Understanding Synthetic Lubricants: Components and Manufacturing Process

Synthetic lubricants are formulated from small molecules to meet specific performance requirements. They offer advantages over mineral oils due to their tailored molecular structures. Components such as paraffins, iso-paraffins, naphthenes, and aromatics influence properties like pour point, traction, and volatility. Synthetic base stocks, including hydrocarbons and non-hydrocarbons, are used to create synthetic lubricants like polyalphaolefins (PAO) with high VI and oxidation stability. The manufacturing process involves polymerization and hydrogenation of hydrocarbons to produce high-quality lubricants sourced from crude oil.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

(6) Synthetic lubricants -- Synthesized oils from small building-block molecules to match molecular structures to performance requirements of the system

Mineral Oils - Natures Synthesis Cyclic/Aromatic Paraffinic Low cost Big mixture Mineral Oil Mineral oil refining removes many of the least desirable components (e.g. aromatics, waxes) and modifies the rest (e.g. hyrofinishing, hydrodewaxing and/or hydroprocessing)

Base Stock Component Properties Paraffins Iso-Paraffins Naphthenes Aromatics VI very high high medium/low lowest Pour point high low lower lowest Traction lowest low medium/high medium/high Volatility low low higher highest Solvency poor fair good excellent Oxidation Resistance good good lower resistance easily oxidized

Synthetic Base stocks Synthesized hydrocarbons Synthesized non-hydrocarbons (typically containing oxygen atoms)

Synthesized hydrocarbons Polyalphaolefins Polybutenes Alkylated aromatics Cycloaliphatics

Polyalphaolefins (PAO) Chain molecular structures synthesized from ethylene polymerization High VI and high oxidation stability Low pour point, low traction and volatility Best as engine oil basestock. Most popular PAO is polydecenes, which is the basestock of Mobil 1

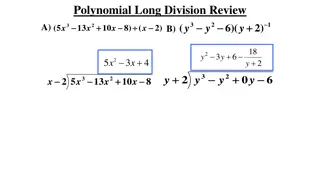

PAO Manufacture Polymerization Hydrogenation R - CH CH2 - CH H CH3 R - CH = CH2 x R Hydrogenated trimers, tetramers, etc. Alpha-olefins 1-Decene Polydecene Actual Ideal

Synthetic Polyalphaolefin (PAO) Hydrogenated Polydecene

From Crude Oil to Synthetic Lubricants Synthetics are usually sourced from crude oil Many manufacturing steps result in high cost Synthetic Lubricants Catalytic Crude Oil 1-Decene Polymerization Atmospheric Sales & Distillation Distillation Distillation Marketing Cracker Feed Alphaolefins Catalytic Catalytic Hydrogenation Blending Cracking Polymerization Light Olefins Ethylene Polydecene Separation Formulation Additives

Polybutenes Synthezied through controlled polymerization of butenes and isobutenes High dielectrics constant electrical insulating oils Low thermal stability metal working and compressor lubes to decompose to gases High molecular weight polybutenes or polyisobutenes are used as VI improvers

Alkylated aromatics Synthesized from alkylation of benzenes Very low pour point and low viscosity subzero temperature applications

Cycloaliphatics Synthesized naphthenes, multi-ring-structured molecules Develop a glasslike structure under high stresses to yield high traction Used as traction-drive fluids, also used in rolling bearings to reduce roller skidding

Synthesized non-hydrocarbons Organic esters Polyglycols Phosphate esters Silicate esters Polyphenyl esters

Organic esters Dibasic acid esters: Polyol esters: Wide temperature range and good thermal stability Used as base stocks for essentially all jet engine lubes

Polyglycols The largest single class of synthetic lubricant bases High VI and low pour point Used mainly as brake fluids and hydraulic fluids

Phosphate esters High fire resistance Used mainly as hydraulic fluids and compressor lubes Also used as antiwear additives by its formation of phosphide films on metal surfaces

Silicate ester Extremely high VI > 300 Used mainly as heat exchanger fluids

Polyphenyl esters Most thermally and oxidatively stable Used mainly as heat transfer fluids