OACES Chip Seal Workshop Highlights and Insights

Delve into the world of chip seal production and oil rock operations with Billy Scott and Scott Ringham. Learn from their extensive experience at KRC, one of the top aggregate producers in the country. Discover the nuances of different candy bars and the reasons behind their production variations. Uncover the key factors affecting the cost of chip seal materials, including short notice challenges and market conditions.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

OACES Chip Seal Workshop OACES Chip Seal Workshop Oil Rock Production Presented by : Billy Scott & Scott Ringham

Billy Scott Billy Scott -14 Years with KRC -Background Duties- HE/CR/TR/AC/SA -WV Aggregate Sales & Customer Service Rep.

Scott Ringham Scott Ringham -16 Years with KRC -Background Duties- HE/CR/PR -WV Materials Production Superintendent

Top Ten Biggest Top Ten Biggest Agg -American Owned & Operated -Reside in 14 States, operate out of 19 -Oregon KRC Operations previously owned by: MBI or MORSE BROS -Growth Mode: Molalla/Viesko/Teevin Bros -Peak season about 300 employees in the WV -2.5+ Million Tons Per Year in WV!!! Agg Producer in the Country Producer in the Country

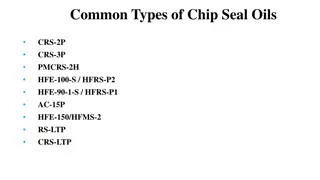

Candy Bars: Candy Bars: -Hershey s Chocolate Bar (3 -0) -Snicker s Chocolate Bar (3/4 -0) -Ghirardelli Chocolate s (Chip Rock) Why???

Candy Bars: WHY??? Candy Bars: WHY??? 3 - 0 is produced at higher rate per hour 3/4 - 0 is produced a little slower, more wear & tear, higher cost but most common

Candy Bars: WHY??? Candy Bars: WHY??? As is Ghirardelli chocolates, Chip Rock is a Specialty product with slow production, superior quality, weather sensitive, tight specs, higher cost, more down time. . . What else impacts the quality of this product? What else impacts the quality of this product?

What are the BIGGEST impacts that What are the BIGGEST impacts that raise the cost of Chip Seal Materials? raise the cost of Chip Seal Materials?

Chip Seal Increased Cost: Chip Seal Increased Cost: -Short Notice to crush = Higher cost -Screen Changes = Down time -Floor Loss 10-20% -Yard Balance -Market Conditions -Contamination -Lack of volume

What are the BIGGEST impacts that What are the BIGGEST impacts that lower the cost of Chip Seal Materials? lower the cost of Chip Seal Materials?

Chip Seal Cost Savings: Chip Seal Cost Savings: -Increase the spec range = Higher Production = $$$ -Plenty of Notice for planning (Staffing, dry weather, trucking, screens, delays) -Volume/Location/Crusher Moves -AC Plants or Bi-products - -1/2 1/2 - -1/4 order combined with 1/4 1/4 order combined with 1/4 - -#10??? - -Base Rock options??? Base Rock options??? #10???

What can you do to make a difference? What can you do to make a difference? -RFQ s around same time (Nov, not April) (More notice & earlier bidding) -Consistent Gradation Requirements or Specs (Bi-products & Crusher Moves = Higher Cost) -Multiple product balance???

Generally speaking, what products would Generally speaking, what products would typically be cheaper to produce from the chart? typically be cheaper to produce from the chart?

What are the most important factors to What are the most important factors to consider when bidding Chip Seal Materials? consider when bidding Chip Seal Materials?

What questions do you have? What questions do you have?

OACES Chip Seal Workshop OACES Chip Seal Workshop Oil Rock Production Presented by : Billy Scott & Scott Ringham