YONEX Nanoray 6000I G4-U Aluminum Badminton Racquet With Full Free Shipping

Precision in Play: YONEX Nanoray 6000I Badminton Racquet\n\nUnleash the power of precision on the badminton court with the Nanoray 6000I. Crafted with cutting-edge technology and featuring an aluminium frame, this racquet offers exceptional control and manoeuvrability. Whether you're a seasoned play

0 views • 3 slides

FSAE Electric Powertrain Design

In-depth overview of the FSAE electric powertrain design featuring battery cooling, arrangement, connectors, accumulator setup, and cooling system. The design includes Samsung 18650 batteries, premade Energus Battery Packs, aluminum radiator, air cooling fans, and high voltage main power braces. Det

2 views • 5 slides

Cosmetic Lables Manufacturer from Kolkata India

Cosmetic Labels offered can be made available by us in different configuration choices so as to match up with the specific end usage demands of the customers. Made available in aluminum foil finish, these labels come in waterproof and heat-resistant finish and come with superior self adhesive proper

0 views • 4 slides

Understanding the Manufacturing Process of aluminum casting parts

Aluminum casting is a widely used manufacturing process in various industries, including automotive, aerospace, construction, and electronics. It involves pouring molten aluminum into a mold to produce a desired shape or part.

2 views • 5 slides

COPPER ELECTRICAL CABLE

Copper is used for electrical Cable because it's inexpensive, highly conductive, highly ductile, and thermal resistant. Copper is three times as thick as aluminum.

0 views • 5 slides

Permanent-Mold Die Casting Processes Overview

Permanent-mold die casting is a process where molten metal is injected into a mold cavity under high pressure, maintained during solidification. This process utilizes hot-chamber and cold-chamber die casting machines for casting various metals like zinc, aluminum, brass, and magnesium. Hot-chamber m

4 views • 7 slides

Understanding Patterns in Casting Process

Patterns play a crucial role in the casting process by creating replicas of objects with modifications, such as pattern allowances and core prints. They help in forming mold cavities, reducing casting defects, and minimizing costs. Various materials like wood, metal, and plastics are used for patter

1 views • 15 slides

Casting Net, livebait

Here is the world\u2019s best cast net in the USA. When you catch bait well, you will catch more fish. We have different type of casting nets for different depth and expertise. \/\/livebait.com\/

2 views • 3 slides

Flexible Packaging Market Flexible Packaging: Meeting the Needs of a Fast-Paced

Flexible Packaging Market By Packaging Type (Bags, Pouches, Films and Wraps, Others), By Raw Material (Plastic, Paper, Aluminum, Bioplastics, Polyethylene, Polypropylene, Polyethylene Terephthalate, Others), By Printing Technology (Flexography, Digit

0 views • 4 slides

Foundry Technology Unit 4: Gating and Risering System Overview

In Unit 4 of Foundry Technology, the focus is on Gating System, Risering System, and Quality Control in Foundry. The content covers components of the gating system, considerations for defect-free casting, proper design requirements, and factors affecting the functioning of the gating system. Key top

1 views • 94 slides

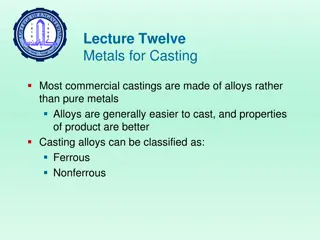

Overview of Casting Alloys: Ferrous and Nonferrous Options

Commercial castings are predominantly made from alloys rather than pure metals for better properties and casting ease. Ferrous casting alloys include cast iron and steel, each with unique characteristics and challenges. On the nonferrous side, aluminum, copper alloys, and zinc alloys offer various b

0 views • 15 slides

Electrical Conductor Ampacity Calculation Scenarios

Various scenarios are presented involving the calculation of allowable ampacity for different types of electrical conductors connected to circuit breakers with temperature limitations. The calculations consider factors like conductor material, size, temperature ratings, and ambient conditions to det

0 views • 140 slides

Physics Chapter 27 Practice Problems

The chapter 27 problems involve concepts related to current, drift speed of electrons, current density, resistance, resistivity, temperature effects on resistance, and power calculations. The problems cover scenarios such as cathode ray tubes, aluminum wires, gold wires, tungsten wires, conductor re

0 views • 12 slides

Understanding Solidification Process in Metal Casting

Solidification in metal casting involves nucleation and growth processes, impacting the final product's quality. Factors such as type of metal, thermal properties, and mold shape influence solidification. Homogeneous nucleation occurs below the equilibrium freezing point, while heterogeneous nucleat

1 views • 8 slides

Common Casting Defects in Prosthodontics: Causes and Prevention

Casting defects in prosthodontics can result from errors in the casting procedure, leading to issues like distortion, surface roughness, porosity, and incomplete detail. Various causes such as stress relaxation during wax pattern preparation can contribute to distortion, while factors like air bubbl

