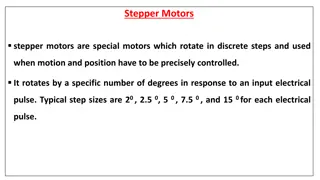

The Stepper Motor.

Stepper motors, known for their movement in steps, are essential in applications like printers, plotters, robotics, and more. This technology offers precise control over rotation angle, speed, and position, making it ideal for diverse industries. The construction and operation principles of stepper motors cater to the specific needs of equipment requiring accurate and reliable movement.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Lect.7 The Stepper Motor

This motor called stepper due to its behavior, that it moves in steps. This machine can be classified as a Reluctance Motor or sometimes as a Permanent Magnet Motor, and one of its types is the Hybrid Stepper Motor due to the mixing between the usage of cores of reluctance type and permanent magnet type in the construction of its rotor. Hence, there are three types of this motor: The Variable Reluctance type, The Permanent Magnet Type, and The Hybrid Type. But as it is well known that both of the PMM and RM can move in steps when their stator winding composed of salient poles and fed by DC voltage through electronic switches. So, what is new in this type of machines? The main idea of manufacturing this type of motor, is the load requirements in the following applications:

1. Printers. 2. Plotters. 3. High-end office equipments. 4. Hard disk drives. 5. Medical equipments. 6. Fax machines. 7. Automotive. 8. Robotics. 9. And many more. Now you have to think about the common requirements of these equipments! It is clear that they need a machine able to furnish the following: Ease to control rotation angle, speed, position and synchronism. A low power and low cost and small volume drives.

An open loop control drives. Accurate, precise, reliable and repeatability of movement drives. The above requirements lead to create the stepper motor. Hence, this motor is a new technology (but not a new idea) machine. It has special characteristics to be used in such applications. In order to study this machine, its construction and principle of operation must be studied.

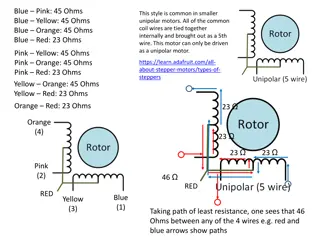

The Construction of Stepper Motor As it mentioned before that there are three types of this motor: Variable Reluctance (VR) Motor: It composed of a soft iron multi-toothed rotor and salient wound stator. When the stator windings are energized with DC current the poles become magnetized. Rotation occurs when the rotor teeth are attracted to the energized stator poles.

Permanent Magnet (PM) Motor: It is a low cost and low resolution type motor. Typical step angles of 7.5 to 15 . (48-24 steps/revolution). The rotor is magnetized alternating north and south poles situated in a straight line parallel to the rotor shaft. This structure provide an increased magnetic flux intensity and because of this the PM motor exhibits improved torque characteristics when compared with VR type. with