EarTh.HOrizon Sensor Manufacturing Status Review at University of Colorado Aerospace Engineering Sciences

This comprehensive status review covers various aspects of the EarTh.HOrizon sensor manufacturing project at the University of Colorado Aerospace Engineering Sciences. The status of manufacturing, software development, electrical components, algorithms, mechanical aspects, and budget allocations are detailed through images and descriptions of different phases. The team members involved, customers, and advisor are also highlighted. Progress updates, schedule milestones, and levels of success criteria are outlined, indicating the project's successful advancement in areas like sensor capabilities, housing requirements, telemetry tests, and software functionality. Specific focus areas like sensor data collection, weight/volume requirements, power input/output, and communication protocols are addressed in the context of achieving project objectives.

- Sensor Manufacturing

- University of Colorado

- Aerospace Engineering

- Status Review

- Mechanical

- Electrical

Uploaded on Oct 08, 2024 | 0 Views

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

EarTh HOrizon Sensor Manufacturing Status Review Team Noah Buchanan Matthew Busby Matthew Cirbo Taylor Dean Jesse Keefer Patrick Klein Thomas Konnert Cole Oppliger Neal Stolz Customers Joe Breno Randy Owen Advisor Dr. John Farnsworth 1 University of Colorado Aerospace Engineering Sciences 10/8/2024

Outline Overview Schedule Manufacturing Software Electrical Algorithm Mechanical Budget Outline Schedule Manufacturing Budget 10/8/2024 University of Colorado Aerospace Engineering Sciences 2

CONOPS REFERENCE PITCH DEFLECTION ROLL DEFLECTION Outline Schedule Manufacturing Budget 3 University of Colorado Aerospace Engineering Sciences 10/8/2024

CONOPS Sensor Housing Camera Field of View Outline Schedule Manufacturing Budget 4 University of Colorado Aerospace Engineering Sciences 10/8/2024

FBD Outline Schedule Manufacturing Budget 5 University of Colorado Aerospace Engineering Sciences 10/8/2024

Levels of Success LEVEL TWO LEVEL THREE LEVEL FOUR LEVEL ONE POWER SENSOR CAPABLE OF COLLECTING DATA FROM SIMULATED EARTH AT ALTITUDE OF 250-750 KM HOUSING MEETS WEIGHT AND VOLUME REQUIREMENTS INTEGRATED IN BASIC HOUSING REQUIREMENTS MET. INPUT OF 22-34 V AND MAX DRAW OF 5 W SENSOR CAPTURES DATA AND RETURNS DISPLACEMENT VECTOR OUTSIDE OF ECLIPSE CAPABLE OF RECORDING 200 MINUTES OF HEALTH TELEMETRY TEST DEVELOPED TO PROVE ECLIPSE FUNCTIONALITY COMMUNICATION OVER CAN PROTOCOL AT <388 KBPS SOFTWARE CAPABLE OF DETERMINING DISPALCEMENT VECTOR TO WITHIN 0.5 DEGREES DISPLACEMENT VECTOR DETERMINED IN ECLIPSE REGION OF 35 MIN Outline Schedule Manufacturing Budget 6 University of Colorado Aerospace Engineering Sciences 10/8/2024

Schedule MSR SPRING BREAK Financial Algorithm Test Mechanical Electrical Software Uncertainty Outline Schedule Manufacturing Budget 7 University of Colorado Aerospace Engineering Sciences 10/8/2024

Schedule MSR SPRING BREAK Financial Algorithm Test Mechanical Electrical Software Uncertainty Mechanical Manufacturing Slightly ahead of schedule 50% complete Planned finish date: 27 FEB 8 University of Colorado Aerospace Engineering Sciences 10/8/2024

Schedule MSR SPRING BREAK Powerboard Manufacturing Behind original schedule 60% complete Planned finish date: 27 FEB Health Sensor Code Planned finish date: 15 FEB Financial Algorithm Test Mechanical Electrical Software Uncertainty Physical Camera Interface Board designed/ordered Planned finish date: 20 FEB 9 University of Colorado Aerospace Engineering Sciences 10/8/2024

