Understanding Hybrid Thin Film Technology in Electronics

Hybrid thin film technology, spearheaded by Assistant Professor Somesh Kr. Malhotra, revolutionizes electronics with its superior circuit density and eco-friendly advantages. Thin film circuits, employing conductor, resistor, and dielectric layers, are thinner and more intricate than thick film circuits. Techniques like Low Pressure CVD offer precise control and fast deposition rates, leading to the conservation of materials and the creation of innovative products for diverse applications such as integrated circuits, CCDs, and LCDs.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Hybrid Thin film Technology Somesh Kr Malhotra Assistant Professor ECE Department,UIET

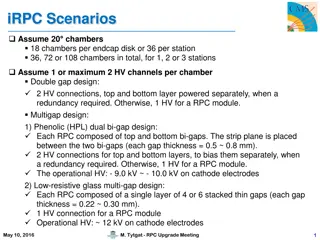

Introduction Thin film circuits consist of conductor layers, resistor layers and dielectric layers, similarly to thick film circuits. However, the thin film thicknesses are normally 1 m or less, an order of magnitude less than for thick film. Processes from silicon technology are used for deposition and definition of patterns. That gives higher circuit density than in thick film. The materials are also generally different.

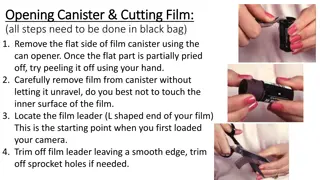

Atmospheric Pressure CVD In Atmospheric CVD, where the deposition reaction is carried out at atmospheric pressure in an open reactor.

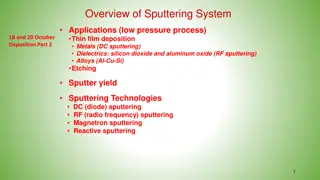

Low pressure CVD In Low pressure CVD, where the deposition reaction is carried out in an vaccum chamber. The advantage of low pressure CVD processes Uniform step coverage Precise control of composition and structure Low temperature processing Fast deposition rates High throughput Low processing cost.

Advantage of thin film Conservation of scarce materials, Production of nanostructured coatings and nanocomposites, Ecological considerations a reduction of effluent output and power consumption, Improved functionality of existing products, Solution to previously unsolved engineering problems and, Creation of entirely new and revolutionary products.

Application of Thin Film Passive thin film elements (Resistors, Condensers, Interconnects) Active thin film elements (Transistors, Diodes) Integrated Circuits (VLSI, Very Large Scale Integrated Circuit) CCD (Charge Coupled Device) LCD (Liquid Crystal Displays)