Hybrid ECO Detailed Placement Flow for Improved Reduction of Dynamic IR Drop

A study on dynamic IR drop challenges in 7nm technologies, proposing a hybrid detailed placement flow to reduce peak demand currents and improve voltage drop. The approach involves ILP formulation, clip generation, and experimentation to achieve significant reductions in dynamic voltage drop with enhanced scalability and runtime efficiency.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

A Hybrid ECO Detailed Placement Flow for Improved Reduction of Dynamic IR Drop Andrew B. Kahng1,2, Bodhisatta Pramanik2 and Mingyu Woo2 1Department of Computer Science and Engineering, University of California, San Diego 2Department of Electrical and Computer Engineering, University of California, San Diego

Outline Introduction Motivation Problem statement & contribution Linearity of the demand current waveform Our approach: Proposed hybrid flow Clip generation ILP formulation Experimental setup and results Conclusion and future goals 2

Motivation Static vs. dynamic IR drop Discrepancy between static vs. dynamic IR drop Dynamic IR drop is challenging for 7nm technologies Higher IR drop on cell larger cell delay at the timing sign-off Huang et al. [7] introduces thelinearity of demand current Proposes two levels of integer linear programming (ILP) based detailed placement methodology Limitation: (1) Longer runtime. (2) Two-level ILP IR Drop Cell delay Cell Delay (s) Static IR Drop 7nm aes_cipher_top Dynamic IR Drop VDD (V) [7] Huang et al., Dynamic IR-Drop ECO Optimization by Cell Movement with Current Waveform Staggering and Machine Learning Guidance , Proc. ICCAD, 2020, pp. 1-9. 3

Problem statement & contribution Given: (i) post route-opt design, (ii) current waveforms from all instances Find: new legalized placement that reduces the peak demand currents for every power and ground rail Our Contribution: (i) ILP-based detailed placer that can be used at the post-route opt (PRO) stage (ii) To enhance scalability, we extract clips and formulate an ILP problem to minimize cell displacement and maximum peak currents for each power and ground rail (iii) Our proposed approach is designed to integrate seamlessly with existing ECO detailed placement flow (iv) Our hybrid approach achieves up to 15.3% reduction in dynamic voltage drop compared to conventional flows, with less displacement, better timing quality and 55.1% less runtime 4

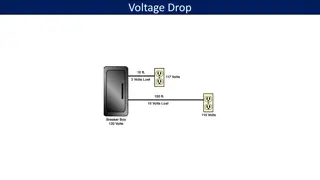

Linearity of the demand current waveform Suppose there are three instances Three waveforms are given *Assumption VDD1 I-I1 I-I2 I-I3 1 2 m < n < 2*m Instance Current at VDD pins n m m VSS1 t t t 3 t1 t1 t2 VDD2 Suppose inst 2 will be moved from the 1st to the 2nd row I-VDD1 I-VDD1 VDD1 Lower Drop 2*m 1 2 Higher Drop m Peak currents reduced!!! (2*m, n) (m,n) t t After Swap t1 VSS1 t1 I-VDD2 I-VDD2 3 2 n n VDD2 t t t1 t2 t2 5

Outline Introduction Motivation Problem statement & contribution Linearity of the demand current waveform Our approach: Proposed hybrid flow Clip generation ILP formulation Experimental setup and results Conclusion and future goals 6

Our approach: proposed hybrid flow Conventional: (C+C) Commercial ECO DP 1 Commercial ECO DP 2 Our hybrid flow: (O+C) Our ILP DP Commercial ECO DP *DP = Detailed placement Post-Route Opt (PRO) P&R Database Commercial Flow Our Hybrid Flow O C Measure IR Drop Measure IR Drop Clip Generation Our ILP DP Comm DP 1 ECO Detailed Placement ILP Detailed Placement ECO Route ECO Route C Measure IR Drop C Measure IR Drop ECO Detailed Placement ECO Detailed Placement Comm DP 2 Comm DP ECO Route ECO Route 7

Clip generation Clip: an extracted window from the original layout Improves the scalability of ILP runtime PDN Zone: adjacent power and ground connections independent IR drops Clip overlap violations: Do not allow geometric y-axis overlap within the same PDN zone Our Hybrid Flow Measure IR Drop Clip Generation ILP Detailed Placement ECO Route Measure IR Drop ECO Detailed Placement ECO Route PDN PDN PDN Contacts Contacts Contacts violated No violations IR drop heatmap 7nm mpeg2_top PDN Zone clip Clip overlap violations 8

ILP formulation Objective Our Hybrid Flow Measure IR Drop Clip Generation ILP Detailed Placement ECO Route IR Drop [10] Measure IR Drop : Objective by definition ECO Detailed Placement ECO Route : Maximum peak currents at power rail : Maximum peak currents at ground rail Waveform Background Noise Placement Displacement Legalization baseline [10] Disp Placement : By definition : At most one placement per site : Row swap limitation : Always one placement per cell Placement Rowswap Create ?? ? only when ?? to improve scalability ? maxDisp 9 [10] Li et al., Mixed Integer Programming Models for Detailed Placement , Proc. ISPD, 2012, pp. 87 94.

