Mechanically Driven Biodiesel Reactor for Village-Level Production

This project introduces a mechanically-driven biodiesel reactor designed to empower older women caregivers in Kenya by utilizing a pedal-operated system for biodiesel production from non-edible oils. The reactor, driven by a treadle sewing machine, aims to provide a sustainable energy solution while leveraging the skills of the target community. The methodology involves theoretical components, design calculations, engineering drawings, and practical measurements to fabricate the reactor, focusing on power transmission, drive system, vessel, and agitator components.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

PROJECT PRESENTANTION MECHANICALLY DRIVEN BIODIESEL REACTOR

MECHANICALLY (PEDAL) DRIVEN VILLAGE-LEVEL REACTOR FOR PRODUCTION OF BIODIESEL FROM NON- EDIBLE OILS. PRESENTERS: LILIAN JAMUNGA MOTONGORI PROJECT PARTNER:BRIAN ONYANGO AGANDA PROJECT SUPERVISOR: ENG. MUHAMMED A. SWALEH

INTRODUCTION In the early 2000, almost a quarter of the middle-aged population in Nyanza province in Western Kenya succumbed to AIDS, leaving orphans in the care of their grandmothers- Older Women Caregivers (OWCs). These women (who farm) often have severe health issues, caused primarily by malnutrition and are challenged to grow enough produce to feed their families, due to crop failures caused by droughts. Many of them practise tailoring as a source of income and this is not always enough for their needs. Their sewing machines are treadle operated and being able to use the same sewing machine in driving the reactor would be effective and relevant to their skills.

ABSTRACT This project is part of an ongoing program for the Matangwe community health centre based in Bondo, Kenya which involves the production of biodiesel through the batch process under the mission: Fuelling older women caregivers for better health There are different processes involved during the biodiesel production and the biodiesel reactor is just a part of it. This project focuses on the design and fabrication of the biodiesel reactor. The reactor uses power from a treadle sewing machine to run a turbine stirrer in mixing yellow orliender oil with esters in transesterification to produce biodiesel.

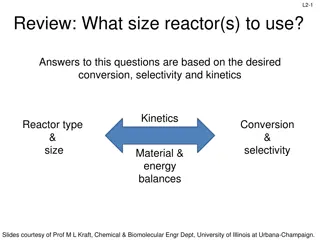

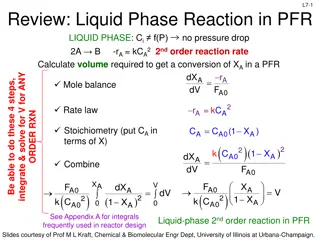

METHODOLOGY The following methods were used in collecting data, computing, evaluating and analyzing the data and finally fabricating the reactor: Use of theoretical components Design calculations using available formulas. Engineering drawings done using engineering softwares such as Solid works. Experiments done to get done. Practical measurements of components. BIODIESEL REACTOR DESIGN The biodiesel reactor consists of the following: Power transmission Drive system Vessel Agitator Outlet Important considerations in the designing Determination of amount of energy required or power required for satisfactory performance of mixing operation. Process has to be well defined e.g., a mixing system is to be designed to make up and hold in uniform suspension a 15% slurry. Description of the components to be mixed. Their properties at initial stage, final stage, overall specific gravity, initial and final viscosity, concentration etc. Details of the tank geometry. Outline of the mixing cycle: It depends upon the nature of the operation. Decide whether the process is a batch, semi-continuous or continuous etc

METHODOLOGY (CONT) The following factors were considered in the design Chemical and physical properties of fluid. Power transmission from the user to the sewing machine and through the horizontal and vertical shafts and finally to the reactor through the impellors. Material selection Shaft design. Bevel gear design. Impellor/ agitator design Vessel design Bearing design Coupling design

