Best Practices for Fresh Tissue Stability Testing

Establishing stability of fresh tissue samples is crucial for accurate residue analysis. Homogenization of tissue samples is recommended to ensure uniform distribution of analytes and prevent enzymatic activity. This process aids in maintaining sample integrity and minimizing freeze/thaw effects. Proper collection, processing, and storage are essential to establish stability, as outlined in industry guidelines and regulatory requirements. Follow these best practices to ensure reliable results in assessing residue concentration in animal tissues.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Industry Input: CVM Requirement 48 HR Stability Testing Animal Health Institute August 14, 2019

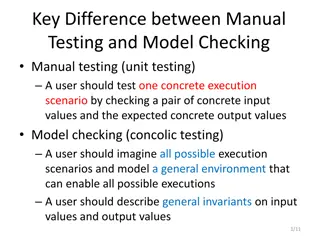

Fresh Tissue Definition Definition of T=0 to Establish Fresh Sample: Residues at T=0 are established using conditions that best preserve the analyte (marker residue) so that analysis at T=0 reflects the concentration present at slaughter (fresh tissue) (Ref 1). 2

Best Practices to Establish T=0 1. Tissue must be homogenized tissue not bulk (Ref 2) Can only establish stability in homogenized samples. Fresh tissue is collected from each animal, cubed, then ground with dry ice to generate a homogenous sample from which an aliquot is assayed. The physical disruption of cells achieved by the homogenization process is essential to cease enzymatic activity. The remaining homogenized tissue aliquots are frozen, and each aliquot is subsequently assayed for stability testing. This process eliminates freeze/thaw activity associated with bulk sample. 2. Assaying a piece, or pieces, of fresh tissue from a bulk sample does not ensure homogeneity since the bulk sample is not completely ground and mixed prior to sampling. Stability testing of analytes in aliquots from frozen bulk tissue has been shown to produce lower concentrations than when the same tissue is homogenized and partitioned into aliquots prior to freezer storage. References 3 and 5 support the use of homogenized tissue instead of bulk tissue for stability testing. 3. Processing and storage conditions for tissues must be appropriate for the analyte of interest and are established during method validation and total radioactive residue depletion studies. 3

VICH 48 (R): Marker Residue Depletion Studies to Establish Product Withdrawal Periods 2.3.6. Sampling 2.3.6.1. General Considerations Following euthanasia, edible tissue samples in sufficient amounts should be collected, trimmed of extraneous tissue, weighed and divided into aliquots. If the analysis can not be completed immediately, the samples should be stored under frozen conditions pending analysis. If samples are stored after collection, the Sponsor generally bears the responsibility for demonstrating residue stability through the time of assay. 4

CVM Requirements for 48 Hour Stability Testing CVM presentation on Incurred Analyte Storage Stability Testing (AHI Quarterly Meeting; Feb 13, 2019) Incurred analyte stability, as close to the time of sample collection as possible and, at a maximum, within 48 hours following collection is required for each species and for each tissue for which you wish to establish a tolerance. We consider a sample collected, shipped and analyzed within 48 hours to be fresh and logistically possible given the readily available options for shipping samples overnight on dry ice. We consider it feasible to begin the analysis within 48 hours. 5

Challenges with 48 Hour Stability Testing 1. Location of Testing Facilities Most sponsors do not have an In-Life and Analytical Testing Facilities on site or in the same geographic region. For some species (such as bees, aquaculture, etc.), In-life Testing Facilities are only available at international sites. 2. Number of animals required for 48 hour stability testing Due to animal to animal variability, more than a single animal (large animals) should be dosed to ensure that each tissue has a measurable amount of incurred residues. For smaller animals (chickens, turkeys, etc.): tissues from animals slaughtered at the same timepoint should be combined to ensure adequate tissue samples are available for multiple aliquots for stability testing. 6

Challenges with 48 Hour Stability Testing 3. Use of additional personnel at CROs increases study cost by ~ 25% Additional manpower is needed at the In-Life Testing Facility during slaughter to prevent contamination during tissue removal (liver, kidney, muscle and skin fat), processing, homogenization, and documentation. Additional manpower is needed at the Analytical Testing Facility to inventory the shipment and weigh each tissue aliquot. Longer working day (>10 hours) may be required. 4.Tissue preparation and transportation to Analytical Testing Facility Cryo-homogenization of each tissue (especially skin with fat attached) ensures that a uniform sample is generated from which aliquots are taken for stability testing. Processing also helps decrease enzymatic or other processes contributing to changes in analyte levels. When the In-Life and Analytical Testing Facilities are located in different geographic regions, tissues are shipped overnight with dry ice to maintain the integrity of the samples during transport. Incurred samples shipped overnight from the west coast to the east coast are typically delivered within 24 hours but could take up to 72 hours during inclement weather, which adds additional processing time prior to extraction. Incurred samples shipped from international In-Life Facilities take approximately 5 days from shipment to arrive at the Analytical Facility. It is common for customs clearance to take 1 week. 7

Challenges with 48 Hour Stability Testing 5. Stability parameters established under method validation Are not taken into account in the 48 hour requirement 6.Method performance and failure of analytical instrument If quality control samples and method performance criteria are not achieved, a new set of samples may need to be extracted and assayed. A repeat extraction will add additional time from the time of slaughter to initial extraction. 7. 48 Hour stability testing as part of a residue depletion study Additional animals must be included in the study for incurred sample generation. Tissues must be collected, processed, and extraction must begin within 48 hours from slaughter. Makes the study more complex for planning, execution, and reporting Additional manpower is required at the In-Life and Analytical Testing Facilities to slaughter, process, and assay tissues from the extra animals for stability testing. This is not the best time to establish incurred residue stability if it fails it puts the entire study at risk. 8

