Contemporary Issues in Industrial and Management Engineering

Explore the evolution of manufacturing systems from the Industrial Revolution period through key milestones in history to the implementation of Lean Manufacturing principles. The journey encompasses significant advancements in technology, production processes, and management strategies, leading to t

0 views • 40 slides

Introduction to Lean Management: Principles and Methods for Efficient Organization

Lean management, originating from the concept of lean production developed by MIT researchers in 1992, focuses on minimizing waste and maximizing value in operational processes. This philosophy has been widely adopted across various industries and sectors, evolving into lean thinking and influencing

7 views • 59 slides

Evolution of Manufacturing Systems: From Handicraft to Automation

The evolution of manufacturing systems traces back to manual craftsmanship and has progressed into automated processes using machines and computerization. Specialization of tasks, organization of production systems, and different categories of manufacturing methods have played crucial roles in shapi

7 views • 19 slides

Third-Party Manufacturing Services

Unimarck Pharma Provides Third-Party Manufacturing Services in India that offer a wide range of pharma manufacturing services, including contract manufacturing & private-label pharma manufacturing.

10 views • 4 slides

Understanding Lean Manufacturing: A Comprehensive Overview

Lean manufacturing is a strategic approach focused on continuous improvement and waste elimination in processes. Originating from Henry Ford's assembly line, it evolved with Taichi Ohno and Kiichiro Toyoda into the Toyota Production System. Lean emphasizes efficiency, effectiveness, and continuous i

1 views • 8 slides

Lean Manufacturing: Introduction, Philosophy, History, and Practices

Lean manufacturing is a strategic approach focused on continuous improvement by eliminating waste in processes. The philosophy originated from Henry Ford's assembly line and further developed by Toyota with the Toyota Production System. This content explores the core principles, history, and key dif

1 views • 6 slides

Lean Manufacturing: Improving Efficiency and Sustainability

Lean manufacturing principles such as 5S and Total Preventative Maintenance (TPM) focus on eliminating waste, optimizing processes, and ensuring sustainable improvements in production systems. Mistake-proofing, organization, cleanliness, and proactive equipment maintenance are key strategies discuss

0 views • 9 slides

Overview of Manufacturing Systems: Types and Characteristics

Manufacturing systems are essential for transforming raw materials into finished products. This overview covers the types of manufacturing systems, such as job shops and flow shops, along with their characteristics, advantages, and disadvantages. It also introduces modern manufacturing systems like

0 views • 23 slides

Core Principles and Tools of Lean Six Sigma Green Belt

Combining the quality improvement strategies of Six Sigma with the lean waste reduction principles, Lean Six Sigma Green Belt is a potent methodology.

1 views • 8 slides

Introduction to Lean Manufacturing Principles and Practices

Explore the fundamentals of Lean Manufacturing through a simulation-based course agenda at Mountain Pointe High School. From identifying value-added activities to eliminating waste, learn how to optimize processes to deliver value to customers efficiently. Dive into Lean principles, value stream map

0 views • 23 slides

How Lean Principles are Revolutionizing Product Development

Lean product development is based on the principles of Lean manufacturing, a methodology originally pioneered by Toyota in the automotive industry.

0 views • 3 slides

Lean Oil Absorption Process in Gas Processing

The Lean Oil Absorption process in gas processing involves using hydrocarbon-rich lean oil to absorb heavier hydrocarbons from natural gas, allowing for increased gas condensate recovery. This method is a cost-effective way to separate different products in natural gas, alongside refrigeration proce

1 views • 14 slides

Understanding Job Order Cost Flow in Manufacturing

Job costing in manufacturing involves assigning manufacturing costs to work in process through debits to work in process inventory and credits to raw materials inventory, factory labor, and manufacturing overhead. Job cost sheets are used to record costs chargeable to specific jobs, acting as a subs

2 views • 44 slides

Lean on Me - Backing Track Performance with Inspiring Lyrics

An emotional backing track performance of "Lean on Me" that captures the essence of support and friendship through touching lyrics. The song reminds us of the importance of being there for one another during difficult times, emphasizing the power of unity and empathy. The heartfelt message resonates

