Caterpillar Cat CB-335D Vibratory Compactor (Prefix D4E) Service Repair Manual Instant Download

Please open the website below to get the complete manualnn//

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

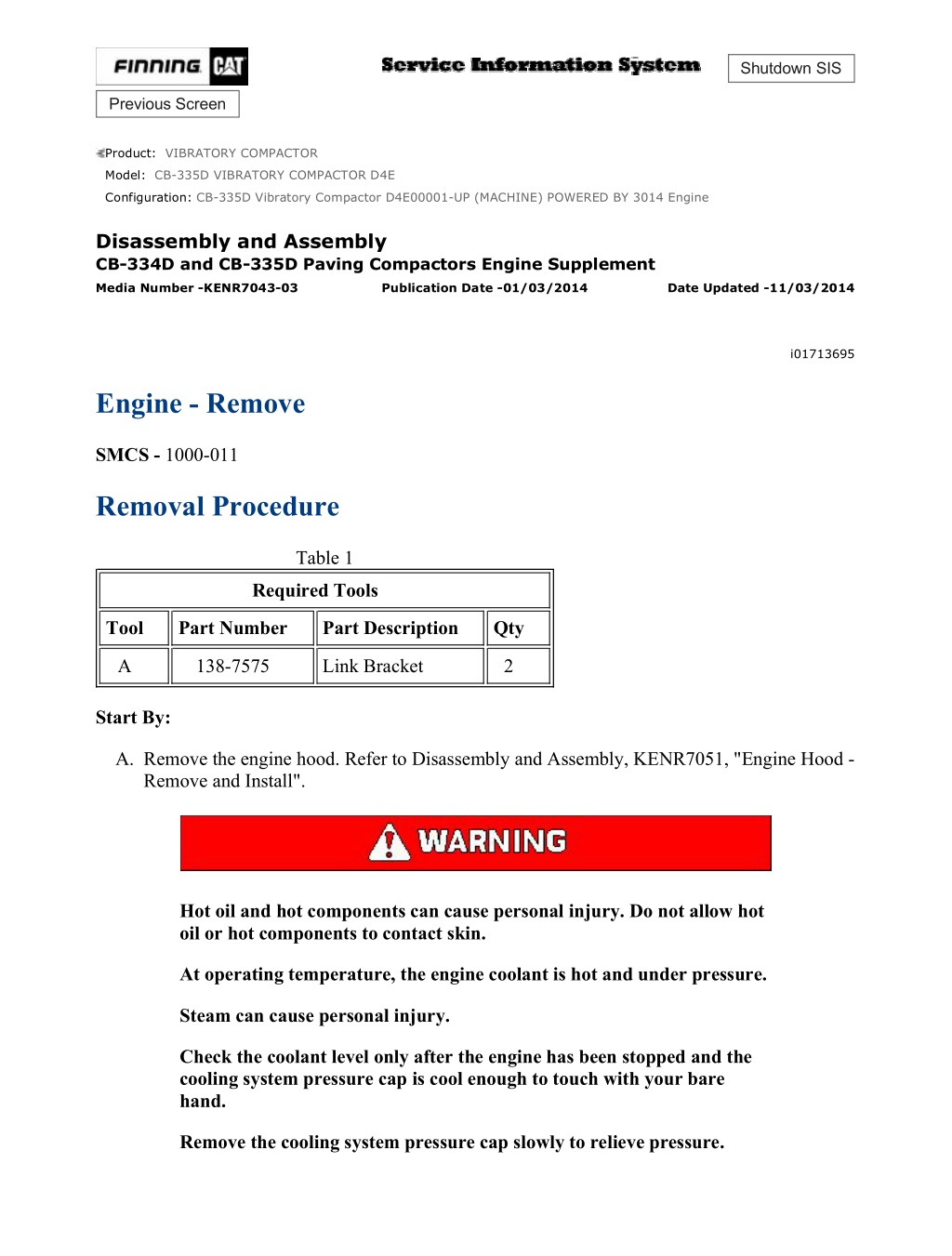

CB-335D Vibratory Compactor D4E00001-UP (MACHINE) POWERED BY 3014 En... 1/11 Shutdown SIS Previous Screen Product: VIBRATORY COMPACTOR Model: CB-335D VIBRATORY COMPACTOR D4E Configuration: CB-335D Vibratory Compactor D4E00001-UP (MACHINE) POWERED BY 3014 Engine Disassembly and Assembly CB-334D and CB-335D Paving Compactors Engine Supplement Media Number -KENR7043-03 Publication Date -01/03/2014 Date Updated -11/03/2014 i01713695 Engine - Remove SMCS - 1000-011 Removal Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 138-7575 Link Bracket 2 Start By: A. Remove the engine hood. Refer to Disassembly and Assembly, KENR7051, "Engine Hood - Remove and Install". Hot oil and hot components can cause personal injury. Do not allow hot oil or hot components to contact skin. At operating temperature, the engine coolant is hot and under pressure. Steam can cause personal injury. Check the coolant level only after the engine has been stopped and the cooling system pressure cap is cool enough to touch with your bare hand. Remove the cooling system pressure cap slowly to relieve pressure. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/14

CB-335D Vibratory Compactor D4E00001-UP (MACHINE) POWERED BY 3014 En... 2/11 Cooling system conditioner contains alkali. Avoid contact with the skin and eyes to prevent personal injury. NOTICE Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids. Refer to Special Publication, NENG2500, "Caterpillar Tools and Shop Products Guide" for tools and supplies suitable to collect and contain fluids on Caterpillar products. Dispose of all fluids according to local regulations and mandates. Note: Put identification marks on all lines, on all hoses, on all wires and on all tubes for installation purposes. Plug all lines, all hoses and all tubes. This will help to prevent fluid loss and this will help to keep contaminants from entering the system. 1. Use the petcock and drain hose that is located on the radiator to drain coolant from the radiator and the engine. The capacity of the 3013 Engine cooling system is 6.7 L (1.8 US gal). The capacity of the 3014 Engine cooling system is 7.3 L (1.9 US gal). Illustration 1 g00610382 2. Loosen the clamp and disconnect battery ground (1) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/14

