Understanding SPC Charts for Performance Analysis

This integrated performance report provides a detailed explanation of Statistical Process Control (SPC) charts, highlighting variations, assurance levels, and key indicators. Learn how to interpret common causes, special causes, and the impact on meeting targets. The included icon descriptions help in identifying concerning trends and system capabilities, ensuring a reliable approach to hitting performance targets.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Integrated Performance Report A note on SPC charts 1

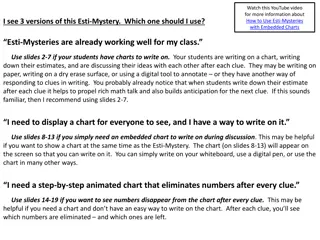

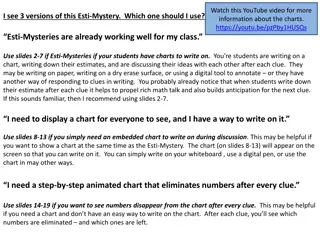

A note on SPC charts Variation Assurance Common cause no significant change Special cause of concerning nature or higher pressure due to (H)igher or (L)ower values Special cause of improving nature or lower pressure due to (H)igher or (L)ower values Variation indicates inconsistently passing and falling short of the target Variation indicates consistently (P)assing the target Variation indicates consistently (F)alling short of the target 2

High Level Key - Variation Are we improving declining or staying the same Orange = significant concern or high pressure Grey no significant change Blue = significant improvement or low pressure 3

High Level Key - Assurance Can we reliably hit the target Orange = system change required to hit target Blue = will reliably hit the target Hit and miss the target 4

Summary Icon Descriptions Description Perform Assure Special cause of a concerning nature where the measure is significantly HIGHER. This occurs where there is higher pressure in the system or deteriorating performance. This system is not capable. It will FAIL the target without system change. Special cause of a concerning nature where the measure is significantly HIGHER. This occurs where there is higher pressure in the system or worse performance. However despite deterioration the system is capable and will consistently PASS the target. Special cause of a concerning nature where the measure is significantly HIGHER. This occurs where there is higher pressure in the system or worse performance. This system will not consistently hit or miss the target. (This occurs when target lies between process limits). Special cause of a concerning nature where the measure is significantly LOWER. This occurs where there is deteriorating performance. This system is not capable. It will FAIL the target without system change. Special cause of a concerning nature where the measure is significantly LOWER. This occurs where there is deteriorating performance. However the system is capable and will consistently PASS the target. Special cause of a concerning nature where the measure is significantly LOWER. This system will not consistently hit or miss the target. (This occurs when target lies between process limits). Common cause variation, no significant change. This system is not reliably capable. It will FAIL to consistently meet target without system change. Common cause variation, no significant change. The system is capable and will consistently PASS the target. Common cause variation, no significant change. This system will not consistently hit or miss the target. (This occurs when target lies between process limits). 5

SPC rules Special Cause Variation A breach of the upper/lower control limit A run of ascending/descending data points 2 out of 3 points close to the control limit Variation indicating consistently failing the target target line above upper control limit Variation indicating consistently passing the target target line below lower control limit A run of points all one side of the mean

Further information For further information on SPC charts, please visit: Understanding Statistical Process Control charts, Skills Development Network. https://www.skillsdevelopmentnetwork.com/infoskills/assets/documents/IS/Understanding %20SPC%20Charts.pdf 7