Understanding Overhead Allocation in Financial Accounting

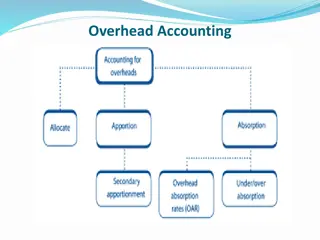

Overhead in accounting refers to expenses incurred in production or providing services that cannot be directly traced to specific products or departments. This involves classifying overhead based on function, element, and behavior, as well as allocating, apportioning, and absorbing overhead costs in cost centers. Various bases for apportionment such as rent, floor area, equipment costs, and personnel are used to distribute overhead among different cost centers effectively.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

THE INSTITUTE OF CHARTERED ACCOUNTANTS OF SRI LANKA POSTGRADUATE DIPLOMA IN BUSINESS AND FINANCE - 2015/2016 Principles of Financial and Cost Accounting Thilanka Warnakulasooriya B.Com Special, FCA, MBA-Fin

Accounting for Overhead Overhead is the Expenditure incurred in the course of making a product, providing a service or running a department, but which cannot be traced directly and fully to the product, service or department

Classification of Overhead Overhead can be classified under 3 basis Overhead Function Based Element Base Behavior based Production OH Indirect Material Fixed Overhead Administration OH Indirect Labor Variable OH Selling & Distribution OH Indirect Expense Semi-Variable OH General OH

Overhead Allocation, apportionment & absorption Steps. 1. Identify OH cost & Accumulate the cost i.e. Rent , Electricity, 2. Identify the Cost Center of the Organization Identify the activity or item or equipment where the cost are accumulated. Cost centers can be either production cost center or service cost center i.e Garment Factory Production cost centers Cutting, Sawing, washing, Packaging Service cost centers Maintenance , HRM, Planning

3. Allocation of OH cost to cost centers Some OH can be directly identify to a particular cost centers. Accordingly that OH cost can be allocated to that cost center called allocation i.e. Cutting supervisor salary directly identified to the cutting cost center 4. Some OH can not be directly identified to particular cost center. Accordingly such cost should be shared among the cost centers. These cost should be divided among cost centers based on most reasonable basis. Apportioning overhead cost to cost centers (Apportionment of overhead is distribution of overheads to more than one cost centre on some equitable basis)

OH Basis for Apportionment Rent, rates, heating and light, repairs and depreciation building Floor area occupied by each cost centre of Deprecation and insurance of equipment Cost or book value of equipment Personnel, welfare, wages and costs of offices office, canteen, Number of employees, or labor hours worked in each cost centre i.e. Garment factory monthly electricity bill was Rs. 200,000. Factory consist of 4 cost centers . The floor area occupied by each cost center are as follows. Cost Center Floor area (Sq. Feet) Cutting 3,000 Sawing 5,000 HR 500 Warehouse 1,500 Apportion the electricity between cost centers.

5. Reapportioning the service cost centre cost to production cost centers. Service cost centers cost should charged to production cost centers since salable units does not pass through service departments. The reasonable apportionment basis should be used Service cost centre Possible basis of apportionment Number of cost value of material requisitions Stores Maintenance Hours of maintenance work done for each cost centre Production planning Direct labor hours worked in each production cost centre

Reapportioning the service cost centre cost to production cost centers Secondary Distribution with reciprocal Servicing overhead absorption rates To production & service department Direct Method Simultaneous Equation Method Only to Production Department Repeated Distribution Method Step Down Method

6. Calculate the overhead absorption rate & absorb the cost Overhead absorption is the process whereby overhead costs allocated and apportioned to production cost centers are added to unit, job or Cost object. Overhead absorption is sometimes known as overhead recovery Overheads are usually added to costs units using a predetermined overhead absorption rate, which is calculated using figures from the budget. Overhead absorption rate (OAR) Attributing OH to particular product or service based on particular basis Generally OAR calculated by dividing the OH cost of the cost center by number of units/ Volume of absorption base which is appropriate for the cost center

Calculation of overhead absorption rate OAR = Budgeted Overhead cost Budgeted volume Estimate the overhead likely to be incurred during the period Estimate the activity level for the period Divide the estimated overhead by the budgeted activity level Absorb the overhead into the cost unit by applying the calculated absorption rate Ex 04 There is no ideal OAR, depending on the company some use machine hours or labor hours. The most appropriate OAR depends on factors such as cost, information availability, nature of the product, technology used etc.

Choosing absorption base A percentage of direct materials cost A percentage of direct labor cost A percentage of prime cost A rate per machine hour A rate per direct labor hour A rate per unit A percentage of factory cost (for admin overhead) A percentage of sales or factory cost ( for selling and distribution overhead) the appropriate 11

Over and under absorption of overheads The rate of overhead absorption is based on estimates ( of both numerator and denominator) and it is quite likely that either one or both of the estimates will nit agree with what actually occurs Over absorption means that the overheads charged to the cost of sales is more than the overheads actually incurred Under absorption means that insufficient overheads have been included in the cost of sales Actual Overhead incurred Overhead absorbed (budgeted OAR * actual activity level) xxxx xxxx Under/ Over absorption xxx 12

The reasons for over/under absorbed overheads The overhead absorption rate is predetermined from budget estimates of overhead cost and the expected volume of activity. Over or under recovery of overhead will occur in the following circumstances:- Actual overhead costs are different from budgeted overhead The actual activity level is different from the budgeted activity level Actual overhead costs and actual activity level differ from the budgeted costs and levels i.e . Following information with regard to A Company Budgeted overhead cost per month Actual Overhead cost per month Budgeted units plan to produce Actual units Produced 80,000 70,000 10,000 8,000 Calculate over or under absorption of overhead per month 13