CB-335D Vibratory Compactor D4E00001-UP (MACHINE) POWERED BY 3014 En... 3/11 Illustration 2 g00610389 3. Remove three bolts (2) and remove the guard (3) for the V-belt. Illustration 3 g00610404 4. Loosen hose clamp (4). Disconnect coolant hose (5) from the engine. Drain any remaining coolant from the cooling system through hose (5) . Illustration 4 g00610422 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/14

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

CB-335D Vibratory Compactor D4E00001-UP (MACHINE) POWERED BY 3014 En... 4/11 5. Loosen hose clamp (7). Disconnect coolant hose (6) from the engine. Illustration 5 g00610430 6. Loosen two hose clamps (9). Remove air intake hose (8) from the engine and the air cleaner housing. Illustration 6 g00610438 7. Remove four bolts (10) and slightly bend exhaust pipe (11) away from the engine. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/14

CB-335D Vibratory Compactor D4E00001-UP (MACHINE) POWERED BY 3014 En... 5/11 Illustration 7 g00610460 8. Disconnect electrical connector (12). Disconnect cable assembly (13) . Illustration 8 g00610568 9. Remove two nuts, two washers, and two electrical connectors (13). Disconnect electrical connector (14) . Illustration 9 g00610612 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/14

CB-335D Vibratory Compactor D4E00001-UP (MACHINE) POWERED BY 3014 En... 6/11 10. Disconnect two electrical connectors (15). Remove three clamps (16) that fasten the wiring harness to the engine. Illustration 10 g00610656 11. Disconnect electrical connector (17) from the fuel shutoff solenoid. Illustration 11 g00610691 12. Remove the nut and disconnect electrical connector (18). Cut cable tie (19) and move the engine wiring harness aside. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/14

CB-335D Vibratory Compactor D4E00001-UP (MACHINE) POWERED BY 3014 En... 7/11 Illustration 12 g00610702 13. Remove bolt (20) which fastens the ground strap (21) from the frame. Illustration 13 g00610713 14. Remove bolt (23) which fastens clamps (22) to the engine. Illustration 14 g00610783 15. Loosen jam nut (24). Remove cotter pin (27) and remove throttle cable (28) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/14

