Preventing Incidents in Lifting Operations: Importance of Clear Roles and Responsibilities

Proper planning and communication are crucial in preventing accidents during lifting operations. This safety moment highlights a scenario where a routine lift of 900kg resulted in a major incident due to inadequate preparation, unclear responsibilities, and lack of adherence to safety protocols. By emphasizing the importance of a "Stop the Job" culture, comprehensive toolbox talks, clear roles and responsibilities, up-to-date lift plans, and effective communication, organizations can enhance safety measures and prevent similar incidents from occurring.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Making a meal of lifting operations Disclaimer: this safety moment is designed to prevent similar incidents occurring. All guidance herein is provided in good faith and Step Change in Safety nor its member companies accept responsibility for any inaccuracies or omissions contained within this safety moment.

Lifting operations Lifting operations 12 bidons of cooking oil (24kg each) 14 bags flour (16kg each) 9 bags potatoes (20kg each) 5 bags onions (20kg each) 4 boxes apples (2.6kg each) 8 boxes milk (12kg each) Total 900kg A routine lift of 900kg pallet of food was to be lifted from the dockside, through a hatch, into galley stores Several people involved in the lift did not attend or were late for the toolbox talk Roles and responsibilities for the lift were not clear Regardless of this, the lift went ahead What could have happened?

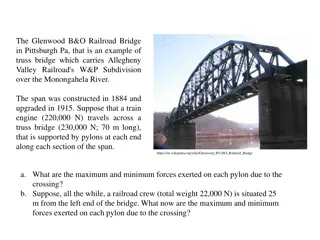

Lifting operations Lifting operations What happened? 1. The pallet collided with the corner of the hatch causing most of the 900kg to fall 7.2m to the deck area below Banksman Point of pallet contact Deck 6 Upper hatch combing to lower hatch deck (7.2m) 2. The dropped load narrowly missed the storeman View from fwd of hatch loading area Storeman Area fallen items landed Deck 4 Path of storeman Why might this have happened?

Lifting operations Lifting operations What caused the incident? The load wasn t properly secured Crane operator didn t stop the job when he saw the load was unstable he wasn t comfortable challenging his supervisor The load was still swinging when it entered the hatch misunderstanding about who was in charge of the lift Inadequate task risk assessment and lifting plan no reference to pausing above the hatch Task responsibilities not established because toolbox talk was not fully attended people arrived late How do you ensure this doesn t happen at your worksite?

Lifting operations Lifting operations Good practice guidance Stop the Job culture is essential throughout the organisation Everyone involved in a task should take part in the toolbox talk Roles and responsibilities should be clear and understood before starting the job Ensure lift plans and risk assessments are up-to-date, competently agreed and followed Communicate with your team Ensure time constraints do not affect safe operations See Step Change in Safety document: Lifting & Mechanical Handling Guidelines

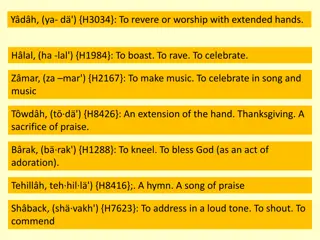

Lifting operations Lifting operations Which of the 7Cs are involved in this safety alert? Change management Communication Complacency Control of work Competence Culture Commitment Did this presentation result in discussion that could lead to creating another alert to share with industry? Please contact : info@stepchangeinsafety.net