Outline Introduction Motivation Problem statement & contribution Linearity of the demand current waveform Our approach: Proposed hybrid flow Clip generation ILP formulation Experimental setup and results Conclusion and future goals 10

Experimental results benchmarks and setups Total 10 designs for our experiments (7? ?? ? FinFET) ILP Solver: IBM ILOG CPlex 12.10 Server: Intel Xeon(R) Gold 6148, 2.40GHz (40 cores) CPU and 256GB Synthesis: Synopsys Design Compiler R-2020.09 P&R, EcoRoute: Cadence Innovus v21.11-s130_1 IR Drop Sim: Cadence Voltus v21.14-s111_1, 7ns for timestamp ILP Parameters: Clip Size: 1.4 m by 1.2 m ? and ?: 1012 and 1 Row Limit: 5 maxDisp: 0.25 m Total 10 designs used for our evaluation 11

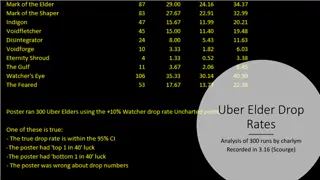

*DVD: Dynamic voltage drop Experimental results dynamic IR Drop (worst DVD) C: Commercial ECO DP O: Our ILP DP QoR comparison for worst DVD Worst DVD *Bold: Best Avg. Top 5 Worst DVDs Avg. Top 10 Worst DVDs C C+C O O+C C C+C O O+C C C+C O O+C 5 8 1 16 5 7 1 17 Best Count 5 9 1 15 Achieved up to 15.3% less effective DVD 12

Experimental results displacement comparison Displacement(um) comparison Conventional Our Proposed Design Thresholds C C+C O O+C aes2 65 1935.996 2842.872 37.728 2188.38 des2 65 536.754 745.302 36.81 571.134 jpeg2 65 3015.366 4063.86 96.678 3046.194 mpeg2 65 856.392 1255.536 21.024 850.53 vga2 65 2606.238 3365.496 79.578 2604.69 AVERAGE (All thresholds) 885.9 1234.8 29.01 898.7 Displacement Comparison: O < C < O+C < C+C Our proposed methods have less displacements 13

Experimental results runtime comparison Runtime(s) comparison Conventional Our Proposed Design Thresholds C C+C O O+C aes2 65 109 219 35 181 des2 65 152 500 18 175 jpeg2 65 421 783 25 375 mpeg2 65 157 324 19 180 vga2 65 539 1089 20 114 AVERAGE (All thresholds) 292 599 15 269 Displacement Comparison: O < C < O+C < C+C Our proposed methods have less displacements Runtime Comparison: O < O+C <C < C+C Our proposed methods have less runtime 14

Experimental results DP outcome (timing) QoR comparison for timing *Bold: Best O O+C NFE C+C NFE C NFE NFE 5.77 35.20 43.20 37.63 Average NFE Comparison: O < C < O+C < C+C Within reasonable range Our proposed methods have less NFE *WNS(W): worst negative slack *TNS(T): total negative slack *NFE(N): number of failing endpoints O+C outperformed DVD, displacement, runtime and timing!!! compared to two serial ECO DPs (C+C) 15

Outline Introduction Motivation Problem statement & contribution Linearity of the demand current waveform Our approach: Proposed hybrid flow Clip generation ILP formulation Experimental setup and results Conclusion and future goals 16

Conclusions and future goals Our hybrid flow successfully reduces dynamic IR drop Reduced worst dynamic voltage drops (DVD) Followed by commercial EDA detailed placement optimization ILP formulation for ECO detailed placement Simultaneously optimizes IR drop and displacement within each clip Propose maxDisp to control the scalability Achieved better QoR Reduced worst dynamic voltage drop by up to 15.3% 55.1% less runtime compared to conventional flow Less timing violations (NFE) on average Future works Eliminates the need for hybrid approaches Gaining a stronger understanding of commercial ECO DP flow 17