0 views • 11 slides

Maximizing Workforce Pipeline Resources Through Lean Coffee Concept

Explore best practices for maximizing workforce pipeline resources through interactive exercises like Lean Coffee meetings. Learn how other cities and companies optimize their workforce pipelines and identify organizations to emulate in Vermilion County. Engage in discussions, quick thinking, and de

0 views • 7 slides

Assessment of Lean Manufacturing in Palestinian Dairy Industry

This project focuses on evaluating the implementation of lean manufacturing concepts in the Palestinian dairy industry. It aims to provide a framework for enhancing lean practices and achieving clear gap analysis. The methodology includes selecting lean tools suitable for the local dairy industry, r

0 views • 36 slides

Perspectives on Lean Production in Social Sciences

Lean production in the social sciences is explored through various perspectives including hard and soft aspects, sociological viewpoints, socio-technical theory, diffusion of lean production, and critical approaches. The discussion covers elements such as industrial engineering, teamwork, societal i

0 views • 11 slides

Understanding Different Types of Production Processes

Explore the various types of production processes, including high-performance manufacturing, continuous production, intermittent production, custom production, discrete manufacturing, and process manufacturing. Learn about the differences between light and heavy assembly in manufacturing. This cours

0 views • 11 slides

Lean Six Sigma Methodology for Business Excellence

Lean Six Sigma methodology offers a strategic approach to optimize business processes, reduce costs, enhance quality, and improve customer satisfaction. This efficient methodology focuses on eliminating waste and defects to drive revenue growth and profitability for organizations. With a background

0 views • 27 slides

Comprehensive Manufacturing Skills Pathways and Training Programs

Explore a range of manufacturing skills pathways including Manufacturing Technician, Production, Machining, CNC Machining, and more. Gain expertise in electrical systems, mechanical fabrication, CNC machining, Lean principles, quality assurance, PLC, and more through online training modules. Develop

0 views • 13 slides

QuaLex Manufacturing: Providing Solutions to Complex Problems

QuaLex Manufacturing is a leading company specializing in sheet metal manufacturing and machining services. With multiple locations and a dedicated team of over 450 skilled employees, QuaLex offers a wide range of fabrication capabilities, equipment listings, and finishing capabilities. Their proven

0 views • 11 slides

Understanding Manufacturing Processes and Industries

Explore the world of manufacturing with insights into the definition, types of manufacturing, economic aspects, industries, and production strategies. Learn about the transformation of raw materials into valuable products, the role of technology in manufacturing, and different types of industries in

0 views • 17 slides

Advanced Manufacturing Career Awareness Guide

This program, funded by the Connecticut Advanced Manufacturing Initiative, aims to debunk myths surrounding manufacturing jobs, highlight career growth opportunities in Connecticut and nationally, emphasize women's roles in manufacturing, and promote Advanced Manufacturing programs in Connecticut co

0 views • 10 slides

Cedar Works Companywide Lean Manufacturing Development Details

The document provides insights into Cedar Works' journey towards lean manufacturing, focusing on the challenges they faced, their training programs, and the objectives they aimed to achieve. It highlights their commitment to embracing lean principles to enhance production systems and meet the demand

0 views • 10 slides

Enhancing Local Bottle Manufacturing through Lean Principles and Simulation

This study focuses on improving a local bottle manufacturing operation by implementing Lean principles and discrete event simulation. It addresses challenges in the industry, presents a case study of an SME bottle manufacturer, and explores opportunities for enhancement through computer simulation u

0 views • 17 slides

Enhancing Healthcare Efficiency Through Lean Six Sigma Principles

Explore the impact of external forces on the healthcare environment and learn about Lean Six Sigma methodologies. Discover how Lean and Six Sigma aim to reduce waste, improve quality, and enhance patient satisfaction by focusing on process efficiency and effectiveness. Dive into the eight forms of w

0 views • 33 slides

Lean Six Sigma in Human Resources: A Comprehensive Overview

Explore the history and evolution of Lean Six Sigma, its methodology, success factors, and application to HR. Gain insights into real-world examples and a case study from New York ISO, presented by David Duda with over 12 years of experience in Lean Six Sigma. Discover how Lean Six Sigma enhances qu

