Zero Defects Philosophy in Quality Management

Zero Defects Philosophy is a key principle in Total Quality Management, advocating for perfection in products and processes by eliminating defects completely. Philip Crosby popularized this concept, emphasizing that defects are never acceptable. Key concepts include "Quality is Free" and "Do It Righ

0 views • 19 slides

Lithium-ion Battery Fire Risks and Safety Measures

Lithium-ion batteries pose significant fire hazards due to factors like flammable materials, manufacturing defects, and charging accidents. The frequent incidents of battery fires in various industries highlight the pressing need for improved safety measures. Current solutions, though existing, are

1 views • 12 slides

Software Engineering and Architecture

Reliability in software systems is crucial, as defects can lead to failures impacting reliability. The number of defects directly affects the system's reliability. Not all defects are equal, so prioritizing defect correction based on return on investment is essential. Testing thoroughly, especially

1 views • 40 slides

Raise Awareness for World Birth Defects Day 2024 with WBDD Toolkit

World Birth Defects Day (WBDD) on March 3rd aims to spread awareness and improve care for individuals with birth defects. The WBDD 2024 Toolkit provides resources, challenges, and suggested activities to help you participate and raise awareness. Join the movement by sharing your story and advocating

6 views • 15 slides

Understanding the Manufacturing Process of aluminum casting parts

Aluminum casting is a widely used manufacturing process in various industries, including automotive, aerospace, construction, and electronics. It involves pouring molten aluminum into a mold to produce a desired shape or part.

2 views • 5 slides

Permanent-Mold Die Casting Processes Overview

Permanent-mold die casting is a process where molten metal is injected into a mold cavity under high pressure, maintained during solidification. This process utilizes hot-chamber and cold-chamber die casting machines for casting various metals like zinc, aluminum, brass, and magnesium. Hot-chamber m

4 views • 7 slides

Understanding Patterns in Casting Process

Patterns play a crucial role in the casting process by creating replicas of objects with modifications, such as pattern allowances and core prints. They help in forming mold cavities, reducing casting defects, and minimizing costs. Various materials like wood, metal, and plastics are used for patter

1 views • 15 slides

Ensuring Reliability of Deep Neural Network Architectures

This study focuses on assuring the reliability of deep neural network architectures against numerical defects, highlighting the importance of addressing issues that lead to unreliable outputs such as NaN or inf. The research emphasizes the widespread and disastrous consequences of numerical defects

0 views • 26 slides

Casting Net, livebait

Here is the world\u2019s best cast net in the USA. When you catch bait well, you will catch more fish. We have different type of casting nets for different depth and expertise. \/\/livebait.com\/

2 views • 3 slides

Foundry Technology Unit 4: Gating and Risering System Overview

In Unit 4 of Foundry Technology, the focus is on Gating System, Risering System, and Quality Control in Foundry. The content covers components of the gating system, considerations for defect-free casting, proper design requirements, and factors affecting the functioning of the gating system. Key top

1 views • 94 slides

Overview of Casting Alloys: Ferrous and Nonferrous Options

Commercial castings are predominantly made from alloys rather than pure metals for better properties and casting ease. Ferrous casting alloys include cast iron and steel, each with unique characteristics and challenges. On the nonferrous side, aluminum, copper alloys, and zinc alloys offer various b

0 views • 15 slides

Understanding Yarn Manufacturing: Processes and Defects in Drafting Zone

Yarn manufacturing involves various processes like drawing, doubling, and drafting to improve fiber alignment and quality. Defects in the drafting zone such as roller slip and drafting wave can impact the yarn production process. Roller setting plays a crucial role in maintaining the correct nip-to-

1 views • 19 slides

Common Damages in Machine Parts and Bearings

Sliding bearings and anti-friction bearings in machinery often experience wear, fatigue, and various damages due to factors like lubrication, alignment, and applied loads. The process of wear is influenced by wear velocity, operation conditions, and foreign substances, leading to overheating and cha

0 views • 34 slides

Understanding Solidification Process in Metal Casting

Solidification in metal casting involves nucleation and growth processes, impacting the final product's quality. Factors such as type of metal, thermal properties, and mold shape influence solidification. Homogeneous nucleation occurs below the equilibrium freezing point, while heterogeneous nucleat

1 views • 8 slides

Understanding Title Defects in Real Estate Closings

Marketable title signifies a clear ownership chain, insurable title allows for insurance coverage against known defects, while apparent and real breaks in title require different resolutions to ensure a property's marketability. Dealing with title defects is crucial in real estate transactions to sa

