Caterpillar Cat CB-534D, CB-534DXW Vibratory Compactor (Prefix FGH) Service Repair Manual Instant Download

Please open the website below to get the complete manualnn//

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

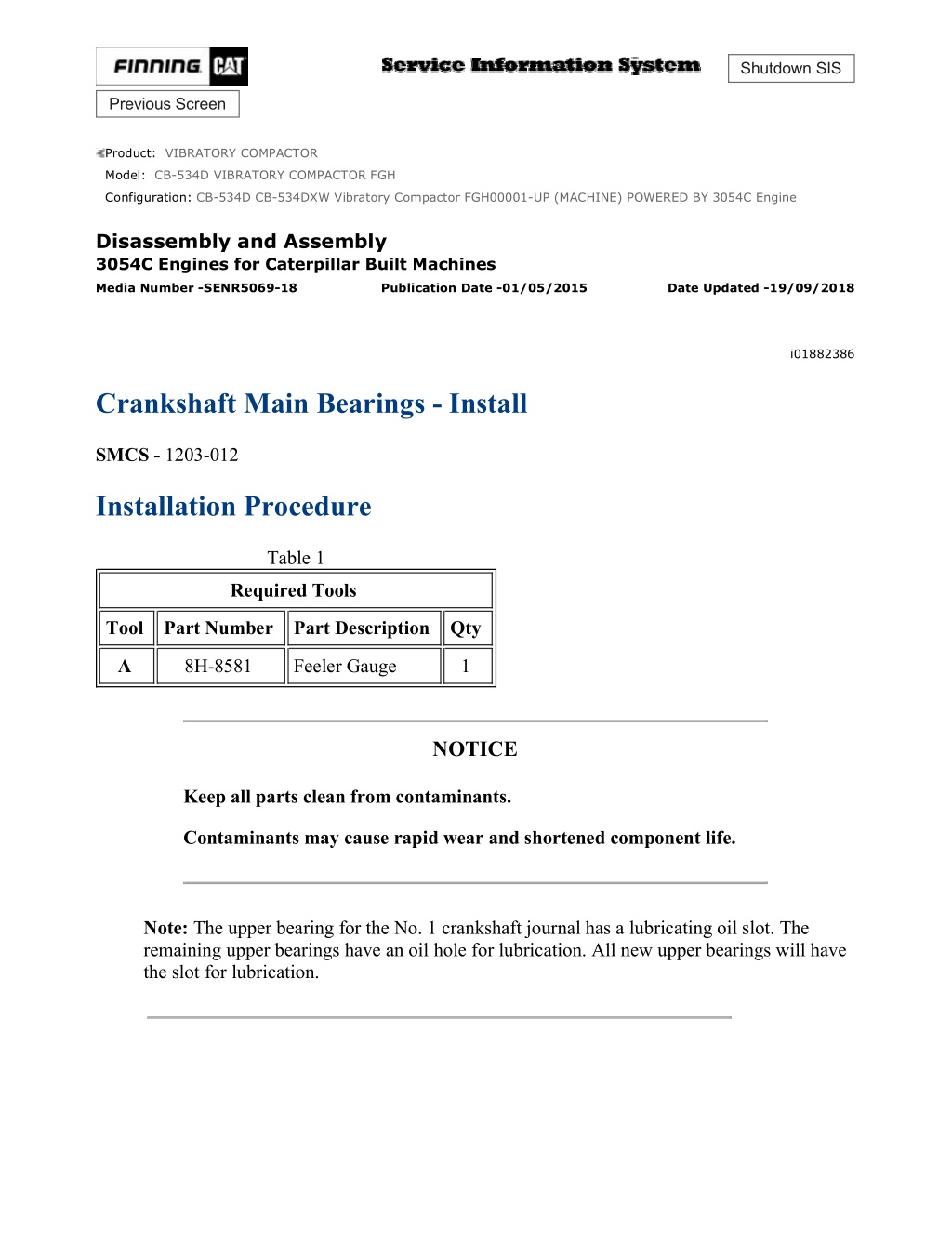

CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERE... 1/5 Shutdown SIS Previous Screen Product: VIBRATORY COMPACTOR Model: CB-534D VIBRATORY COMPACTOR FGH Configuration: CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERED BY 3054C Engine Disassembly and Assembly 3054C Engines for Caterpillar Built Machines Media Number -SENR5069-18 Publication Date -01/05/2015 Date Updated -19/09/2018 i01882386 Crankshaft Main Bearings - Install SMCS - 1203-012 Installation Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 8H-8581 Feeler Gauge 1 NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. Note: The upper bearing for the No. 1 crankshaft journal has a lubricating oil slot. The remaining upper bearings have an oil hole for lubrication. All new upper bearings will have the slot for lubrication. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/29

CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERE... 2/5 Illustration 1 g00934767 1. Clean upper main bearing (4) and lubricate the bearing surface with clean engine oil. Note: Ensure that the upper halves of the main bearings are installed so that the bearing tabs fit into the notch in the cylinder block. NOTICE Only the upper half of the main bearing has lubrication holes. Make sure the upper half of the main bearing is installed correctly in the cylinder block to ensure proper lubrication. 2. Slide upper main bearing (4) into position between the crankshaft journal and the cylinder block. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/29

CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERE... 3/5 Illustration 2 g00934803 3. Clean main bearing cap (2) and lower main bearing (3). Lubricate the bearing surface of lower main bearing (3) with clean engine oil. Note: Ensure that the lower halves of the main bearings are installed so that the bearing tabs fit into the notch in the main bearing caps. 4. Install lower main bearing (3) in main bearing cap (2). Illustration 3 g00947861 5. Install the upper half of thrust washer (6) on each side of the center main bearing in the cylinder block. The grooves on the thrust washer must be located against the crankshaft. If necessary, move the crankshaft to the front or to the rear in order to install the thrust washer. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/29

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERE... 4/5 Illustration 4 g00934744 6. Install the lower half of thrust washer (5) on each side of the center main bearing cap. The grooves on the thrust washer must be located against the crankshaft. Illustration 5 g00947823 7. Install main bearing caps (2). Lubricate the threads of bolts (1) with clean engine oil. 8. Install bolts (1). Tighten bolts (1) to a torque of 245 N m (181 lb ft). 9. Rotate the crankshaft in order to ensure that the crankshaft turns freely. 10. Repeat Steps 1 through 9 for the remaining main bearings. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/29

CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERE... 5/5 Illustration 6 g00975012 11. Check the crankshaft end play. Use a prybar to move the crankshaft toward the front of the engine. Use Tooling (A) to measure the end play between rear thrust washer (5) and the crankshaft. The maximum permissible crankshaft end play is 0.51 mm (0.020 inch). Note: If the crankshaft was not removed for the rear main bearing removal, the following components must be installed: bridge assembly, rear oil seal housing, flywheel housing and flywheel. End By: a. Install the engine oil pump. Refer to Disassembly and Assembly, "Engine Oil Pump - Install". Copyright 1993 - 2021 Caterpillar Inc. Thu Apr 29 21:35:32 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/29

CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERE... 1/3 Shutdown SIS Previous Screen Product: VIBRATORY COMPACTOR Model: CB-534D VIBRATORY COMPACTOR FGH Configuration: CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERED BY 3054C Engine Disassembly and Assembly 3054C Engines for Caterpillar Built Machines Media Number -SENR5069-18 Publication Date -01/05/2015 Date Updated -19/09/2018 i01882243 Crankshaft - Remove SMCS - 1202-011 Removal Procedure Start By: a. Remove the engine oil pump. Refer to Disassembly and Assembly, "Engine Oil Pump - Remove". b. Remove the front housing. Refer to Disassembly and Assembly, "Housing (Front) - Remove". c. Remove the flywheel housing. Refer to Disassembly and Assembly, "Flywheel Housing - Remove and Install". d. Remove the housing for the crankshaft rear seal. Refer to Disassembly and Assembly, "Crankshaft Rear Seal - Remove". NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/29

CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERE... 2/3 Illustration 1 g00975296 1. Remove socket head bolts (1) from the bridge. 2. Remove bridge (2) from the cylinder block. Note: Make sure that the main bearing caps and the connecting rod caps are marked for the location and direction for installation. 3. Remove main bearing cap bolts (3). 4. Remove main bearing caps (4) from the cylinder block. Remove the bearings from the main bearing caps. Keep the main bearings with the respective main bearing cap. 5. Remove bolts (5) from the connecting rods. Note: Do Not reuse bolts (5). Use new bolts in order to secure the connecting rod cap for reassembly. 6. Remove connecting rod bearing caps (6) from the connecting rods. Remove the bearings from the connecting rod bearing caps. Keep the connecting rod bearings with the respective connecting rod bearing cap. NOTICE Do not allow the connecting rods to strike the piston cooling jets. Damage or misalignment may occur. 7. Push the piston assemblies into the cylinder bores. 8. Attach lifting straps and a suitable lifting device to the crankshaft. Lift the crankshaft out of the cylinder block. The weight of the crankshaft is approximately 32 kg (70 lb). Do not scratch any of the finished surfaces on the crankshaft. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/29

CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERE... 3/3 Illustration 2 g00975313 9. Remove the upper main bearings (7). Remove the upper thrust washers from the center main bearing block. Keep the upper main bearings with the respective main bearing caps. Illustration 3 g00975478 10. Remove lower main bearings (8) from main bearing caps (4). Remove the lower thrust washers from the center main bearing cap. Keep the lower main bearings with the respective main bearing cap. Copyright 1993 - 2021 Caterpillar Inc. Thu Apr 29 21:36:28 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/29

CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERE... 1/7 Shutdown SIS Previous Screen Product: VIBRATORY COMPACTOR Model: CB-534D VIBRATORY COMPACTOR FGH Configuration: CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERED BY 3054C Engine Disassembly and Assembly 3054C Engines for Caterpillar Built Machines Media Number -SENR5069-18 Publication Date -01/05/2015 Date Updated -19/09/2018 i05819083 Crankshaft - Install SMCS - 1202-012 Installation Procedure Table 1 Required Tools Tool Part Number Part Description Qty A - Loctite 5900 - B 8H-8581 Feeler Gauge 1 C 8T-3052 Degree Wheel 1 NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. Note: The upper bearing for the No. 1 crankshaft journal has a lubricating oil slot. The remaining upper bearings have an oil hole for lubrication. All new upper bearings will have the slot for lubrication. 1. If necessary, install the pistons and connecting rods. Refer to Disassembly and Assembly Manual, "Pistons and Connecting Rods - Install". 2. Remove the setscrews (5) from the connecting rods and then remove the connecting rod caps (6) from the connecting rods. Discard the setscrews (5) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/29

CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERE... 2/7 3. Ensure that all of the lubrication passages are clean and free of debris. Illustration 1 g01154512 4. Install upper main bearings (8) . The bearing tabs for the upper main bearings must be located in the correct position in the cylinder block. Lubricate upper main bearings (8) with clean engine oil. 5. Clean the upper half of the thrust washers and lubricate the upper half of thrust washers. Place the upper half of the thrust washer in both sides in the recess in the cylinder block of the center main bearing. The grooves on the thrust washer must be located against the crankshaft. 6. Ensure that the main bearing journals and the connecting rod bearing journals of the crankshaft are clean. Attach lifting straps and a suitable lifting device in order to position the crankshaft in the cylinder block. The weight of the crankshaft is approximately 32 kg (70 lb). Do not scratch any of the finished surfaces on the crankshaft. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/29

CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERE... 3/7 Illustration 2 g01154515 7. Clean the lower main bearings. Install the lower main bearings (9) in the main bearing caps (4) with the bearing tabs in the correct position. Lubricate the lower main bearing caps with clean engine oil. 8. Ensure that the locating dowels (10) for the main bearing caps (4) are in the correct position in the main bearing caps or in the cylinder block. Illustration 3 g01154511 9. Clean the lower half of the thrust washers (7) and lubricate the lower half of thrust washers . Place the lower half of the thrust washers (7) in both sides of the center main bearing cap (4) . The grooves on the thrust washer must be located against the crankshaft. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/29

CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERE... 4/7 Illustration 4 g00975374 10. Install the main bearing caps (4) in the position that was marked during the removal process. All of the bearing tabs for the main bearings should be on the same side. Install the main bearing cap bolts (3) . Tighten the bolts to a torque of 245 20 N m (180 14 lb ft). 11. Ensure that the upper connecting rod bearings are centered in the connecting rod. Install the lower connecting rod bearings in the connecting rod cap. Lubricate the bearing faces with clean engine oil. Note: Do not reuse the old setscrews (5) in order to secure the connecting rod cap (6) . Note: Ensure that the etched number on the connecting rod bearing cap matches the etched number on the connecting rod . Ensure that the etched numbers are on the same side. 12. Install the connecting rod caps (6) . Install new setscrews (5) in the connecting rod. Tighten the setscrews evenly to a torque of 18 N m (13 lb ft). 13. Tighten the setscrews evenly to a torque of 70 N m (52 lb ft). 14. Use Tooling (C) to achieve the correct final torque. Note: If Tooling (C) is not used, place an index mark on each bolt. 15. Turn the setscrews for an additional 120 degrees. 16. Rotate the crankshaft in order to ensure that there is no binding. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/29

CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERE... 5/7 Illustration 5 g00975426 Illustration 6 g00541498 17. Clean the bridge and the face of the cylinder block. Apply a thin bead of Tooling (A) on the corners of the seat for the bridge. Also apply Tooling (A) around the thread holes in the seat for the bridge. Use the following steps when you apply Tooling (A) to the cylinder block and the bridge. a. Apply a 3.0 mm (0.12 inch) bead of Tooling (A) along the corner of the top recess in the cylinder block. Note: The maximum protrusion for the bridge (2) from the outside of the cylinder block is 0.075 mm (0.0029 inch). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/29

CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERE... 6/7 b. Install the bridge (2) and the rubber seals, if equipped. The rubber seals will sit higher than the bridge when the seals are correctly installed. Use a straight edge to line up the bridge with the face of the cylinder block. Tighten the socket head screws (1) to a torque of 16 N m (12 lb ft). Tighten the socket head screws evenly. c. When the bridge is positioned and the socket head screws have been tightened, inject Tooling (A) in the groove that is at each end of the bridge. The groove must be completely filled. d. When the gasket for the oil pan is removed, damage may occur to the existing seal in the grooves of the bridge. If the seal is damaged, apply a sufficient amount of Tooling (A) in order to fill the grooves. Illustration 7 g00975364 18. Check the crankshaft end play. Use a prybar to move the crankshaft toward the front of the engine. Use Tooling (B) to measure the end play between the rear thrust washer and the crankshaft. The maximum permissible crankshaft end play is 0.51 mm (0.020 inch). NOTICE If the crankshaft has been reground or if the crankshaft has been replaced, the height of the piston above the cylinder block must be inspected. It is necessary to remove the cylinder head in order to inspect the height of the piston above the cylinder block. 19. Check the height of the piston above the top face of the cylinder block. Refer to Testing and Adjusting, "Piston Height - Inspect". https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/29

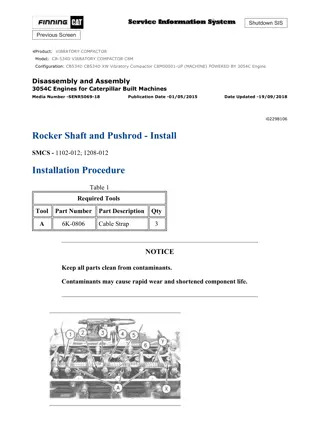

CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERE... 7/7 End By: a. If necessary, install the cylinder head. Refer to Disassembly and Assembly Manual, "Cylinder Head - Install". b. Install the rocker shaft and pushrods. Refer to Disassembly and Assembly Manual, "Rocker Shaft and Pushrod - Install". c. Install the housing for the crankshaft rear seal. Refer to Disassembly and Assembly, "Crankshaft Rear Seal - Install". d. Install the flywheel housing. Refer to Disassembly and Assembly, "Flywheel Housing - Remove and Install". e. Install the front housing. Refer to Disassembly and Assembly, "Housing (Front) - Install". f. If the engine is not equipped with a balancer group, install the engine oil pump. Refer to Disassembly and Assembly, "Engine Oil Pump - Install". g. If the engine is equipped with a balancer group, install the balancer group. Refer to Disassembly and Assembly, "Balancer Group - Install". Copyright 1993 - 2021 Caterpillar Inc. Thu Apr 29 21:37:24 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/29

