Ammonia Reactor System Design and Optimization Study for High Efficiency

This material discusses the design and optimization of an ammonia synthesis reactor system for maximizing conversion efficiency while minimizing CAPEX costs. Various factors such as managing heat effects, reaction runaway prevention, and cooling profiles are explored. Recommendations include using a fired heater and a single jacketed reactor with high pressure steam generation. The analysis involves Aspen simulation with FNH3 maximization and considerations for material construction. The memo includes reactor feed and exit temperatures, ammonia flow rates, and total bare module costs. The goal is to achieve the highest NH3 yield efficiently.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

HW 3 Debriefing Terry A. Ring Chemical Engineering University of Utah Aspen File : Ammonia Synthesis Reactor Design-4.apwz MathCadfile: HW 3 Ammonia Reactor

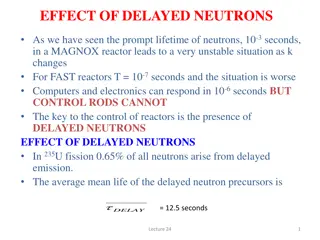

Managing Heat Effects Reaction Run Away Exothermic Reaction Dies Endothermic Preventing Explosions Preventing Stalling Most Conversion with least CAPEX Cost

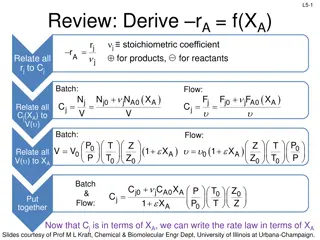

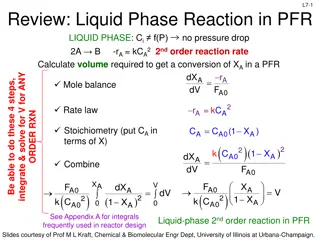

Ground Work for Reactor 0.5 N2 + 1.5 H2 NH3 Conversion Rate=0.001, 0.01, 0.1, 1 Temperature (K)

Ground Work for Reactor 0.5 N2 + 1.5 H2 NH3 Conversion Cooling Rate=0.001, 0.01, 0.1, 1 Temperature (K)

Ground Work for Reactor 0.5 N2 + 1.5 H2 NH3 Conversion Mixing Rate=0.001, 0.01, 0.1, 1 Temperature (K)

Ground Work for Reactor Cooling Profile Conversion Feed Temperature Temperature (K)

Aspen Simulation with FNH3 Maximization Optimized Thermo Fluid T & P Optimized Feed Temp for B8 and B3 Optimized Split to get highest FNH3

Memo Questions Description of the reactor system you think is best for this application. Fired Heater then a single reactor with a jacket generating high pressure steam Material of Construction for any or all Reactors, heat exchangers and Fired Heaters Carbon Steel Reactor, Stainless Steel Fired Heater Reactor Feed Temperatures and Reactor Exit Temperatures 507C Feed T, 301C Exit T Ammonia Flow in kmol/hr leaving your reactor system. This is related to the single pass conversion, more ammonia flow = higher conversion. 13536.96 kmol/hr (XN2=50.5%) This is also the case for the 3 reactor + interstage cooler simulation Total Bare Module Cost (CBM) for your reactor system including fired heater(s), S&T heat exchangers (if any), reactors and catalyst. $ 55,897,463 for the one jacketed reactor generating steam Please submit your Excel files and your Aspen Files into Canvas.

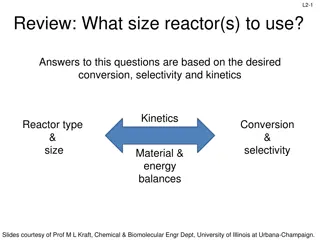

CAPEX Only One Reactor

Flow Sheet Improvements Steam Product Feed Fired Heater RX Steam Feed Fired Heater RX HX HX Product