0 views • 14 slides

Common Casting Defects in Prosthodontics: Causes and Prevention

Casting defects in prosthodontics can result from errors in the casting procedure, leading to issues like distortion, surface roughness, porosity, and incomplete detail. Various causes such as stress relaxation during wax pattern preparation can contribute to distortion, while factors like air bubbl

5 views • 27 slides

Metal Alloys Forming Operations: Forging, Casting, and More

Metal alloys undergo forming operations like forging, rolling, extrusion, and casting to change their shape through plastic deformation. Hot working and cold working processes are utilized to enhance mechanical properties. Techniques such as sand casting, die casting, and investment casting are empl

0 views • 18 slides

Understanding Cream Defects: Causes, Prevention, and Interpretation

Dive into the world of cream defects with insights from Dr. Sanjeev Kumar, an Associate Professor in Dairy Technology. Explore the relation between microbiological quality and interpretation results, understand flavor defects in market cream, and learn about miscellaneous defects like feathering in

0 views • 10 slides

Adjunctive Role of Orthodontic Therapy: Benefits and Applications

Orthodontic therapy plays a crucial role in improving periodontal and osseous defects in adult patients, along with aiding in restorative treatments like implant placement and tooth restoration. This treatment modality can align crowded anterior teeth, reposition teeth to correct defects, and enhanc

0 views • 34 slides

Understanding Casting Defects in Metal Casting Processes

A casting defect is an undesirable irregularity in metal casting processes that may require correction or elimination. This article discusses the definition, types, remedies, causes, prevention, and conclusion of casting defects. It covers shrinkage defects, gas porosity, pouring metal defects, meta

0 views • 21 slides

Investment Casting Process: A Detailed Step-by-Step Guide

Investment casting process involves creating a wax pattern, assembling the pattern onto a sprue, coating with ceramic layers, de-waxing and firing, casting molten metal, knockout, finishing, testing, inspection, packing, and shipping. This detailed guide provides insights into each step of the inves

0 views • 10 slides

Studies on Defects in ZnO Nanowires and Their Impact on Properties

In this research, various aspects of defects in ZnO nanowires are explored, including their formation through heating and ion bombardment, as well as the role of contacts. The investigation delves into the growth, control, and motivation of defects, showcasing the effects of processes like argon bom

0 views • 8 slides

Fly Fishers International: Preserving Fly Fishing Legacy and Conservation Efforts

Fly Fishers International is an international non-profit organization dedicated to supporting, enhancing, and preserving fly fishing opportunities through environmental stewardship, education, and conservation efforts. With a history dating back to the 1960s, they focus on educating individuals in c

0 views • 28 slides

Manufacturing and Finishing Techniques of Plastic Products

Learn about various manufacturing processes of plastic products including casting, compression molding, transfer molding, and more. Explore the production of PMMA sheets through cell casting and other methods. Discover the intricacies of finishing and decorating plastic products with operations like

0 views • 39 slides

Comprehensive Guide to Casting and Splinting in Orthopedics

This comprehensive guide covers the essential aspects of casting and splinting in orthopedics, including their role in supporting and protecting orthopedic injuries, techniques for immobilizing fractures and sprains, conditions that benefit from casts and splints, possible complications to watch for

0 views • 9 slides

Understanding Ray Tracing Techniques in Computer Graphics

Explore the fundamentals of ray tracing including recursive ray casting, ray casting vs. ray tracing, basic algorithms, shadows, reflections, refractions, and advanced illumination models like Whitted model and OpenGL's illumination model. Learn about casting rays from the eye, handling reflections

0 views • 50 slides

Understanding Software Defect Management

Defects in software arise from various causes such as miscommunication, lack of experience, human factors, and poor testing skills. Different types of defects can be classified based on severity, work product, type of error, and status. Severity-wise classification includes major, minor, and fatal d

0 views • 30 slides

Understanding Birth Defects: An Overview of Congenital Anomalies

Birth defects refer to abnormalities present in babies at birth, regardless of genetic or prenatal causes. They affect 2-3% of babies in the US, making them a leading cause of infant mortality. Structural defects like cleft lip/palate, spina bifida, and club foot can impact a child's health and deve

0 views • 17 slides

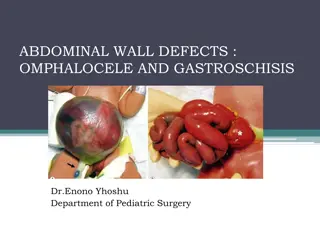

Abdominal Wall Defects: Omphalocele and Gastroschisis Overview

Abdominal wall defects such as omphalocele and gastroschisis are congenital conditions where abdominal organs protrude through an unusual opening in the abdomen. These defects result from disruptions during embryonic development, leading to serious implications for affected individuals. Different ty