CB-335D Vibratory Compactor D4E00001-UP (MACHINE) POWERED BY 3014 En... 8/11 16. Loosen hose clamp (25) and remove fuel line (26) . Illustration 15 g00612054 17. Loosen hose clamp (30) and remove fuel line (29) . Illustration 16 g00612128 18. Remove bolt (31) which secures the clamp for the hydraulic hose. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/14

CB-335D Vibratory Compactor D4E00001-UP (MACHINE) POWERED BY 3014 En... 9/11 Illustration 17 g00612144 19. Loosen jam nut (36) . 20. Mark the orientation of link (33) for installation purposes. Remove nut (32) and remove link (33). Remove cable (37) from bracket (35) . 21. Remove two bolts (34) and remove bracket (35) . Illustration 18 g00612165 22. Remove two bolts (38) from the clamp which secures the hydraulic hose. Illustration 19 g00613313 23. Place a wood block or place a suitable support block beneath the hydraulic pumps (42) . 24. Remove remaining ten bolts (40) which fasten adapter plate (41) to the engine. Note: Fully unscrew two bolts (40), which support bracket (39), from the engine. Allow the two bolts to remain inserted through bracket (39) and adapter plate (41). This will support the valve group which is attached to bracket (39) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/14

CB-335D Vibratory Compactor D4E00001-UP (MACHINE) POWERED BY 3014 ... 10/11 25. Carefully pry adapter plate (41) away from the engine. Illustration 20 g00613328 26. Attach Tooling (A) and a hoist to the engine, as shown. The weight of the engine is approximately 170 kg (375 lb). Illustration 21 g00613751 27. Remove bolt (43) from the right engine mount. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/14

CB-335D Vibratory Compactor D4E00001-UP (MACHINE) POWERED BY 3014 ... 11/11 Illustration 22 g00613768 28. Remove bolt (44) from the left rear engine mount. Illustration 23 g00613777 29. Remove bolt (45) from the left front engine mount. 30. Carefully raise the engine off the mounts. Be sure that the engine is free from adapter plate (41), all lines, and all harnesses. Remove the engine from the machine. Copyright 1993 - 2021 Caterpillar Inc. Sat Aug 14 22:51:05 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/14

CB-335D Vibratory Compactor D4E00001-UP (MACHINE) POWERED BY 3014 En... 1/11 Shutdown SIS Previous Screen Product: VIBRATORY COMPACTOR Model: CB-335D VIBRATORY COMPACTOR D4E Configuration: CB-335D Vibratory Compactor D4E00001-UP (MACHINE) POWERED BY 3014 Engine Disassembly and Assembly CB-334D and CB-335D Paving Compactors Engine Supplement Media Number -KENR7043-03 Publication Date -01/03/2014 Date Updated -11/03/2014 i01713702 Engine - Install SMCS - 1000-012 Installation Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 138-7575 Link Bracket 2 Illustration 1 g00613969 1. Attach Tooling (A) and a hoist to the engine, as shown. The weight of the engine is approximately 170 kg (375 lb). 2. Carefully lower the engine into the machine onto the mounts. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/14

CB-335D Vibratory Compactor D4E00001-UP (MACHINE) POWERED BY 3014 En... 2/11 Illustration 2 g00613777 3. Install bolt (45) in the left front engine mount. Tighten bolt (45) to a torque of 75 8 N m (55 6 lb ft). Illustration 3 g00613768 4. Install bolt (44) in the left rear engine mount. Tighten bolt (44) to a torque of 75 8 N m (55 6 lb ft). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/14

CB-335D Vibratory Compactor D4E00001-UP (MACHINE) POWERED BY 3014 En... 3/11 Illustration 4 g00613751 5. Install bolt (43) in the right engine mount. Tighten bolt (43) to a torque of 75 8 N m (55 6 lb ft). Illustration 5 g00614071 6. Attach a sling and a hoist around hydraulic pumps (42). Use the hoist in order to position the pump hub into the drive flange which is connected to the engine flywheel. Also, be sure to align the adapter plate (41) onto the engine. Illustration 6 g00613313 7. Install ten bolts (40) which fasten adapter plate (41) and bracket (39) to the engine. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/14