Schedule MSR SPRING BREAK 1 MAR Financial Algorithm Test Mechanical Electrical Software Uncertainty Camera Interface Software Slightly behind schedule 50 % Complete CAN Communications Code Begin 3 Feb Algorithm Production 100% complete Will require minor adjustments 10 University of Colorado Aerospace Engineering Sciences 10/8/2024

Schedule MSR SPRING BREAK 1 MAR Software/Algorithm Integration Passing variables and memory locations Memory allocation Timing adjustments and troubleshooting Financial Algorithm Test Mechanical Electrical Software Uncertainty Analog Video to USB connection Existing COTS parts Team experience with USB data transfer Visual camera via USB 12 March 11 University of Colorado Aerospace Engineering Sciences 10/8/2024

Schedule MSR SPRING BREAK 15 APR 1 MAR Financial Algorithm Test Mechanical Electrical Software Uncertainty Full System Testing 12 University of Colorado Aerospace Engineering Sciences 10/8/2024

Software Outline Schedule Manufacturing Budget 13 University of Colorado Aerospace Engineering Sciences 10/8/2024

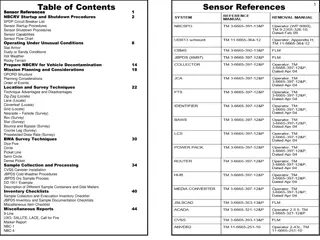

Software Data Flow 1. The IR sensor captures a frame and begins outputting to the DIO pins on the BeagleBone Black. 2. PRU0 acts as a software interface, and saves the data to a buffer in RAM. 3. Once an entire frame has been stored in RAM, the CPU is prompted to begin calculating the displacement vector. 4. After the displacement vector has been calculated, it is saved to an SD card with a time stamp and flag. Outline Schedule Manufacturing Budget 14 University of Colorado Aerospace Engineering Sciences 2/2/2015

Software: Status & Future Work Projected Completion Date Task Testing Enable PRU & load code Write & test code with LED Feb 1st Load drivers to enable DDR access for PRU Save data to RAM, access from CPU Feb 8th Control LED based on CPU interrupt from PRU pin Interrupt CPU from PRU Feb 15th Configure and receive data from IR camera Correctly display images from IR camera on CPU Feb 25th Trigger horizon algorithm using PRU data Mar 20th Outline Schedule Manufacturing Budget 15 University of Colorado Aerospace Engineering Sciences 2/2/2015

Software: Timing Diagram PRU Initialization Wait for first falling edge Save data to RAM Skip chroma byte Data is pulled from data lines 0 1 2 3 Outline Schedule Manufacturing Budget 10/8/2024 16 University of Colorado Aerospace Engineering Sciences

Software: Risk Mitigations Risk Mitigations Add instruction delay instead of waiting for falling edge 8-bit double-clocked YCbYCr 4:2:2 (45.73 ns) is too fast Mask data on CPU Try 14-bit or 16-bit YCbCr CMOS mode 4:2:2 (95.062 ns) Outline Schedule Manufacturing Budget 17 University of Colorado Aerospace Engineering Sciences 2/2/2015

Electrical Outline Schedule Manufacturing Budget 18 University of Colorado Aerospace Engineering Sciences 10/8/2024

Electrical System: Status Requirements: DR.2.2.1 Monitor operating voltages and currents DR.3.5 Use less than 5 W DR.3.6 Accept 22 34 V - Must output 5 V for Tau 2 and BBB Tau 2 Camera Vin Voltage Regulator 22 34 V 5 V Vin Vout BBB GND Von Vin GPIO R 3.3 V C Outline Schedule Manufacturing Budget 19 University of Colorado Aerospace Engineering Sciences 10/8/2024

