Introduction to Lean Methodology and Tools for Process Improvement

Lean methodology focuses on identifying and eliminating waste in operations to improve efficiency. Key tools such as Kaizen, 5 Whys, Fishbone Diagram, and Spaghetti Diagram are utilized for continuous improvement. The building blocks of Lean include Kaizen, Pull/Kanban, TPM, 5S System, and more. Understanding these concepts is essential for implementing Lean manufacturing practices successfully.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

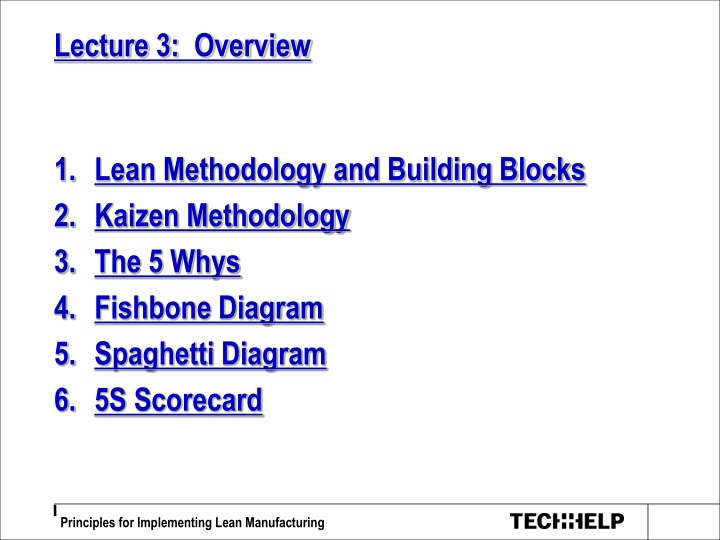

Lecture 3: Overview 1. Lean Methodology and Building Blocks 2. Kaizen Methodology 3. The 5 Whys 4. Fishbone Diagram 5. Spaghetti Diagram 6. 5S Scorecard Principles for Implementing Lean Manufacturing

Definition of Lean A systematic approach to identifying and eliminating waste (non-value-added activities) in a company s operations. Lean emphasizes flowing the product at the pull of the customer. Lean is implemented through both rapid andcontinuous improvement. Kaizen- kai means little or ongoing . Zen means for the better or good. Small continuous improvements on everyone s part leads to world class manufacturing. Principles for Implementing Lean Manufacturing

Lean Building Blocks KAIZEN Pull/Kanban Cellular/Flow TPM Quality at Source POUS Quick Changeover Standardized Work Batch Reduction Teams Value Stream Mapping 5S System Visual Plant Layout Principles for Implementing Lean Manufacturing

Kaizen Methodology 1. Select project/opportunity 2. Study design principles/best practices from previous projects 3. Prepare an analysis of the current state 4. Generate proposed solutions (future state) 5. Develop proposed solution 6. Get feedback on proposed solution 7. Revise and implement solution 8. Measure impact 9. Disseminate

5 Whys Question asking method used to discover root cause of a problem Highlights cause effect relationship Identify problems not just symptoms Have to ask the right why questions Could be any number of whys Example: My car will not start. (the problem) Why? - The battery is dead. (first why) Why? - The alternator is not functioning. (second why) Why? - The alternator belt has broken. (third why) Why? - The alternator belt was well beyond its useful service life and has never been replaced. (fourth why) Why? - I have not been maintaining my car according to the recommended service schedule. (fifth why, root cause) Excerpt from Wikipedia

Fishbone (Ishikawa) Diagram A cause and effect diagram that highlights the relationships and types of causes Image from Wikipedia Example: http://www.techrepublic.com/article/use-a-fishbone-diagram-to-help-attack-complex-problems/

Spaghetti Diagram Chart that shows the flow of product highlights inefficiencies in layout Ship QC Rec Raw Stock QC Screw Machine Shear Stamp Lathe Drill Assembly Brake Mill Weld Grind Finish Parts Stock

5S Scorecard Checklist to evaluate current status of 5S application and guide future application of 5S http://www.slideshare.net/bengeck/5saudit scorecard https://kalispellchamber.files.wordpress.c om/2009/03/office-5s-scorecard- preferred.pdf http://www.leanhealthcareexchange.com. php5-16.dfw1-1.websitetestlink.com/wp- content/uploads/2009/08/5S- Scorecard.pdf