CB-335D Vibratory Compactor D4E00001-UP (MACHINE) POWERED BY 3014 En... 4/11 Illustration 7 g00612165 8. Install the clamp and two bolts (38) . Illustration 8 g00612144 9. Install bracket (35) and two bolts (34) . 10. Install cable (37) onto bracket (35). Install link (33) onto the splined shaft and secure link (33) with nut (32) . 11. Tighten jam nut (36) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/14

CB-335D Vibratory Compactor D4E00001-UP (MACHINE) POWERED BY 3014 En... 5/11 Illustration 9 g00612128 12. Install the clamp and tighten bolt (31) which secures the hydraulic hose. Illustration 10 g00612054 13. Install fuel line (29) and tighten hose clamp (30) . Illustration 11 g00610783 14. Install fuel line (26) and tighten hose clamp (25) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/14

CB-335D Vibratory Compactor D4E00001-UP (MACHINE) POWERED BY 3014 En... 6/11 15. Attach throttle cable (28) and install cotter pin (27). Tighten jam nut (24) . Illustration 12 g00610713 16. Install bolt (23) which fastens clamps (22) to the engine. Illustration 13 g00610702 17. Attach ground strap (21) to the frame and install bolt (20) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/14

CB-335D Vibratory Compactor D4E00001-UP (MACHINE) POWERED BY 3014 En... 7/11 Illustration 14 g00610691 18. Reroute the engine wiring harness to the original location. Install a cable tie (19), as shown. Install electrical connector (18) . Illustration 15 g00610656 19. Install electrical connector (17) onto the fuel shutoff solenoid. Illustration 16 g00610612 20. Install electrical connectors (15). Fasten the wiring harness to the engine with three clamps (16) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/14

CB-335D Vibratory Compactor D4E00001-UP (MACHINE) POWERED BY 3014 En... 8/11 Illustration 17 g00610568 21. Install electrical connector (14). Install two electrical connectors, two washers, and two nuts (13) . Illustration 18 g00610460 22. Connect cable assembly (13) to the starter motor. Install electrical connector (12) . Illustration 19 g00610438 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/14

CB-335D Vibratory Compactor D4E00001-UP (MACHINE) POWERED BY 3014 En... 9/11 23. Align exhaust pipe (11) with the engine and install four bolts (10) . Illustration 20 g00610430 24. Install air intake hose (8) between the engine and the air cleaner housing. Tighten two hose clamps (9) . Illustration 21 g00610422 25. Install coolant hose (6) onto the engine and tighten hose clamp (7) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/14

CB-335D Vibratory Compactor D4E00001-UP (MACHINE) POWERED BY 3014 ... 10/11 Illustration 22 g00610404 26. Install coolant hose (5) onto the engine and tighten hose clamp (4) . Illustration 23 g00610389 27. Install the guard (3) for the V-belt and install three bolts (2) . Illustration 24 g00610382 28. Attach the battery cable to the battery and tighten clamp (1) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/14

CB-335D Vibratory Compactor D4E00001-UP (MACHINE) POWERED BY 3014 ... 11/11 29. Fill the cooling system. Refer to Operation and Maintenance Manual, KEBU7502 for the correct procedure. The capacity of the 3013 Engine cooling system is 6.7 L (1.8 US gal). The capacity of the 3014 Engine cooling system is 7.3 L (1.9 US gal). , End By: Install the engine hood. Refer to Disassembly and AssemblyKENR7051, "Engine Hood - Remove and Install". Copyright 1993 - 2021 Caterpillar Inc. Sat Aug 14 22:52:01 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/14