Electrical System: Status All parts have been purchased Built on breadboard Tested to take in 22 34 V and outputs a constant 5.06 V Power Board Issues Solution Implemented Yet? Add a capacitor that is charged via 3.3 V pin on BBB. This means the chip is always on Regulator chip needs Von (< 6 V) to let power through Yes Use BBB controlled relays to prevent unregulated voltages from hitting camera Switching Regulators do NOT regulate until there is a load on them No Purchased adjustable regulator chip instead of fixed output Use resistors in feedback loop to control output voltage Yes Outline Schedule Manufacturing Budget 20 University of Colorado Aerospace Engineering Sciences 10/8/2024

Electrical System: Future Work Major Remaining Tasks Integrate voltage/current sensors into circuit Solder components onto a proto-board Test for voltage transients upon initial power on If no transients, relays may not be necessary Planned completion 27 Feb Outline Schedule Manufacturing Budget 21 University of Colorado Aerospace Engineering Sciences 10/8/2024

Algorithm Outline Schedule Manufacturing Budget 22 University of Colorado Aerospace Engineering Sciences 10/8/2024

Algorithm Purpose: To receive and process images from the camera and output pitch and roll displacement angles. Major Requirements: DR.2.1.1 Displacement outputs must be accurate to withing 0.5 . DR.2.1.2 Displacement in pitch and roll must be determined. DR.2.1.3 Displacement angles must be calculated at a rate of 12 Hz. Outline Schedule Manufacturing Budget 23 University of Colorado Aerospace Engineering Sciences 10/8/2024

Algorithm: Status All major functions needed for attitude determination have been written and tested on the BeagleBone Black. Algorithm requirements are being met. Max Error [deg] Max Corrected Error [deg] Mean Error [deg] Mean Corrected Error [deg] Roll 0.8606 0.1256 0.1825 0.0257 Pitch 1.9207 0.0688 1.1090 0.0265 Requirements Current Status DR.2.1.1 Accurate to within 0.5 degrees Successful: Max error = 0.1256 degrees DR.2.1.2 Determine displacement in pitch and roll Successful DR.2.1.3 Calculate displacement with a rate of >= 12 Hz Successful: Average rate = 400 Hz Outline Schedule Manufacturing Budget 24 University of Colorado Aerospace Engineering Sciences 10/8/2024

Algorithm: Future Work Major Remaining Tasks: Manually read image from memory locations Add assertions to check for anomalous conditions Outline Schedule Manufacturing Budget 25 University of Colorado Aerospace Engineering Sciences 10/8/2024

Mechanical System Outline Schedule Manufacturing Budget 26 10/8/2024 University of Colorado Aerospace Engineering Sciences

Mechanical Outline Schedule Manufacturing Budget 27 University of Colorado Aerospace Engineering Sciences 10/8/2024

Mechanical: Design Solution Power Regulator Board BeagleBone Black Housing Machined out of Aluminum 6061 Dimensions: 4.21 x 3.74 x 2.48 Camera mount redesigned to allow access to back of camera Test Stand: Custom 2 DOF Gimbal Machined out of Aluminum 6061 No major design changes Camera 4.21 Camera Mount Outline Schedule Manufacturing Budget 28 10/8/2024 University of Colorado Aerospace Engineering Sciences

Mechanical: Status Housing Purchased: Metal Manufactured: Top, Bottom, Left, and Right pieces. Mounting holes to be drilled. Top Test Stand Purchased: Thin-Section ball bearing and pitch ball bearings Manufactured: Roll Bracket Critical Element: Interference fit with thin-section ball bearing Bottom Left Right Outline Schedule Manufacturing Budget 29 University of Colorado Aerospace Engineering Sciences 10/8/2024

Roll Bracket (Picture) Machined on CNC mill to 0.0004 tolerance Initial machining attempt unsuccessful Allows sensor housing to roll Outline Schedule Manufacturing Budget 30 10/8/2024 University of Colorado Aerospace Engineering Sciences