OBJECTIVE The people of Bondo community practice farming as a source of food for their families and they suffer a lot while tilling the land manually since it is more time consuming and tiresome. The few who are able to own tractors find it expensive to operate the tractors due to the high cost of diesel fuel. There has been unemployment, low income per capita, higher costs incurred on imported fuel used in farming locomotives as well as underdevelopment in the Bondo area. The main objective of this project is to Design and manufacture a pedal driven biodiesel reactor for production of biodiesel from non-edible oils that is locally available from the yellow oliender that grows in the area The village-level biodiesel (VLB) project at the Matangwe Community Health centre in Kenya sought to increase the production and consumption of high nutrient foods, to provide OWCs with a source of income and in the long term, have a positive impact on their access to and use of health services. Use minimum power requirement. Achieve efficient mixing in optimum time. Have a Best possible economy. The equipment to have minimum maintenance, durable and trouble free operation. Achieve compactness

RESULTS AND DISCUSSION SPECIFICATIONS OF THE DESIGNED BIODIESEL REACTOR Parameter Specifications The following were the Tank diameter (Inches) 10 Length of tank (Inches) 18 processes that were used during Liquid height (Inches) 12 Vessel volume (Litres) 11.25 fabrication: Shaft length (Inches) 20.25 Shaft diameter (mm) 17 Cutting Shaft material Stainless steel Type of gear Bevel Grinding Gear ratio 1:1 Impellor diameter (Inches) 4 inches Welding Number of impellors 1 Number of blades 4 Fitting Tip speed(rpm) 175 Type of turbine Flat blade Type of Mixing Laminar Power absorbed (Watts) 4 Mixing time (Minutes) 6.43

RESULTS AND DISCUSSION The following is a diagram showing the process of power transmission in the biodiesel reactor. Human power Sewing machine Horizontal shaft (coupled) Bevel gears Vertical shaft Impeller

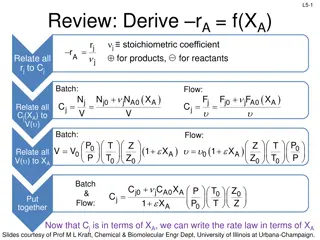

RESULTS AND DISCUSSIONS Formulae The total mixing time will be 6.4minutes

RESULTS AND DISCUSSION BUDGET

CONCLUSION The design and fabrication of the reactor was done, it was connected to the sewing machine through a coupling and finally got to work. The movement of the treadle at the sewing machine would be able to rotate the impeller in the reactor. Thereby allowing the oil seeds from yellow oleander to be mixed well with other components to form the biodiesel. It is able to do the mixing within 6.4 minutes and a capacity of 11.25 litres when manually driven at a budget cost of $56

RECOMMENDATION It is recommended that maximum volume of 11.25 litres be NOT exceeded since vortexing wll occur and the mixing will not be properly done. This project is recommended to people in areas of no electricity and need an extra source of income by sale of biodiesel produced

REFFERENCES Atkinson, C. J. and Brooks, L. (2005) In the Age of the Humanchine, In Proceedings of International Conference on Information Systems (ICIS), AIS, Las Vegas, USA. Khurmu, R. S. and Gupta, J. K. (2012) Theories of Machine , S.chad & company Ltd, New Delhi. William, V. and Jeffery, H. (2012) Human Powered Generation- Seesaw, Senior Project, Department of Electrical Engineering, California Polytechnic State University. Agitation, Gordon & Breach, New York, 1985.

REFFERENCE Butt, J. B. (2000). Reaction Kinetics and Reactor Design. New York: Marcel Dekker Inc. Noureddini, H. Harkey, D., and Medikonduru, V. (1998). Continuous process for the conversion of vegetable oils into methyl esters of fatty acids. J. Am. Oil Chem Hofman, V. (2003). Biodiesel Fuel. NDSU Extension Service, North Dakota State University of Agriculture and Applied Science. Holland and Chapman, Liquid Mixing and Processing in Stirred Vessel , Reihold Publishing Corporation, London