5 views • 27 slides

Metal Alloys Forming Operations: Forging, Casting, and More

Metal alloys undergo forming operations like forging, rolling, extrusion, and casting to change their shape through plastic deformation. Hot working and cold working processes are utilized to enhance mechanical properties. Techniques such as sand casting, die casting, and investment casting are empl

0 views • 18 slides

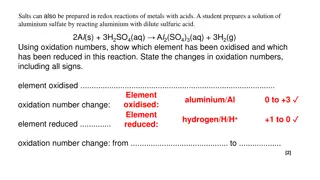

Understanding Redox Reactions in Chemistry

Salts can be prepared through redox reactions involving metals and acids. This interactive lesson covers oxidation numbers, identifying oxidized and reduced elements, and explaining electron transfer in redox reactions. Examples include reactions of aluminum with sulfuric acid and magnesium with cop

2 views • 12 slides

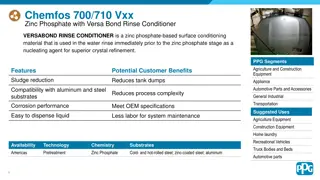

Chemfos 700/710 Vxx Zinc Phosphate with Versa Bond Rinse Conditioner

Chemfos 700/710 Vxx Zinc Phosphate with Versa Bond Rinse Conditioner is a zinc phosphate-based surface conditioning material used in the water rinse before the zinc phosphate stage. It acts as a nucleating agent for superior crystal refinement, offering benefits like sludge reduction, compatibility

0 views • 4 slides

Understanding Casting Defects in Metal Casting Processes

A casting defect is an undesirable irregularity in metal casting processes that may require correction or elimination. This article discusses the definition, types, remedies, causes, prevention, and conclusion of casting defects. It covers shrinkage defects, gas porosity, pouring metal defects, meta

0 views • 21 slides

Investment Casting Process: A Detailed Step-by-Step Guide

Investment casting process involves creating a wax pattern, assembling the pattern onto a sprue, coating with ceramic layers, de-waxing and firing, casting molten metal, knockout, finishing, testing, inspection, packing, and shipping. This detailed guide provides insights into each step of the inves

0 views • 10 slides

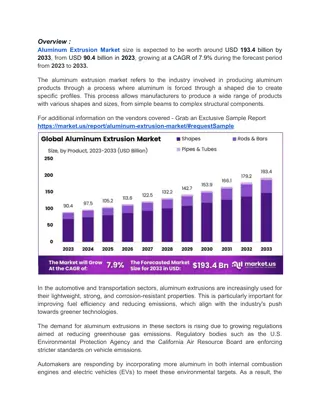

Aluminum Extrusion Market Thrives Despite Challenges: Innovations and Opportunit

Aluminum Extrusions Market; By Product(Shapes, Rods & Bars, Pipes & Tubes), By Type(2000 Series Aluminum, 3000 Series Aluminum, 5000 Series Aluminum, 6000 Series Aluminum, 7000 Series Aluminum), By Application(Building & Construction, Automotive & Tr

0 views • 4 slides

Fly Fishers International: Preserving Fly Fishing Legacy and Conservation Efforts

Fly Fishers International is an international non-profit organization dedicated to supporting, enhancing, and preserving fly fishing opportunities through environmental stewardship, education, and conservation efforts. With a history dating back to the 1960s, they focus on educating individuals in c

0 views • 28 slides

Manufacturing and Finishing Techniques of Plastic Products

Learn about various manufacturing processes of plastic products including casting, compression molding, transfer molding, and more. Explore the production of PMMA sheets through cell casting and other methods. Discover the intricacies of finishing and decorating plastic products with operations like

0 views • 39 slides

Comprehensive Guide to Casting and Splinting in Orthopedics

This comprehensive guide covers the essential aspects of casting and splinting in orthopedics, including their role in supporting and protecting orthopedic injuries, techniques for immobilizing fractures and sprains, conditions that benefit from casts and splints, possible complications to watch for

0 views • 9 slides

Operational Improvements for Aluminum Smelter in Trondheim

The aluminum smelter in Trondheim is facing challenges with high CO2 emissions and operational inefficiencies. To avoid hefty penalties and improve practices, recommendations include reducing amperage, enforcing operating procedures, meeting specifications for alumina and coke purchasing, renovating

0 views • 11 slides

Top Non-Ferrous Metal Products in Demand for Indian Industries (1)

1.Aluminum: The Versatile Metal\n\nAluminum is one of the most popular non-ferrous metals in India, and for good reason. It is lightweight, strong, corrosion-resistant, and highly conductive. These properties make it suitable for a wide range of industries including automotive, construction, electri

1 views • 2 slides

Step-by-Step Guide to Making Aluminum Foil Packages

Pre-cut heavier aluminum foil into a square, fold it to create a small-lipped package, fold the sides carefully, and ensure it fits a filter before sealing and storing in liquid nitrogen or freezer for preservation. Follow these steps for efficient packaging!