1 views • 42 slides

Matrix Measurements and Analysis After First Metal Workshop

The pilot run matrix measurements were conducted following the 7th Belle II VXD workshop and the 18th International Workshop on DEPFET Detectors and Applications by Rainer H. Richter and Paola Avella for the MPP/HLL team. The measurements included assessing defects, diode integrity, metal shorts, an

0 views • 30 slides

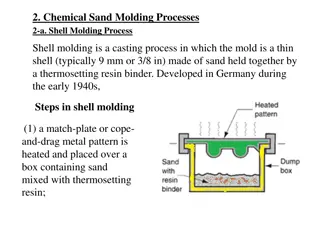

Overview of Shell and Sodium Silicate Molding Processes in Casting

Shell molding is a casting process involving a thin sand shell held together by a resin binder, offering advantages like smoother mold cavity surfaces and good dimensional accuracy. However, it can be costly for small quantities. Sodium Silicate Molding Process involves coating refractory materials

0 views • 19 slides

Gaussian Processes for Treatment of Model Defects in Nuclear Data Evaluations

Gaussian Processes (GP) are explored for treating model defects in nuclear data evaluations. The presentation discusses the impact of model defects on evaluation results and proposes using GP to address these issues. The concept of GP and its application in treating model defects are detailed, highl

0 views • 28 slides

Understanding Classification of Discontinuities in Metal Processing

Classification of discontinuities in metal processing involves identifying interruptions in the normal physical structure, such as cracks, seams, and inclusions, which may or may not be defects. Discontinuities can be surface or subsurface, with surface ones being more likely harmful. The origins of

0 views • 29 slides

Casting Inspection Methods and Techniques

Various methods such as visual inspection, sound test, impact test, pressure test, radiography, and magnetic particle testing are used for inspecting castings to detect defects like blow holes, cracks, mismatches, and discontinuities. Each method serves a specific purpose in evaluating the quality o

0 views • 15 slides

Metal Cast Restorations in Conservative Dentistry & Endodontics

This presentation focuses on metal cast restorations, covering topics such as indications and contraindications, principles of tooth preparation, steps involved, modifications, additional retention methods, casting defects, primary and secondary retention forms, luting cements, grooves, and more. Th

0 views • 24 slides

Best Casting Net, livebait

Here is the world\u2019s best cast net in the USA. When you catch bait well, you will catch more fish. We have different type of casting nets for different depth and expertise. \/\/livebait.com\/

2 views • 3 slides

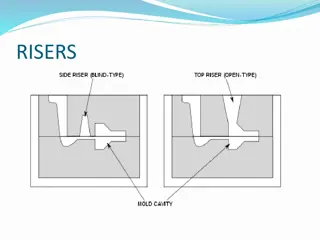

Understanding Risers and Casting Defects in Metal Casting Process

Risers are crucial in reducing shrinkage problems during casting by promoting directional solidification. Open versus blind risers have distinct characteristics affecting feeding and positioning within the mold. Rapid cooling rate and use of insulating compounds impact the efficiency of casting, whi

0 views • 41 slides

Understanding Aluminium Sand Casting Process

Aluminium sand casting is a cost-effective process commonly used in schools due to its affordability and achievable casting temperature. The process involves pattern making, moulding, pouring molten metal, removing sand, and cleaning the final workpiece. Quality patterns and moulds are crucial for s

0 views • 10 slides

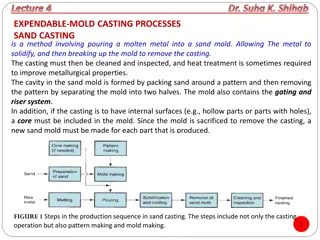

Expendable-Mold Casting Processes in Sand Casting: Lecture Insights

Sand casting is a process wherein molten metal is poured into a sand mold, left to solidify, and then the mold is broken to retrieve the casting. This casting method involves pattern making, mold creation, and uses a gating and riser system for complex geometries. Riser design is crucial in managing

0 views • 9 slides

Overview of Metal and Sand Casting Processes

Metal and sand casting are ancient manufacturing techniques dating back to 4000 B.C., allowing the production of complex shapes in various metals. The casting industry produces millions of kilograms of castings annually, primarily using materials like gray iron, ductile iron, aluminum alloys, and co

0 views • 13 slides