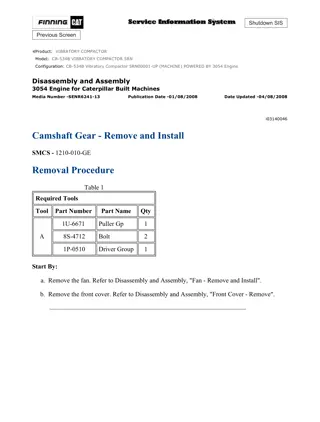

CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERE... 1/3 Shutdown SIS Previous Screen Product: VIBRATORY COMPACTOR Model: CB-534D VIBRATORY COMPACTOR FGH Configuration: CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERED BY 3054C Engine Disassembly and Assembly 3054C Engines for Caterpillar Built Machines Media Number -SENR5069-18 Publication Date -01/05/2015 Date Updated -19/09/2018 i02305687 Crankshaft Gear - Remove and Install SMCS - 1204-010-GE Removal Procedure Table 1 Required Tools Tool Part Number Part Description Qty 8H-0663 Bearing Puller Gp 1 A 126-7175 Push-Puller 1 Start By: a. Remove the front housing. Refer to Disassembly and Assembly, "Housing (Front) - Remove". b. Remove the engine oil pump. Refer to Disassembly and Assembly, "Engine Oil Pump - Remove". NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/29

CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERE... 2/3 Illustration 1 g01157947 1. Use the Tooling (A) to remove the crankshaft gear (1) from the crankshaft (3). Refer to illustration 1. 2. Remove the key (2) from the crankshaft. Installation Procedure NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/29

CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERE... 3/3 1. Heat the crankshaft gear in an oven to 200 C (392 F). 2. Install the key (2) in the crankshaft (3). Install the crankshaft gear (1). Note: The shoulder of the crankshaft gear must be installed toward the front of the crankshaft. End By: a. Install the engine oil pump. Refer to Disassembly and Assembly, "Engine Oil Pump - Install". b. Install the front housing. Refer to Disassembly and Assembly, "Housing (Front) - Install". Copyright 1993 - 2021 Caterpillar Inc. Thu Apr 29 21:38:19 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/29

CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERE... 1/3 Shutdown SIS Previous Screen Product: VIBRATORY COMPACTOR Model: CB-534D VIBRATORY COMPACTOR FGH Configuration: CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERED BY 3054C Engine Disassembly and Assembly 3054C Engines for Caterpillar Built Machines Media Number -SENR5069-18 Publication Date -01/05/2015 Date Updated -19/09/2018 i05977048 Bearing Clearance - Check SMCS - 1203-535; 1219-535 Measurement Procedure Table 1 Required Tools Tool Part Number Part Description Qty Plastic Gauge (Green) 0.025 to 0.076 mm (0.001 to 0.003 inch) 198-9142 1 Plastic Gauge (Red) 0.051 to 0.152 mm (0.002 to 0.006 inch) 198-9143 1 A Plastic Gauge (Blue) 0.102 to 0.229 mm (0.004 to 0.009 inch) 198-9144 1 Plastic Gauge (Yellow) 0.230 to 0.510 mm (0.009 to 0.020 inch) 198-9145 1 Note: Plastic gauge may not be necessary when the engine is in the chassis. NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/29

CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERE... 2/3 Note: Cat does not recommend the checking of the actual bearing clearances particularly on small engines. This is because of the possibility of obtaining inaccurate results and the possibility of damaging the bearing or the journal surfaces. Each Cat engine bearing is quality checked for specific wall thickness. Note: The measurements should be within specifications and the correct bearings should be used. If the crankshaft journals and the bores for the block and the rods were measured during disassembly, no further checks are necessary. However, if the technician still wants to measure the bearing clearances, Tooling (A) is an acceptable method. Tooling (A) is less accurate on journals with small diameters if clearances are less than 0.10 mm (0.004 inch). NOTICE Lead wire, shim stock or a dial bore gauge can damage the bearing surfaces. The technician must be very careful to use Tooling (A) correctly. The following points must be remembered: Ensure that the backs of the bearings and the bores are clean and dry. Ensure that the bearing locking tabs are properly seated in the tab grooves. The crankshaft must be free of oil at the contact points of Tooling (A). 1. Put a piece of Tooling (A) on the crown of the bearing that is in the cap. Note: Do not allow Tooling (A) to extend over the edge of the bearing. 2. Use the correct torque-turn specifications in order to install the bearing cap. Do not use an impact wrench. Be careful not to dislodge the bearing when the cap is installed. Note: Do not turn the crankshaft when Tooling (A) is installed. 3. Carefully remove the cap, but do not remove Tooling (A). Measure the width of Tooling (A) while Tooling (A) is in the bearing cap or on the crankshaft journal. Refer to Illustration 1. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/29

CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERE... 3/3 Illustration 1 g01152855 Typical Example 4. Remove all of Tooling (A) before you install the bearing cap. Note: When Tooling (A) is used, the readings can sometimes be unclear. For example, all parts of Tooling (A) are not the same width. Measure the major width in order to ensure that the parts are within the specification range. Refer to Specifications Manual, "Connecting Rod Bearing Journal" and Specifications Manual, "Main Bearing Journal" for the correct clearances. Copyright 1993 - 2021 Caterpillar Inc. Thu Apr 29 21:39:15 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/29

CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERE... 1/3 Shutdown SIS Previous Screen Product: VIBRATORY COMPACTOR Model: CB-534D VIBRATORY COMPACTOR FGH Configuration: CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERED BY 3054C Engine Disassembly and Assembly 3054C Engines for Caterpillar Built Machines Media Number -SENR5069-18 Publication Date -01/05/2015 Date Updated -19/09/2018 i02306203 Coolant Temperature Sensor - Remove and Install SMCS - 1906-010 Removal Procedure NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. NOTICE Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting, and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids. Refer to Special Publication, NENG2500, "Dealer Service Tool Catalog" for tools and supplies suitable to collect and contain fluids on Cat products. Dispose of all fluids according to local regulations and mandates. 1. Drain the coolant from the cooling system to a level below the coolant temperature sensor into a suitable container for storage or disposal. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/29

CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERE... 2/3 Illustration 1 g00975971 2. Disconnect the harness assembly (1). 3. Remove the coolant temperature sensor (2) from the cylinder head. 4. Remove the O-ring seal from the coolant temperature sensor. Installation Procedure NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/29

CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERE... 3/3 Illustration 2 g00975971 1. Install a new O-ring seal on the coolant temperature sensor. Lubricate the O-ring seal with clean engine oil. 2. Install the coolant temperature sensor (2) in the cylinder head. Tighten the coolant temperature sensor to a torque of 20 N m (15 lb ft). 3. Connect the harness assembly (1). 4. Fill the cooling system to the correct level. Refer to Operation and Maintenance, "Refill Capacities" for the cooling system capacity. Copyright 1993 - 2021 Caterpillar Inc. Thu Apr 29 21:40:11 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/29

CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERE... 1/3 Shutdown SIS Previous Screen Product: VIBRATORY COMPACTOR Model: CB-534D VIBRATORY COMPACTOR FGH Configuration: CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERED BY 3054C Engine Disassembly and Assembly 3054C Engines for Caterpillar Built Machines Media Number -SENR5069-18 Publication Date -01/05/2015 Date Updated -19/09/2018 i01923855 Engine Oil Pressure Sensor - Remove and Install SMCS - 1924-010 Removal Procedure NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. NOTICE Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting, and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids. Refer to Special Publication, NENG2500, "Dealer Service Tool Catalog" for tools and supplies suitable to collect and contain fluids on Cat products. Dispose of all fluids according to local regulations and mandates. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/29

CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERE... 2/3 Illustration 1 g00976014 1. Disconnect harness assembly (1). 2. Remove engine oil pressure sensor (2). 3. Remove the O-ring seal from the engine oil pressure sensor. Installation Procedure NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/29

CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERE... 3/3 Illustration 2 g00976014 1. Install a new O-ring seal on the engine oil pressure sensor. Lubricate the O-ring seal with clean engine oil. 2. Install engine oil pressure sensor (2). Tighten the engine oil pressure sensor to a torque of 10 N m (89 lb in). 3. Connect harness assembly (1). 4. Fill the engine oil pan to the correct level that is indicated on the engine oil level gauge. Copyright 1993 - 2021 Caterpillar Inc. Thu Apr 29 21:41:07 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/29

CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERE... 1/3 Shutdown SIS Previous Screen Product: VIBRATORY COMPACTOR Model: CB-534D VIBRATORY COMPACTOR FGH Configuration: CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERED BY 3054C Engine Disassembly and Assembly 3054C Engines for Caterpillar Built Machines Media Number -SENR5069-18 Publication Date -01/05/2015 Date Updated -19/09/2018 i02306266 Glow Plugs - Remove and Install SMCS - 1412-010 Removal Procedure NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. 1. Turn the disconnect switch to the OFF position. 2. Remove the fuel injection nozzle cover. Refer to Disassembly and Assembly Manual, "Fuel Injection Nozzle Cover - Remove and Install". 3. Remove the fuel injection lines. Refer to this Disassembly and Assembly Manual, "Fuel Injection Lines - Remove". https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/29

CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERE... 2/3 Illustration 1 g01155252 4. Disconnect the harness assembly from the connector (4) on the bus bar (1). 5. Loosen the nuts (2) that secure the bus bar (1) to the glow plugs (3). 6. Remove the bus bar (1) from the glow plugs (3). 7. Remove the glow plug (3) from the cylinder head. Installation Procedure NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/29

CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERE... 3/3 Illustration 2 g01155252 1. Clean the threads of the glow plug (3). 2. Install the glow plug (3) in the cylinder head. Tighten the glow plug to a torque of 18 N m (13 lb ft). 3. Position the bus bar (1) on the glow plugs (3). Tighten nuts (2) on the glow plugs to a torque of 2 N m (17 lb in). 4. Connect the harness assembly to the connector (4) on the bus bar (1). 5. Install the fuel injection lines. Refer to Disassembly and Assembly Manual, "Fuel Injection Lines - Install". 6. Install the fuel injection nozzle cover. Refer to Disassembly and Assembly Manual, "Fuel Injection Nozzle Cover - Remove and Install". 7. Turn the disconnect switch to the ON position. Copyright 1993 - 2021 Caterpillar Inc. Thu Apr 29 21:42:02 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/29

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERE... 1/2 Shutdown SIS Previous Screen Product: VIBRATORY COMPACTOR Model: CB-534D VIBRATORY COMPACTOR FGH Configuration: CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERED BY 3054C Engine Disassembly and Assembly 3054C Engines for Caterpillar Built Machines Media Number -SENR5069-18 Publication Date -01/05/2015 Date Updated -19/09/2018 i02308847 V-Belts - Remove and Install SMCS - 1357-010 Removal Procedure Illustration 1 g00932341 Typical example 1. If necessary, remove the setscrews (6) that fasten the fan guard (3) to the fan shroud. Remove the fan guard (3). 2. Loosen the nut (1), the clamping screw (4), and the setscrew (7). Slide the alternator (2) toward the engine. Note: If the nut (1) is loose on the setscrew, remove the nut and discard the nut. 3. Maneuver the V-belts (5) around the fan and remove the V-belts. Note: Never replace one V-belt. Always replace sets of V-belts, if equipped. Installation Procedure https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/29

CB-534D CB-534DXW Vibratory Compactor FGH00001-UP (MACHINE) POWERE... 2/2 Illustration 2 g00932341 Typical example 1. Install the V-belts (5) behind the fan and on the correct pulleys. 2. Adjust the tension on the V-belts (5) by moving the alternator (2) away from the engine. After the correct belt tension is set, tighten the clamping screw (4) to a torque of 78 N m (58 lb ft). Refer to Testing and Adjusting, "V-Belt - Test" for the correct tension of the V- belts. Note: If the V-belt cannot be checked with a gauge, press on the V-belt at the center of the longest free length in order to check the deflection. Under a moderate amount of pressure, the V-belt should have a deflection of 10.0 mm (0.40 inch). 3. Tighten the setscrew (7) to a torque of 22 N m (16 lb ft). 4. If necessary, install a new nut (1). Tighten the nut to a torque of 22 N m (16 lb ft). 5. If the fan guard was previously removed, put the fan guard (3) in position on the fan shroud. Install the setscrews (6) that fasten the fan guard to the fan shroud. Copyright 1993 - 2021 Caterpillar Inc. Thu Apr 29 21:42:58 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/29

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com