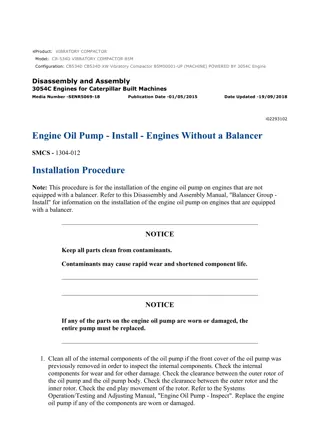

CB-335D Vibratory Compactor D4E00001-UP (MACHINE) POWERED BY 3014 En... 1/3 Shutdown SIS Previous Screen Product: VIBRATORY COMPACTOR Model: CB-335D VIBRATORY COMPACTOR D4E Configuration: CB-335D Vibratory Compactor D4E00001-UP (MACHINE) POWERED BY 3014 Engine Disassembly and Assembly 3003, 3013, 3014 and 3024 Engines for Caterpillar Built Machines Media Number -SENR5027-05 Publication Date -01/05/2005 Date Updated -16/05/2005 i01783524 Fuel Filter Base - Remove SMCS - 1262-011 Removal Procedure NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. NOTICE Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids. Refer to Special Publication, NENG2500, "Caterpillar Tools and Shop Products Guide" for tools and supplies suitable to collect and contain fluids on Caterpillar products. Dispose of all fluids according to local regulations and mandates. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/14

CB-335D Vibratory Compactor D4E00001-UP (MACHINE) POWERED BY 3014 En... 2/3 Illustration 1 g00767792 Typical example 1. Remove fuel filter (5) from the fuel filter base, as follows: a. Remove the collar and cap (1) from the top of fuel filter base (2). This will help prevent spillage of fuel from the fuel filter. b. Hold fuel filter (5) while locking collar (4) is turned in the counterclockwise direction. c. Pull fuel filter (5) from fuel filter base (2) and remove locking collar (4) . 2. Disconnect fuel line (3) from fuel filter base (2). Plug all openings or cap all openings immediately in order to help prevent contamination. Illustration 2 g00767793 Typical example 3. Remove two bolts (6) that fasten fuel filter base (2) to the mounting bracket. 4. Remove fuel filter base (2) from the mounting bracket. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/14

CB-335D Vibratory Compactor D4E00001-UP (MACHINE) POWERED BY 3014 En... 3/3 Note: Some engines may have a hand priming pump on the fuel filter base. Refer to the Disassembly and Assembly, "Fuel Filter Base - Disassemble" topic for information on removing the hand priming pump. Copyright 1993 - 2021 Caterpillar Inc. Sat Aug 14 22:53:23 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/14

CB-335D Vibratory Compactor D4E00001-UP (MACHINE) POWERED BY 3014 En... 1/3 Shutdown SIS Previous Screen Product: VIBRATORY COMPACTOR Model: CB-335D VIBRATORY COMPACTOR D4E Configuration: CB-335D Vibratory Compactor D4E00001-UP (MACHINE) POWERED BY 3014 Engine Disassembly and Assembly 3003, 3013, 3014 and 3024 Engines for Caterpillar Built Machines Media Number -SENR5027-05 Publication Date -01/05/2005 Date Updated -16/05/2005 i01783533 Fuel Filter Base - Disassemble SMCS - 1262-015 Disassembly Procedure Hand Priming Pump (if equipped) https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/14

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

CB-335D Vibratory Compactor D4E00001-UP (MACHINE) POWERED BY 3014 En... 2/3 Illustration 1 g00732631 Hand Priming Pump (1) Cap ring (2) Priming button (3) Diaphragm (4) Spring cap (5) Spring (6) Valve plate (7) O-ring seal (8) Fuel filter base 1. Unscrew cap ring (1) from fuel filter base (8). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/14

CB-335D Vibratory Compactor D4E00001-UP (MACHINE) POWERED BY 3014 En... 3/3 Personal injury can result from being struck by parts propelled by a released spring force. Make sure to wear all necessary protective equipment. Follow the recommended procedure and use all recommended tooling to release the spring force. 2. Remove priming button (2) and diaphragm (3) from spring cap (4). Inspect the rubber diaphragm (3) for cracks or for wear. If the diaphragm is worn or damaged, use a new part for replacement. 3. Remove spring cap (4) and spring (5) from valve plate (6) . 4. Remove valve plate (6) from fuel filter base (8). Copyright 1993 - 2021 Caterpillar Inc. Sat Aug 14 22:54:18 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/14

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com