. Illustration 5 g01083109 7. Attach a suitable lifting device to drum support (9) . The weight of drum support (9) is approximately 66 kg (146 lb). 8. Use the suitable lifting device to position drum support (9) , as shown. Install bolts (10) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/16

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

CB-334E CB-335E Vibratory Compactor C3F00001-UP (MACHINE) POWERED B... 4/5 Illustration 6 g01082270 9. Attach Tooling (A) , Tooling (B) , and a suitable lifting device to each drum support, as shown. The combined weight of the drum and drum supports is approximately 675 kg (1490 lb). 10. Use the suitable lifting device to carefully position the drum and drum supports to the original location. 11. Install bolts (8) which fasten the right and left drum supports to the machine. 12. Use the suitable lifting device to raise the machine from the suitable blocks. Remove the suitable blocks and carefully lower the machine to the ground. 13. Move all the hose assemblies to the original position. Note: Repeat step 13 for the opposite side. Illustration 7 g01315304 14. Connect hose assemblies (6) to piston motor (7) . 15. Position cover (5) onto the drum support and install bolts (4) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/16

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com