Pipeline Diameter Determination Using EMDS Curve Analysis

EMDS (EMDS Damage Relative Distance Ratio) curve analysis is utilized for determining the inside/outside diameter of pipelines based on relative damage distance. Collar mass variations and sensor readings indicate damages, such as compromised casing collars and unreported casing patches behind tubing. The analysis detects changes in casing weight, integrity compromises, and possible corrosion rates. Images illustrate examples of detected damages and compromised collar integrity in pipe joints.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

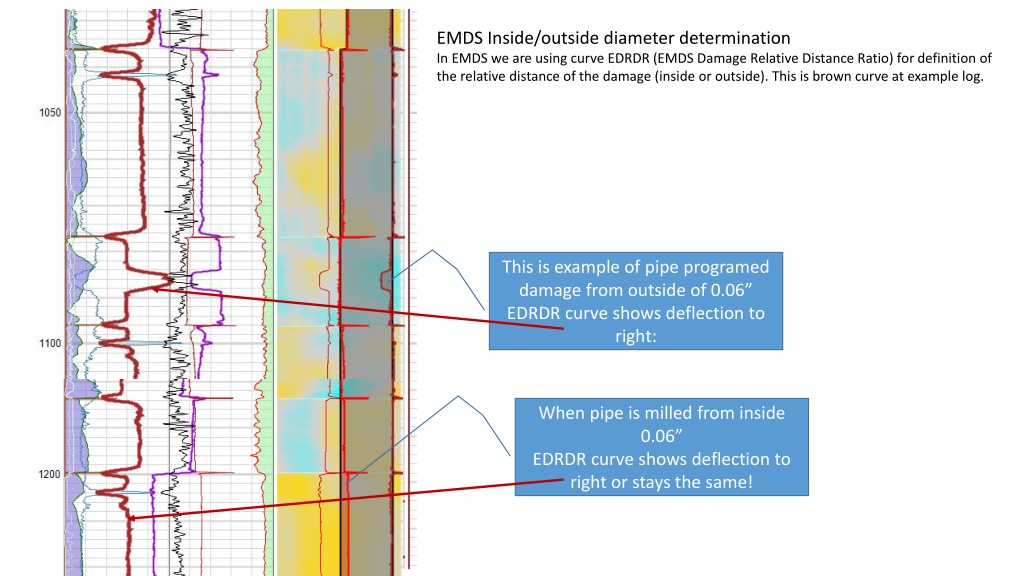

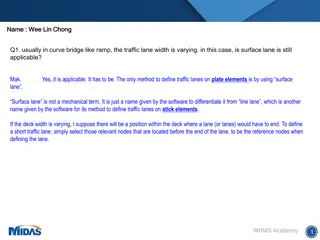

EMDS Inside/outside diameter determination In EMDS we are using curve EDRDR (EMDS Damage Relative Distance Ratio) for definition of the relative distance of the damage (inside or outside). This is brown curve at example log. This is example of pipe programed damage from outside of 0.06 EDRDR curve shows deflection to right: When pipe is milled from inside 0.06 EDRDR curve shows deflection to right or stays the same!

Typically collar shows lack of mass from inside(near channels red) and more mass from outside (far channels blue). Also red on B, BB Sensors while Blue at Far A and Far C sensors (can be red at near A and near C Sensors A Sensor B,BB,C, A A Sensor B Sensor BB Sensor C Sensor Typically addition of mass from outside (centralizer on casing) shows lack of mass from inside(near channels red) and more mass from outside (far channels blue) Typically damage from outside shows lack of mass from outside(far channels red) and more mass from inside (near channels blue)

100 EMDSA 10000 1.9 MFC 2.1 1 MFC 24 .23 EMDSNR 1.77 0 Time 142 0 Azimuth 702 0 Azimuth 432 0 Time 62 Second Pipe Third Pipe First Pipe

This is example unreported detected casing patch in the well behind tubing.

Unreported third casing of unknown size detected behind two pipes: tubing and casing.

Casing weight change detected behind tubing.

9326 Collar between joints 242 and 243 has compromised integrity and lack of mass in middle part. Maybe it was not screwed properly and was additionally damaged. Damage or corrosion rate in collar is hard to quantify! 7 bad collar. 7 good collar. Detection of bad casing collar behind tubing.

9544 Collar between joints 242 and 243 has compromised integrity and lack of mass in middle part. Maybe it was not screwed properly and was additionally damaged. Damage or corrosion rate in collar is hard to quantify! 7 bad collar. 7 good collar. Detection of bad casing collar behind tubing.

9714.8 Collar between joints 242 and 243 has compromised integrity and lack of mass in middle part. Maybe it was not screwed properly and was additionally damaged. Damage or corrosion rate in collar is hard to quantify! 7 bad collar. 7 good collar. Detection of bad casing collar behind tubing.