Inspection Machines Market Growth, Trends, Size, Revenue, Share, Challenges

Inspection Machines Market by Offering (Hardware, Software), Automation Mode (Automatic Inspection, Semi-automatic Inspection, Manual Inspection), End User (Pharmaceutical and Biotech, Food and Beverages), and Geography - Global Forecast to 2030

1 views • 3 slides

What Are SEMA Racking Inspection Guidelines?

SEMA racking inspection guidelines are the gold standard of the racking safety industry.\n\nWithout SEMA racking inspection guidelines, guaranteeing the safety of any warehouse would be impossible. The advice laid down by SEMA is often echoed by HSE and \u2014 in some cases \u2014 it becomes law. So

1 views • 2 slides

Do I need an inspection by a SEMA Approved Rack Inspector?

HSE recommends that British warehouses receive an annual racking inspection from a SEMA approved racking inspector. But what counts as a warehouse in HSE\u2019s eyes? Does your business need a an inspection by a SEMA Approved rack inspector?\n\n\/\/seerackinginspections.co.uk\/do-i-need-a-sema-appro

1 views • 3 slides

Racking Inspection Frequency & Cemetery Inspections

With so much health and safety law dependent on inspections, defining it legally can literally be a matter of life and death.\n\nAn enormous part of warehouse safety is racking inspection frequency, which HSE spells out in HSG76 \u2014 Warehousing and Storage: A Guide to Health and Safety.\n\n\/\/se

4 views • 3 slides

Permanent-Mold Die Casting Processes Overview

Permanent-mold die casting is a process where molten metal is injected into a mold cavity under high pressure, maintained during solidification. This process utilizes hot-chamber and cold-chamber die casting machines for casting various metals like zinc, aluminum, brass, and magnesium. Hot-chamber m

4 views • 7 slides

Understanding Patterns in Casting Process

Patterns play a crucial role in the casting process by creating replicas of objects with modifications, such as pattern allowances and core prints. They help in forming mold cavities, reducing casting defects, and minimizing costs. Various materials like wood, metal, and plastics are used for patter

1 views • 15 slides

EHSA System Inspection and Audit Guide

The EHSA System Inspection and Audit Guide provides detailed information on responding to inspection findings in EH&S lab safety audits. It includes instructions on accessing audit results, responding to findings, and navigating the Safety Inspections module within the EHSA system. The guide outline

1 views • 11 slides

inspection machine

The inspection machines market is witnessing strong growth, with key players actively investing in research and development to enhance their product offerings and market presence. Technological advancements in the industry include the integration of inspection systems such as weighing machines, meta

1 views • 4 slides

Overview of Casting Alloys: Ferrous and Nonferrous Options

Commercial castings are predominantly made from alloys rather than pure metals for better properties and casting ease. Ferrous casting alloys include cast iron and steel, each with unique characteristics and challenges. On the nonferrous side, aluminum, copper alloys, and zinc alloys offer various b

0 views • 15 slides

Understanding Solidification Process in Metal Casting

Solidification in metal casting involves nucleation and growth processes, impacting the final product's quality. Factors such as type of metal, thermal properties, and mold shape influence solidification. Homogeneous nucleation occurs below the equilibrium freezing point, while heterogeneous nucleat

1 views • 8 slides

Common Casting Defects in Prosthodontics: Causes and Prevention

Casting defects in prosthodontics can result from errors in the casting procedure, leading to issues like distortion, surface roughness, porosity, and incomplete detail. Various causes such as stress relaxation during wax pattern preparation can contribute to distortion, while factors like air bubbl

5 views • 27 slides

Metal Alloys Forming Operations: Forging, Casting, and More

Metal alloys undergo forming operations like forging, rolling, extrusion, and casting to change their shape through plastic deformation. Hot working and cold working processes are utilized to enhance mechanical properties. Techniques such as sand casting, die casting, and investment casting are empl

0 views • 18 slides

United States Food Safety and Inspection Service: Ensuring Meat and Poultry Products' Safety

The United States Department of Agriculture's Food Safety and Inspection Service (FSIS) oversees the federal inspection of meat and poultry products to ensure their safety for human consumption. The statutes governing this process include the Federal Meat Inspection Act, the Poultry Products Inspect

0 views • 23 slides

Quality Assurance and Inspection Processes in Manufacturing

Quality assurance and inspection play a crucial role in ensuring products meet standards. Inspection is categorized into receiving, in-process, and final stages. Standards of measurement, interchangeability, and factors influencing quality are discussed, along with planning and types of inspection.