Mechanical: Future Work Housing: Purchase: Metal for camera mount & screws Lead time: 1 week Setback: None, already 1 week ahead of schedule Manufacturing: CNC Final 3 pieces Front, Back, & Camera Mount Mount camera to within 1/32 in vertical direction Test Stand: Purchase: L brackets and bolts Lead time: 1 week Setback: none, planned into schedule Manufacturing: CNC face mount for sensor housing to 0.0004 tol Manual milling machines for remaining pieces Measure assembled housing height to 1/32 and manufacture disk for calculated radius Earth Disk manufactured Planned finish 27 Feb 2.23 Power Regulator Board BeagleBone Black Camera 4.21 Camera Mount Outline Schedule Manufacturing Budget 31 10/8/2024 University of Colorado Aerospace Engineering Sciences

Budget Status Future Expenses $885 Sensor and Housing, $2,125.84 Margin, $1,985.00 Testing Materials, $626.54 Printing, $50.61 Electronics, $212.01 Outline Schedule Manufacturing Budget 32 University of Colorado Aerospace Engineering Sciences 10/8/2024

Budget Progress $4,124.93 $3,230.92 $3,015.00 $215.92 Projected Total Expected Expenses for Parts Purchased Actual Expenses for Parts Purchased Budget Variance Outline Schedule Manufacturing Budget 33 University of Colorado Aerospace Engineering Sciences 10/8/2024

34 University of Colorado Aerospace Engineering Sciences 10/8/2024

Backup Slides This page intentionally left blank University of Colorado Aerospace Engineering Sciences 35 10/8/2024

Upcoming Testing Power Regulation Board (DR.3.6) Ensure 22-34V can be input and converted into two 5V outputs 5V Sensor Power Regulation Board Algorithm (DR.2.1) Verify algorithm functionality, speed, and accuracy meets requirements 22-34V Microcomputer 5V Power Regulation Board CONOPs Inclinometer Verify the functionality and calibrate for use in manufacturing, camera/BBB, and full tests Inclinometer Boresight Manufacturing (DR.3.3) Verify the dimensions of manufactured components as well as the initial focal point of the test stand on the disk Focal Point Height Horizon Disk Radius Inclinometer and Manufacturing CONOPs University of Colorado Aerospace Engineering Sciences 36 10/8/2024

Voltage Regulator Testing 37 University of Colorado Aerospace Engineering Sciences 10/8/2024

Ringing in Camera Lines Problem: Due to impedance differences between the camera and the BBB, ringing in lines may occur Testing for Problem: Connect BBB and camera and probe with o-scope Mitigating the Problem: -Keeping the lines short -Digital Line Drivers -Series resistors in lines to match impedances 38 University of Colorado Aerospace Engineering Sciences 10/8/2024

Power Board with Relays 39 University of Colorado Aerospace Engineering Sciences 10/8/2024

Algorithm Settings Algorithm settings are stored in shell environment variables Environment variables are loaded into globals to reduce the frequency of memory allocation to increase execution speed University of Colorado Aerospace Engineering Sciences 40 10/8/2024

Software: Assembly Code Outline Schedule Manufacturing Budget 41 University of Colorado Aerospace Engineering Sciences 2/2/2015

All Test Plans Power Regulation Board Ensure 22-34V can be input and converted into two 5V outputs Algorithm Verify algorithm functionality, speed, and accuracy Software Verify BeagleBone correctly computes algorithm and uses specified components, communication with camera, health data, and CAN functionality Inclinometer Verify the functionality and calibrate for use in manufacturing, camera/BBB, and full tests Manufacturing Verify the dimensions and weight of manufactured components as well as the initial focal point of the test stand on the disk Camera/BBB Verify the reception and saving of camera data via the BBB, the functionality of the algorithm on the BBB Full Test Validate the functionality of all aspects of the project as an integrated unit and determine what level of success is met University of Colorado Aerospace Engineering Sciences 42 10/8/2024

