Cutting-edge Equipment Suite: TEL Synapse Series for Sale

Explore the advanced TEL TBDB Tools Suite featuring a fully-automated Tokyo Electron Synapse-series adhesive coater, bonder, and mechanical debonder. The suite includes the TEL Synapse V coater, TEL Synapse V bonder, and TEL Synapse Z debonder, offering precise specifications and capabilities for temporary bonding and debonding processes. Additionally, ensure compliance with full SEMI S2, S8, and S22 standards for handling 300mm wafers. Take a closer look at the cutting-edge technology and functionalities of these equipment pieces.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

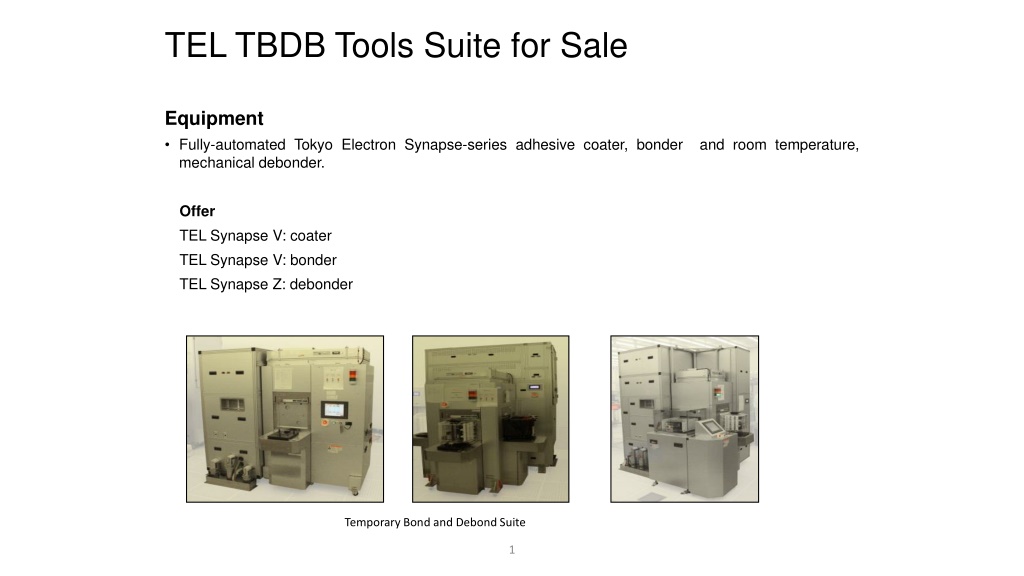

TEL TBDB Tools Suite for Sale Equipment Fully-automated Tokyo Electron Synapse-series adhesive coater, bonder and room temperature, mechanical debonder. Offer TEL Synapse V: coater TEL Synapse V: bonder TEL Synapse Z: debonder Temporary Bond and Debond Suite 1

TEL Synapse V: Coater Specifications Two pump dispense lines and one N2 pressure dispense line Adhesive dispense lines 1L bottle for pressure tank, 1L NOWPak for pump dispense lines Adhesive delivery container type High viscosity adhesive line 0.3MPa (for up to 10,000cp) Low viscosity adhesive line 0.2MPa (for up to 100cp) 20L pressure tanks: Solvent cabinet 2 containers switchable online 2 containers backup Bevel rinse Two nozzles Back rinse Two nozzles EBR 0.7-35mm +/- 0.3mm TEL Synapse V: Coater Spin speed 0-4000rpm +/- 1rpm Programmable position including dynamic dispense Dispense head control Up to 350 C +/- 2% Up to 350 C +/- 2% Atmosphere hotplate N2 hotplate 2 cooling plates control by process cooling water Cold plate Footprint: 04.94 sq m 10L drain tank for nozzle bath 53.15 sq ft Drain tank 10L drain tank for spin cup 2

TEL Synapse V: Bonder TEL Synapse V: Bonder Pressure 49kN 200 C Temperature Vacuum level 30Pa X,Y: +/- 30 m; Theta +/- 0.02 Alignment TEL Synapse V: Bonder Footprint: 04.76 sq m 51.24 sq ft 3

TEL Synapse Z: Debonder TEL Synapse Z: Debonder Type Mechanical peel Debond initiation Physical initiation Force Up to ~50N Wet clean station 3 solvent dispense lines (2 center, 1 edge) 20L pressure tanks: 2 containers switchable online (center) Solvent cabinet 2 containers backup 1 container edge dispense Spin speed 0-1500rpm +/- 1rpm Drain tank 10L Wafer loading 300mm metal tape frames (7 wafers max) Carrier unloading 300mm FOUP TEL Synapse Z: Debonder Footprint: 04.6 sq m 49.7 sq ft 4

Full SEMI S2, S8, S22 compliance 300mm FOUP loading Handling 300mm Si wafers Pre-trim wafers 300mm metal tape frame 5