Overview of Shell and Sodium Silicate Molding Processes in Casting

Shell molding is a casting process involving a thin sand shell held together by a resin binder, offering advantages like smoother mold cavity surfaces and good dimensional accuracy. However, it can be costly for small quantities. Sodium Silicate Molding Process involves coating refractory materials with a sodium-silicate-based binder. Both processes have their unique applications and benefits in the casting industry.

Uploaded on Oct 01, 2024 | 0 Views

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

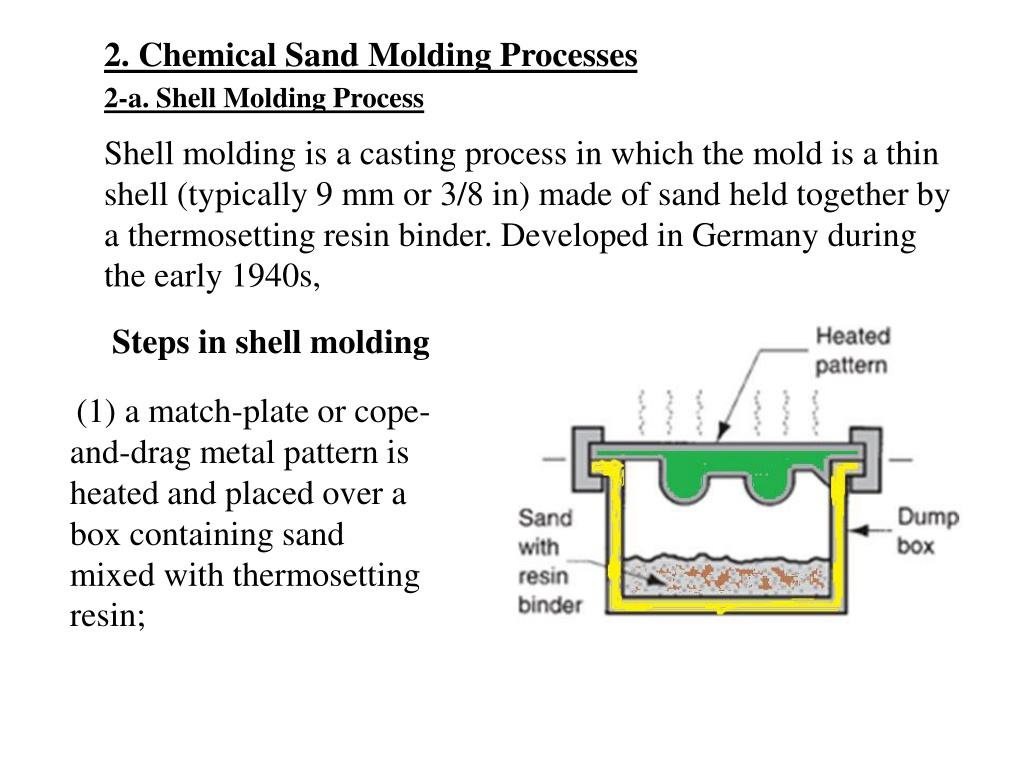

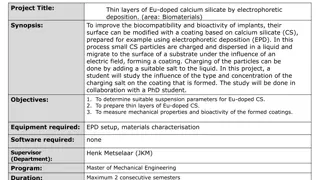

2. Chemical Sand Molding Processes 2-a. Shell Molding Process Shell molding is a casting process in which the mold is a thin shell (typically 9 mm or 3/8 in) made of sand held together by a thermosetting resin binder. Developed in Germany during the early 1940s, Steps in shell molding (1) a match-plate or cope- and-drag metal pattern is heated and placed over a box containing sand mixed with thermosetting resin;

(2) box is inverted so that sand and resin fall onto the hot pattern, causing a layer of the mixture to partially cure on the surface to form a hard shell; (3) box is repositioned so that loose, uncured particles drop away;

(4) sand shell is heated in oven for several minutes to complete curing; (5) shell mold is stripped from the pattern;

(6) two halves of the shell mold are assembled, supported by sand or metal shot in a box, and pouring is accomplished. (7) The finished casting with sprue removed is shown in.

There are many advantages to the shell-molding process. The surface of the shell mold cavity is smoother than a conventional green-sand mold, and this smoothness permits easier flow of molten metal during pouring and better surface finish on the final casting. Finishes of 2.5 m (100 -in) can be obtained. Good dimensional accuracy is also achieved, with tolerances of 0.25 mm ( 0.010 in) possible on small-to- medium-sized parts. The good finish and accuracy often precludes the need for further machining. Collapsibility of the mold is generally sufficient to avoid tearing and cracking of the casting.

Disadvantages of shell molding include a more expensive metal pattern than the corresponding pattern for green-sand molding. This makes shell molding difficult to justify for small quantities of parts. Shell molding can be mechanized for mass production and is very economical for large quantities. It seems particularly suited to steel castings of less than 20 lb. Examples of parts made using shell molding include gears, valve bodies, bushings, and camshafts.

2-b. Sodium Silicate Molding Process In this process, the refractory material is coated with a sodium silicate-based binder. For molds, the sand mixture can be compacted manually, jolted or squeezed around the pattern in the flask. After compaction, CO 2 gas is passed through the core or mold. The CO2 chemically reacts with the sodium silicate to cure, or harden, the binder. This cured binder then holds the refractory in place around the pattern. After curing, the pattern is withdrawn from the mold.

The sodium silicate process is one of the most environmentally acceptable of the chemical processes available. The major disadvantage of the process is that the binder is very hygroscopic and readily absorbs water, which causes a porosity in the castings.. Also, because the binder creates such a hard, rigid mold wall, shake out and collapsibility characteristics can slow down production. Some of the advantages of the process are: A hard, rigid core and mold are typical of the process, which gives the casting good dimensional tolerances; good casting surface finishes are readily obtainable;

3-Permanent Mold Process In all the above processes, a mold need to be prepared for each of the casting produced. For large-scale production, making a mold, for every casting to be produced, may be difficult and expensive. Therefore, a permanent mold, called the die may be made from which a large number of castings can be produced. , the molds are usually made of cast iron or steel, although graphite, copper and aluminum have been used as mold materials. The process in which we use a die to make the castings is called permanent mold casting or gravity die casting, since the metal enters the mold under gravity. Some time in die-casting we inject the molten metal with a high pressure. When we apply pressure in injecting the metal it is called pressure die casting process.

Steps in permanent-mold casting : (1) mold is preheated and coated;

(2) cores (if used) are inserted, and mold is closed (3) molten metal is poured into the mold

(4) mold is opened (5) Finished part is shown

Low-pressure casting. The diagram shows how air pressure is used to force the molten metal in the ladle up ward in to the mold cavity. Pressure is maintained until the casting has solidified.

Cycle in hot- chamber casting (1) with die closed and plunger withdrawn, molten metal flows into the chamber

(3) plunger is withdrawn, die is opened, and solidified part is ejected. (4) Finished part is shown

Cycle in cold-chamber casting : (1) with die closed and ram withdrawn, molten metal is poured into the chamber (2) ram forces metal to flow into die, maintaining pressure during cooling and solidification

(3) ram is withdrawn, die is opened, and part is ejected. (Gating system is simplified.)

Advantages Permanent Molding produces a sound dense casting with superior mechanical properties. The castings produced are quite uniform in shape have a higher degree of dimensional accuracy than castings produced in sand The permanent mold process is also capable of producing a consistent quality of finish on castings

Disadvantages The cost of tooling is usually higher than for sand castings The process is generally limited to the production of small castings of simple exterior design, although complex castings such as aluminum engine blocks and heads are now commonplace