Understanding Honda's VTEC System for Engine Performance Enhancement

The VTEC (Variable Valve Timing and Lift Electronic Control) system by Honda enhances the efficiency of four-stroke engines by utilizing two camshaft profiles. This innovative technology allows for optimized performance at both low and high RPMs, controlled by the Engine Control Unit (ECU) based on various engine and vehicle parameters. Learn how VTEC differs from standard VVT, the importance of cam profiles, and the principles behind VTEC's operation.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

i-VTEC Submitted by P.Pradeep 11m139

So why do we need this?? To increase performance !! One method for increasing performance includes forced induction, as with models such as the Toyota Supra and Nissan 300ZX which used turbochargers and the Toyota MR2 which used a supercharger. The other option is to change cam timing or profile.

VTEC VTEC (Variable Valve Timing and Lift Electronic Control) is a system developed by Honda to improve the volumetric efficiency of a four-stroke internal combustion engine. The VTEC system uses two camshaft profiles and hydraulically selects between profiles. It was invented by Honda engineer Ikuo Kajitani

VVT vs. VTEC It is distinctly different from standard VVT (variable valve timing) which advances the valve timing only and does not change the camshaft profile or valve lift in any way. There are basically N number of ways of doing this ! Let us consider Toyota,Ferrari,Honda

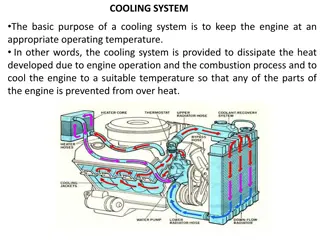

CAM !! Cams are driven by engine and they provide the force to push the valve. This is usually done with the aid of a rocker arm. The shape of the cam decides the timing and the distance the valve travels. Cam friction can even contribute to 25% of total friction in engine(springs contribute to inertia)

Principle The VTEC system provides the engine with multiple cam lobe profiles optimized for both low and high RPM operations. In basic form, the single shaft of a conventional engine is replaced with two profiles

The switch over!! one optimized for low-RPM stability and fuel efficiency, and the other designed to maximize high-RPM power output. The switching operation between the two cam lobes is controlled by the ECU which takes account of engine oil pressure, engine temperature, vehicle speed, engine speed and throttle position.

Using these inputs, the ECU is programmed to switch from the low lift to the high lift cam lobes when the conditions mean that engine output will be improved. At the switch point a solenoid is actuated which allows oil pressure from a spool valve to operate a locking pin which binds the high RPM cam follower to the low RPM ones.

In a nut shell i-VTEC regulates the opening of air-fuel intake valves and exhaust valves in accordance with engine speeds By regulating valve opening to match engine speed, the agile i-VTEC engine adjusts its characteristics to realize both superior power and low fuel consumption.

Advantages Increased Power Fuel efficiency-low fuel consumption High performance Lower emissions