0 views • 33 slides

Understanding Lean TQM (Total Quality Management) in Manufacturing

Lean TQM, originating post-WWII in Japan with Toyota's TPS, focuses on waste reduction, value creation, and continuous improvement in manufacturing processes. Key concepts include Kanban for visual progress tracking and eliminating Muda (waste) and Muri (overburden) to enhance productivity and effic

0 views • 12 slides

How to Manage a Lean Program

Learn how to effectively manage a Lean program with insights on workshop agendas, management tips, staff structure, Empire Belt selection, on-boarding, project succession, and program visibility. Discover key elements like executive support, resource allocation, community building, and continuous im

0 views • 11 slides

Refresher on Lean Process and Vision for Program 232

Lean thinking aims to provide the most value with the fewest resources by eliminating waste, standardizing processes, and continuously improving. The process involves developing standardized work, visual management, and seeking better solutions. Benefits of lean include improved morale, cost reducti

0 views • 10 slides

Understanding the Lean Startup Approach

Lean Startup is a business development approach applying Lean Production to innovation. It emphasizes building, testing, and iterating products efficiently. The methodology focuses on validating learning, measuring progress, and implementing innovative accounting techniques to drive growth. By break

0 views • 35 slides

Lean for Executives & Managers Workshop

Structured approach to maximizing customer value while minimizing waste. Learn about Lean principles, management tools, 8 wastes, and why Lean is important for organizations. Discover how Lean can improve performance, resource management, and corporate culture.

0 views • 12 slides

Evolution of Lean Thinking and Its Impact on Business Practices

Explore the evolution of lean thinking from its origins to modern-day applications, discussing its impact on business practices. Covering topics such as critical analysis, lean vocabulary, application in services, and lean management and leadership, this comprehensive assessment delves into the dept

0 views • 14 slides

Using LEAN & Stepped Care Process Methodology to Reduce Wait Times for Counselling Service

This presentation discusses the successful implementation of Lean and Stepped Care methodologies to reduce wait times for counseling services. The case study presented outlines the journey from identifying the problem to implementing solutions and measuring outcomes. By focusing on Lean values and a

0 views • 34 slides

Collaboration and Lean for Enhanced Productivity in Construction Industry

Explore the symbiotic relationship between collaboration and Lean principles in enhancing productivity in the construction industry. Learn how BAM Nuttall and ISO44001 certification align values, objectives, and processes to drive value creation and predictable performance. Discover the key principl

0 views • 9 slides

Dive into Manufacturing with Tim Christensen, Manufacturing Engineer at The Boeing Company

Explore the exciting journey of Tim Christensen, a manufacturing engineer at Boeing, as he shares insights into his career highlights, passion for problem-solving, and the intricate processes behind manufacturing airplanes. Discover the importance of engineering skills in realizing innovative ideas

0 views • 9 slides

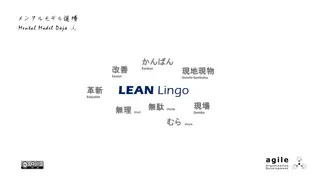

Introduction to Lean Methodology and Tools for Process Improvement

Lean methodology focuses on identifying and eliminating waste in operations to improve efficiency. Key tools such as Kaizen, 5 Whys, Fishbone Diagram, and Spaghetti Diagram are utilized for continuous improvement. The building blocks of Lean include Kaizen, Pull/Kanban, TPM, 5S System, and more. Und

0 views • 8 slides

Lean Manufacturing Project Requirements and Scope

This project involves designing a lean manufacturing implementation in your company/department to evaluate possible improvements and prepare for lean tool implementation. The objective is to understand and implement lean tools effectively for workplace enhancements. The project includes research, cr

0 views • 5 slides

Understanding Lean Manufacturing: A Comprehensive Overview

Lean Manufacturing, characterized by the continuous elimination of waste in the production process, aims to improve efficiency, reduce costs, and enhance productivity. Originating from concepts like Flow Production in 1913 and later developed by Toyota, Lean Manufacturing focuses on minimizing non-v

0 views • 17 slides

Lean In Circle Introductory Meeting Agenda and Key Themes

Discover the structure and focus of a Lean In circle introductory meeting through welcome activities, introductions, discussions on key themes like work-life balance and peer support, and wrapping up with individual and collective goal setting. Learn about Lean In circles, their structure, and the b

0 views • 7 slides