Comparing UV vs Traditional Printing

Deciding between UV and traditional flatbed printing really comes down to figuring out your project's specific needs. For speedy turnaround times, UV printing's instant cure is ideal (often making it a u2018best selleru2019, per se).

Download Presentation

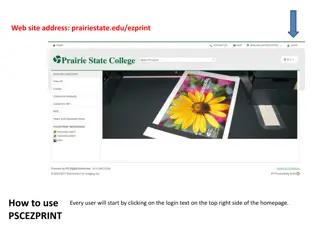

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

UV VS. TRADITIONAL

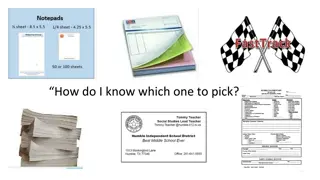

COMMON TYPES OF FLATBED PRINTING INKS

FEATURES OF UV FLATBED PRINTING