Stability Testing Three Scenarios Scenario 1 In-Life and Analytical Facility in the same geographic location This is extremely rare and still may not be possible. Scenario 2 In-Life and Analytical Testing Facilities are in different geographic locations Tissues are processed at the In-Life Facility before shipping to the Analytical Facility This is the current process established over many years by sponsors and is the recommended best practice. In-Life Facilities have the equipment and expertise to process tissues. Processing tissues disrupts cell walls and inactivates enzymes, which is important to preserve incurred analytes. This allows for the option to weigh tissue aliquots prior to shipping to avoid multiple freeze/thaw cycles. Scenario 3 In-Life and Analytical Testing Facilities are in different geographic locations Bulk tissue are shipped on dry ice. Adequate dry ice must be included in the sample to keep frozen during shipment. Shipping can take from 24-72 hours domestically and 1 week internationally. Shipping bulk tissue does not shorten timeline and may compromise stability. Samples should at a minimum be diced into small pieces and frozen prior to shipping. Not all analytical labs have expertise, equipment, or extra manpower for cryo-processing samples. 9

Stability Testing Steps Required for Tissue Analysis Time 0 24 hours (Day 1) Treated animals are prepared for slaughter. Necropsy common practice is to sacrifice multiple animals at one time. Tissue Collection Could be target tissue or multiple tissues. Multiple tissues require careful handling and changing of equipment to prevent cross contamination. Each tissue is cubed or chopped into smaller pieces and placed into a labeled container . Each tissue is frozen overnight Current and best practice. If samples are not frozen, it will require more dry ice for cryo- processing. This means more time to sublime dry ice prior to shipment. This is an important step to prevent degradation of tissue This is analyte specific. Time: 25 48 hours (Day 2) Chopped tissue is homogenized together with dry ice using a blender or chopped tissue is placed in a liquid nitrogen bath and frozen prior to grinding. Frozen ground tissue is placed in a container and stored in a freezer (-20 C) for ~ 18 hours to sublime dry ice. Time: 48-72 hours (Day 3) Sample is sub-sampled and shipped. Time: 72-96 hours ( Day 4) Samples are received at Analytical Facility. Samples are inventoried and weighed. Sample extraction is initiated. This scenario maintains integrity and represents how residue depletion study samples will be collected, processed and stored. 10

Stability Testing Domestic and International Analytical Laboratory 11

Stability Testing Additional Considerations In practical terms, Day 4 is the timepoint when an analytical lab would receive samples. For tissues that have a small size for example chicken livers or kidneys Multiple animals are required to generate adequate tissues to analyze multiple time-points. Combining tissues from multiple animals ensures an adequate supply of each homogenized tissue for stability testing. Important to obtain a homogeneous sample. If multiple tissues require stability testing, they cannot all be extracted on the same day The target tissue may not be known at the time of stability testing, thereby requiring stability in all edible tissues. Instrument space and limitations of extract stability may affect how long it takes to achieve a time zero sample analysis. Residue (marker) levels may be vastly different, requiring additional contamination prevention concerns. Method may be different for various tissues. 12

Conclusion Based on reasons previously presented, AHI proposes the timeline 5-7 days after tissue collection depending on geographic location. In-Life and Analytical Facilities in Same Country: Incurred analyte stability (marker residue), should be determined within 5 days following collection for each tissue for which a tolerance is proposed. Consideration should be given to the available fortified data. In-Life and Analytical Facilities in Different Country (international shipping required) : Incurred analyte stability, should be determined, within 7 days following collection for each tissue for which a tolerance is proposed. Because of extenuating circumstances (i.e. weather and customs), even 7 days may not be achievable. Therefore, consideration should be given to the available fortified data, in situation where 7 days was not achieved. Incurred analyte stability (marker residue) is found to be stable based on: the initial analysis t=0 (within 5-7 days after tissue collection) and again at t=d (d=timepoints after t=0, for example 30 days) fortified tissue data would establish that analysis at t=0 and times within the analysis window reflect the concentrations of the incurred residue present at necropsy. 13

References 1. Reed, G.A. 2016. Stability of drugs, drug candidates, and metabolites in blood and plasma. Curr. Protoc. Pharmacol. 75:7.6.1-7.6.12. Van de Merbel, et al., 2014. Stability: Recommendation for Best Practices and Harmonization from the Global Bioanalysis Consortium Harmonization Team. The AAPS Journal. 16(3): 392-399 Johnson, R.D., Botch-Jones, S.R., 2013. The stability of four designer drugs: MDPV, Mephedrone, BZP, TFMPP in three biological matrices under various storage conditions. Journal of Analytical Toxicology. 37:51- 55. Garofolo, et al., 2011. 2011 White Paper on Recent Issues in Bioanalysis and Regulatory Findings from Audits and Inspections. Bioanalysis. 3 (18): 2081-2096 Verdon, et al., 2000. Stability of penicillin antibiotic residues in meat during storage. Journal of Chromatography A. 882: 135-143. 2. 3. 4. 5. 14