0 views • 44 slides

Understanding Casting Defects in Metal Casting Processes

A casting defect is an undesirable irregularity in metal casting processes that may require correction or elimination. This article discusses the definition, types, remedies, causes, prevention, and conclusion of casting defects. It covers shrinkage defects, gas porosity, pouring metal defects, meta

0 views • 21 slides

Investment Casting Process: A Detailed Step-by-Step Guide

Investment casting process involves creating a wax pattern, assembling the pattern onto a sprue, coating with ceramic layers, de-waxing and firing, casting molten metal, knockout, finishing, testing, inspection, packing, and shipping. This detailed guide provides insights into each step of the inves

0 views • 10 slides

Tips for Preparing for an OHCS Inspection

When preparing for an OHCS inspection, property managers should conduct a thorough inspection of the site, building exteriors, systems, and common areas. All residents must be informed, and all inspectable items should function properly. Compliance with inspection protocols is crucial to ensure a sm

0 views • 27 slides

A New Approach to TLS Inspection

This article explores a new approach called IA2-TLS for inspecting Transport Layer Security (TLS) anytime and anywhere. It discusses the primary goals of TLS, the increasing importance of data encryption over networks, and the need for TLS inspection to enhance security controls. The challenges of i

1 views • 46 slides

ASEAN Guidelines on GMP for Traditional Medicines/Health Supplements - Preparation for Inspection

This content provides guidelines on preparing for a Good Manufacturing Practice (GMP) inspection for traditional medicines and health supplements in ASEAN countries. It covers activities such as planning inspections, forming inspection teams, reviewing documentation, preparing inspection plans, hold

0 views • 19 slides

Vehicle Inspection and Registration System Overview

This information highlights the changes in vehicle inspection and registration processes, particularly focusing on the transition to a registration-based enforcement system starting March 1, 2015. It explains the importance of the Vehicle Inspection Report (VIR) and how the new system affects regist

0 views • 21 slides

Pre-Inspection Briefing Guidelines for OCPF Regime

The Pre-Inspection Briefing (PIB) is a crucial initial activity during Chemical Weapons Convention inspections, aiming to establish a cooperative atmosphere. This guideline outlines the requirements for PIB at industrial facilities under CWC Article VI inspections, helping the Inspected State Party

0 views • 17 slides

Understanding OSHA Inspection Process: Safety Training Overview

This presentation, created by the N.C. Department of Labor, delves into the OSHA inspection process. It covers various inspection types, procedures, rights and responsibilities of employers and employees, and post-inspection processes. Key topics include amputations, inspection priorities, special e

0 views • 23 slides

Understanding Ray Tracing Techniques in Computer Graphics

Explore the fundamentals of ray tracing including recursive ray casting, ray casting vs. ray tracing, basic algorithms, shadows, reflections, refractions, and advanced illumination models like Whitted model and OpenGL's illumination model. Learn about casting rays from the eye, handling reflections

0 views • 50 slides

Supplier Briefing Pack for Inspection Processes

Inspection processes are crucial steps in ensuring product quality and compliance with specifications. This briefing pack covers general requirements, visual inspection, dimensional inspection, non-destructive testing, calibration, control and measuring equipment, and inspection records. Emphasis is

0 views • 10 slides

Pre-Inspection Briefing Guidelines for Chemical Weapons Convention (CWC) Inspections

The Pre-Inspection Briefing (PIB) is a crucial activity for facilities undergoing CWC inspections, helping the Inspection Team fulfill their mandate efficiently. This guideline outlines the requirements for conducting a PIB, including operational activities, safety measures, logistics, and confident

0 views • 17 slides

Guidelines for Pre-Inspection Briefing in Chemical Weapons Convention

The Pre-Inspection Briefing (PIB) is a crucial initial activity in Chemical Weapons Convention (CWC) inspections, aimed at creating a cooperative atmosphere. This guideline outlines essential requirements for the PIB, including operational activities, safety measures, logistics, confidentiality, and

0 views • 18 slides

Inspection Profiles of Largest Children's Homes Providers - August 2018

Explore the inspection profiles of the largest private and voluntary providers of children's homes as of August 2018. Gain insights into ownership and inspection outcomes of over 500 homes, highlighting key organizations and national comparisons. Dive into the varying inspection profiles and outcome

0 views • 5 slides

Understanding OHCS Inspection Rating Process at AHMA Conference Summer 2019

Learn about the OHCS inspection rating process discussed at the AHMA Conference Summer 2019. The process includes different types of inspections, steps involved in the inspection process, common findings, tips to improve rating, consequences of non-compliance, and the new IRS requirements. Understan

0 views • 21 slides

Understanding Ofsted Inspection and Quality Assurance in Further Education & Skills

Ofsted inspects and assures the quality of apprenticeship provision, specifically at level 4 and/or 5 with a recognized HE award. Providers offering apprenticeship training at these levels are within Ofsted's scope for inspection. The inspection process includes feedback, published reports, monitori

