Fundamentals of Process Integration, Simulation, and Design

This course covers the fundamentals and applications of process integration, simulation, and design. Students will learn systematic tools for synthesizing process flow sheets, apply principles of process economics, and gain skills in using computer-aided engineering systems for chemical simulations. Topics include process design, heat integration, mass integration, and economic analysis of processes.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

-1- Process Integration, Simulation and Design http://t0.gstatic.com/images?q=tbn:Gtb43qoxnyzWFM:http://chemeng.nmsu.edu/photos/che_nmsu_logo.gif 1

Aims: 1. Introduce the fundamentals and applications of process integration, simulation and design 2. Learn systematic process-integration tools for the synthesis, development, and screening of potential process flow sheets 3. Apply tools of mass integration, heat-integration, separation processes and environmentally-benign and inherently-safe designs 4. Analyse principles of process economics including evaluation of fixed and operating costs, depreciation, and profitability analysis 5. Apply computer-aided engineering systems simulations of chemical- 2 2

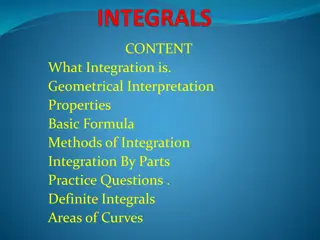

Intended Learning Outcomes ILOs Cognitive Skills Knowledge/Understanding Synthesise direct-recycle networks Screen and synthesize networks of mass exchangers Evaluate energy targets (for minimum heating and cooling utilities) Screen and select mass and heat utilities Apply economic principles to assess the design of a project Evaluate mass targets (fresh usage, waste discharge, yield, etc.) for a given process Concepts associated with process design, process integration and simulation Key/Transferable Skills Use ASPEN Hysys to simulate various scenarios of units and groups of units Use simulation to analyse process performance, identify opportunities, troubleshoot problems, and recommend changes Work effectively in teams Play roles (team leader, process engineer, and consultant) Prepare a professional design report 3 3

Topics: Chemical process design Nature of chemical process design and integration Onion diagram hierarch for process design: design stages, process integration week 1 Process design and simulation, simulation basis, tools, procedure week 2 week 3 Targeting for Process Design and Integration, alternatives screening Heat integration, heat exchanger network for heat recovery Composite curves The heat recovery pinch The problem table algorithm Utility selection Heat exchanger network design week 4 week 4 week 5 week 5 week 6 week 6 Mass integration Overall mass targeting Direct recycling strategies source/sink mapping Material recycling Pinch diagram Mass exchanger network and design week 7 week 7 week 8 week 9 week 10 Economic analysis of processes week 11

References 1. Smith, R., Chemical Process Design and Integration Wiley, New York (2005). El-Halwagi, M. M., Process Integration , Academic Press (2006) Additional References Reading Peters, M. S., K. D. Timmerhaus, and R. E. West "Plant Design and Economics for Chemical Engineers," Fifth Ed., 2002, McGraw Hill, New York. Biegler, L. T., I. E. Grossmann, and A. W. Westerberg, Systematic Methods of Chemical Process Design. Prentice Hall, New Jersey (1997). Douglas, J. M., "Conceptual Design of Chemical Processes," 1988, McGraw Hill, New York. 2. 3. 4. 5. 6.

-1- Chemical Process Design: Nature of chemical process design Onion diagram hierarchy for process design http://t0.gstatic.com/images?q=tbn:Gtb43qoxnyzWFM:http://chemeng.nmsu.edu/photos/che_nmsu_logo.gif 6

1. Definition late 1970 s. It refers to the system-oriented, thermodynamics-based, integrated approaches to the analysis, synthesis and retrofit of process plants. Ferenc Friedler, 2010 Process integration is a family of methodologies for combining several processes to reduce consumption of resources or harmful emissions to the environment.

2.objectives 1) To integrate the use of materials and energy. 2) To minimize the generation of emissions and wastes.

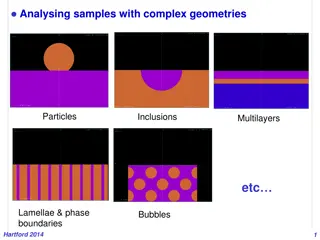

Three concepts of PI building 1. Consider the big picture first by looking at the whole manufacturing process (interconnected processing units, process, utility and waste streams) 2. Apply process-engineering principles, such as thermodynamics and mass and energy balances (establish attainable performance ( task) [use of materials and energy and the generation of emissions and wastes (e.g., the minimum utility consumptions, minimum CO2 and NOx emission levels, minimum freshwater requirement, etc.). 3. Finalize the details of process design