Basics of FRC Robot Control Systems: Electronics and Controls

Understanding the core components and functions of the control system in an FRC robot, covering pre-2015 and post-2015 control and wiring setups, major components like power distribution panels and speed controllers, importance of well-organized wiring, drive station essentials, battery and power considerations, speed controller functions, and various electrical devices for camera aiming, scoring, and more.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Robotics 101 Electronics and Controls Basics of an FRC Robot s control system.

The Control System The Control System is the Brain of the robot The control system receives input from the driver station and tells the robot what to do (e.g. drive forward, back up, shoot ball, etc.) It is very important to have a well-organized and wired control system A wiring issue can cost a match, or even a medal (Finals at the Buckeye Regional 2013) Finding issues with the control system would ideally be easy and quick Easy access to the control system should always be considered in the design process

Pre-2015 Controls and Wiring Major Components: NI cRio Sidecar Power Distribution Panel D-Link (wireless router) Speed Controllers

2015 and Future Controls and Wiring Major Components: NI roboRio Power Distribution Panel D-Link (wireless router) Speed Controllers

Drive Station Joysticks, USB multiplexer, Laptop/Classmate

Battery and Power Rated: 12V, 18 Amps-Hours Battery can provide 18 amps for one hour From our driving experience how long can a good charged battery drive our robot? Robot requires a minimum amount of power to turn due to friction of wheels on carpet Power = Volts X Amps so Amps = Power/Volts Charged good battery = 12.5 Volts Voltage drops as battery charge is consumed As voltage drops what happens to: Power? Amps?

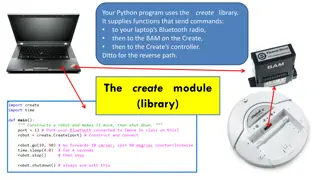

Speed Controller Functions Backwards/Forwards Faster/Slower Pulse Width Modulation (PWM) Jaguar Controller (Old) Talon SR Controller (Newer) Motor Victor Controller Talon SRX Controller (Newest)

Electrical Devices Camera Aiming, scoring Goal Tracking Limit Switch Control fixed position Potentiometer Variable control

Electrical Devices Photoelectric Limit Switch Non contact sensing/limit switch Sensing plunger back, Frisbee present Encoders Measure rotational speed Computer counts and adds pulses Gyro Measure robot direction/angle Used to drive straight or turn in auto

Motor List from 2012 Robot Description/Function Main robot drive Mech to lower bridge Extended front roller 1 Banebots 1st stage roller front 1st stage roller rear Upper roller/shooter feed Ball shooter wheel Shooter turret rotate 1 Ball singulator Wheel brake 1 Qty 4 1 Motor CIM AndyMark Sensor rqmt. /desire Would like encoders Potentiometer & Limit Switch None None None None RPM 1 1 1 2 Window Potentiometer 1 Window Limit Switch Window None AndyMark Window Banebots FP