Power Regulation Board Test Purpose: Ensure the Power Regulation Board takes an input of 22- 34V and outputs 5V for both the camera and microcomputer. The Board should output 5V regardless of input voltage. Materials: Power Supply from Trudy s lab Any lab with proper outlet Voltmeter Completed Power Regulation Board or prototype Measurement How it s Verified Requirement Supply Output Voltmeter measured to be between 22-34V DR.3.6 PRB Outputs Voltmeter measured to be 5V DR.3.6 University of Colorado Aerospace Engineering Sciences 43 10/8/2024

Algorithm Test Purpose: To verify the algorithm produces a reasonably accurate output less than .5 at a rate between 12 and 30 Hz. To ensure its functionality prior to larger scale testing. Resources Needed: BeagleBone Black microcomputer loaded with algorithm Other computer for microcomputer output Group members to critique code Measurement How it s Measured Requirement Pitch/Roll Angle Output Speed Image processing by the algorithm DR.2.1.2 Recorded after vector data is output DR.2.1.3 Error Calculated vector data is compared to actual vector DR.2.1.1 University of Colorado Aerospace Engineering Sciences 44 10/8/2024

Manufacturing Test Purpose: Verify the manufactured components of the project (test stand, Earth disk, and sensor enclosure) closely align to the calculated values. Calculate the error introduced by manufacturing. Materials: Sensor Enclosure Earth Disk Test Stand Level Inclinometer External Computer Tape Measure Measurement Enclosure Focal Point Height Disk Radius Experimental Expected Value 2.48 x 4.21 x 3.74 4.52 .0625 16 .11 ;9.07 .11 90 tan 1?????? How it s Verified Measured value compared to expected value Measured value compared to expected value Measured value compared to expected value Use for comparison to inclinometer angle for test stand error ??? ? (16 ) (9.07 ) 15.79 .14 26.52 .14 Compared to calculated angle, yields error Compared to calculated angle, yields error University of Colorado Aerospace Engineering Sciences 45 10/8/2024

Inclinometer Test Purpose: Verify the functionality and calibrate for use in manufacturing, camera/BBB, and full tests Materials: Inclinometer (ADIS16209) BeagleBone Black External Computer Assembled Test Stand Process: Connect inclinometer to BeagleBone Black Use written software to establish communication between inclinometer and BeagleBone Black Run software to collect inclinometer data Verify output is received by BBB with external computer Calibrate inclinometer for zero degrees of displacement at test stand horizontal perturbation University of Colorado Aerospace Engineering Sciences 46 10/8/2024

Test Stand Scaling Boresight Focal Point Height Horizon Disk Radius Altitude Scaled Horizon Radius Focal Point Height Alpha * Measured by inclinometer 250 km 16 0.30 4.52 0.09 15.79 750 km 9.07 0.11 4.52 0.09 26.52 47 University of Colorado Aerospace Engineering Sciences 10/8/2024 University of Colorado Aerospace Engineering Sciences

Height Measurement Focal Point Distance Relative to Rear Distance From Front of Sensor Housing Measure distance between front of sensor box and Horizon disk Total distance of disk to focal point < 1/16th University of Colorado Aerospace Engineering Sciences 48 University of Colorado Aerospace Engineering Sciences 10/8/2024

Error in Stand Height Change in Height Focal Point Height Bore Sight Nominal Focal Point Height | | = Angular Error Stand Height = 4.52 Focal point height must be known to 1/16 to keep total error below 0.5 Test Horizon Half-Disk Radius 49 University of Colorado Aerospace Engineering Sciences 10/8/2024

Error in Disk Radius Camera Focal Point Focal Point Height Error in Radius Test Horizon Half-Disk Radius Disk Radius = 16.00 for 250 km = 9.07 for 750 km is smaller than pixel resolution for both 250 and 750 km disks Manufacturing tolerance governed by pixel resolution 0.30 for 250 km 0.11 (a little less than 1/8 )for 750 km University of Colorado Aerospace Engineering Sciences 50 10/8/2024