0 views • 7 slides

Friction Stir Welding of Aluminum Plate: COMSOL Simulation

Manufacturers use friction stir welding to join aluminum plates efficiently. This modern method generates frictional heat to soften the aluminum, allowing dissimilar materials to be welded together. The model in COMSOL considers heat transfer and boundary conditions to simulate the welding process,

0 views • 8 slides

Understanding Ray Tracing Techniques in Computer Graphics

Explore the fundamentals of ray tracing including recursive ray casting, ray casting vs. ray tracing, basic algorithms, shadows, reflections, refractions, and advanced illumination models like Whitted model and OpenGL's illumination model. Learn about casting rays from the eye, handling reflections

0 views • 50 slides

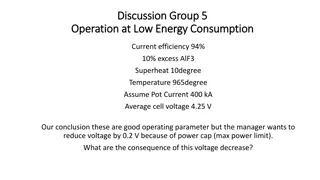

Optimizing Aluminum Smelting Operation Parameters for Energy Efficiency

The current efficiency of an aluminum smelting operation is at 94% with excess AlF3 superheat, operating at low energy consumption. However, to comply with a power cap, the manager wants to reduce the voltage by 0.2V. This voltage decrease leads to a heat balance problem, necessitating actions such

0 views • 6 slides

Powder Can Types: Vanadium and Aluminum with Various Flanges and Lids

Explore the different types of powder cans available, including Vanadium cans with aluminum flanges and lids, as well as aluminum cans with aluminum flanges, all designed for specific temperature and pressure measurements. The cans vary in size, lid diameter, screws used, and materials like steel, c

0 views • 4 slides

Metal Smelting and Electrorefining Techniques Explained

Smelting is a process involving the dissolution of pure alumina in a molten mixture of cryolite and fluorspar to extract metals like aluminum. Electrolysis is used to separate the metals where oxygen is liberated at the anode and the metal is deposited at the cathode. This process is illustrated wit

0 views • 29 slides

Exploring Cheaper Coke Options for Aluminum Production Cost Reduction

The discussion focuses on the potential cost-saving strategies in aluminum production by considering two coke options: existing coke (coke E) and a blend of 2/3 coke E and 1/3 coke A. The blend offers cost savings but may lead to quality loss and increased Net Carbon Consumption. Additionally, impro

0 views • 5 slides

Impact of Packaging Wastes on Environment and Recycling Efforts

Packaging wastes, including glass, aluminum, steel, and paper containers, contribute significantly to solid waste generation. In 2015, millions of tons of packaging products were discarded, with varying recycling rates and disposal methods. Glass containers accounted for a substantial portion of was

0 views • 8 slides

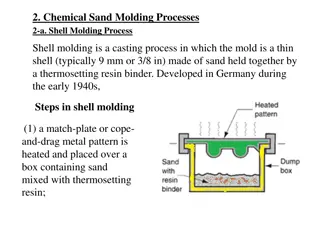

Overview of Shell and Sodium Silicate Molding Processes in Casting

Shell molding is a casting process involving a thin sand shell held together by a resin binder, offering advantages like smoother mold cavity surfaces and good dimensional accuracy. However, it can be costly for small quantities. Sodium Silicate Molding Process involves coating refractory materials

0 views • 19 slides

Best Casting Net, livebait

Here is the world\u2019s best cast net in the USA. When you catch bait well, you will catch more fish. We have different type of casting nets for different depth and expertise. \/\/livebait.com\/

2 views • 3 slides

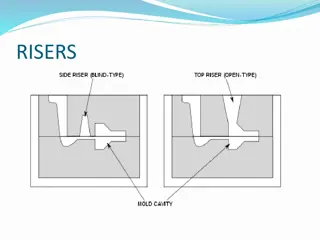

Understanding Risers and Casting Defects in Metal Casting Process

Risers are crucial in reducing shrinkage problems during casting by promoting directional solidification. Open versus blind risers have distinct characteristics affecting feeding and positioning within the mold. Rapid cooling rate and use of insulating compounds impact the efficiency of casting, whi

0 views • 41 slides

Understanding Aluminium Sand Casting Process

Aluminium sand casting is a cost-effective process commonly used in schools due to its affordability and achievable casting temperature. The process involves pattern making, moulding, pouring molten metal, removing sand, and cleaning the final workpiece. Quality patterns and moulds are crucial for s

0 views • 10 slides

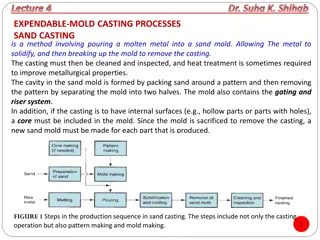

Expendable-Mold Casting Processes in Sand Casting: Lecture Insights

Sand casting is a process wherein molten metal is poured into a sand mold, left to solidify, and then the mold is broken to retrieve the casting. This casting method involves pattern making, mold creation, and uses a gating and riser system for complex geometries. Riser design is crucial in managing

0 views • 9 slides

Overview of Metal and Sand Casting Processes

Metal and sand casting are ancient manufacturing techniques dating back to 4000 B.C., allowing the production of complex shapes in various metals. The casting industry produces millions of kilograms of castings annually, primarily using materials like gray iron, ductile iron, aluminum alloys, and co

0 views • 13 slides