0 views • 14 slides

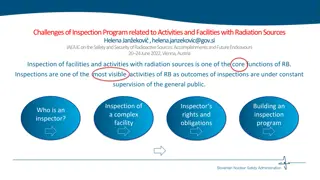

Challenges of Inspection Program Related to Radiation Sources Facilities

Inspection of facilities and activities with radiation sources presents challenges related to inspector qualifications, complex facility inspection, and inspector rights and obligations. Specific issues include the lack of standardized education for radiation safety inspectors, handling complex or f

0 views • 9 slides

Component Design Basis Inspection (CDBI) Program Overview

The Component Design Basis Inspection (CDBI) program ensures plant components are maintained within their design basis and monitors their capability to perform essential functions. Insights reveal the inspection frequency, estimated hours, fees, team composition, and inspection schedule. The baselin

0 views • 18 slides

Improving Real Estate Assessment Center (REAC) Inspections: National Standards for the Physical Inspection of Real Estate (NSPIRE) Overview

The National Standards for the Physical Inspection of Real Estate (NSPIRE) aims to address the shortcomings in current inspection models for HUD and HUD-assisted properties. The Inspection Task Force is reexamining REAC inspections to focus on health and safety hazards, year-round maintenance practi

0 views • 19 slides

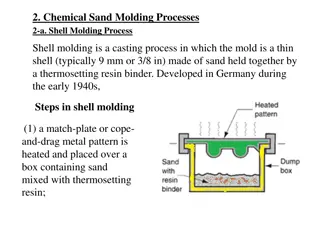

Overview of Shell and Sodium Silicate Molding Processes in Casting

Shell molding is a casting process involving a thin sand shell held together by a resin binder, offering advantages like smoother mold cavity surfaces and good dimensional accuracy. However, it can be costly for small quantities. Sodium Silicate Molding Process involves coating refractory materials

0 views • 19 slides

Level II Inspection Overview

Level II inspection involves specialized knowledge and equipment for detailed assessments of bridge components. It includes various inspection types like CSE testing, concrete deck inspection, underwater inspection, and more. The process follows specific forms for bridges and culverts, emphasizing t

0 views • 19 slides

ASEAN Guidelines on GMP for Traditional Medicines - Preparation for Inspection

This content outlines the preparation activities for a Good Manufacturing Practice (GMP) inspection for Traditional Medicines/Health Supplements as specified by the ASEAN Guidelines. It covers the objectives, processes, inspection team formation, documentation review, and other key aspects involved

0 views • 19 slides

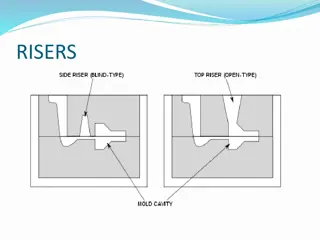

Understanding Risers and Casting Defects in Metal Casting Process

Risers are crucial in reducing shrinkage problems during casting by promoting directional solidification. Open versus blind risers have distinct characteristics affecting feeding and positioning within the mold. Rapid cooling rate and use of insulating compounds impact the efficiency of casting, whi

0 views • 41 slides

Post Inspection Binder and Reports Overview

This document contains a comprehensive overview of the post-inspection processes and requirements, including details on the inspection binder, copies of the last inspection reports, adoption of by-laws, post incorporation, officer positions filing, delegate selection, maintenance of books and record

0 views • 31 slides

Understanding Aluminium Sand Casting Process

Aluminium sand casting is a cost-effective process commonly used in schools due to its affordability and achievable casting temperature. The process involves pattern making, moulding, pouring molten metal, removing sand, and cleaning the final workpiece. Quality patterns and moulds are crucial for s

0 views • 10 slides

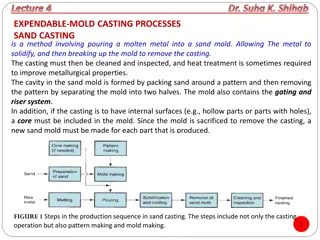

Expendable-Mold Casting Processes in Sand Casting: Lecture Insights

Sand casting is a process wherein molten metal is poured into a sand mold, left to solidify, and then the mold is broken to retrieve the casting. This casting method involves pattern making, mold creation, and uses a gating and riser system for complex geometries. Riser design is crucial in managing

0 views • 9 slides

Overview of Metal and Sand Casting Processes

Metal and sand casting are ancient manufacturing techniques dating back to 4000 B.C., allowing the production of complex shapes in various metals. The casting industry produces millions of kilograms of castings annually, primarily using materials like gray iron, ductile iron, aluminum alloys, and co

0 views • 13 slides