Ship Structural Framing Systems in Nautical Science

Understanding ship structural framing systems is crucial in naval architecture. The text explores transverse and longitudinal framing systems, discussing their advantages, disadvantages, and contributions to ship strength. It highlights how these systems help in overcoming various stresses on a ship hull and the importance of proper reinforcement to ensure structural integrity and efficiency.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Unit-1 Frames, Beams, Watertight bulkhead, shell and deck plating B.Sc Nautical Science Naval Architecture -III

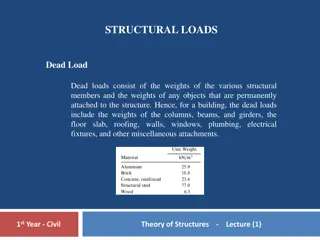

Stresses on Ship Hull Vertical Shear Longitudinal bending Transverse stress Combination stress

Strengthening of ship structure We can conclude from previous discussion, that a ship has to overcome with many stresses all together strengthened. For that framing system is adopted, Transverse Framing system Longitudinal Framing System Combined framing system to be structurally

Transverse Framing System This type of framing system is generally adapted in small vessels and ships which are basically operating in calm waters Since wave bending of ship is not happening in such ships transverse strengthening will be more efficient. Longitudinal deck girders support the transverse deck beams Longitudinal strength in a transversely framed ship is provided by : The centre girder, the shell plating and inner bottom plating By a number of large, widely spaced longitudinal members e.g. longitudinal deck girders.

Transverse Framing system Disadvantages Vertical support for decks requires more closely spaced transverse bulkheads(hence smaller compartments) or Pillars (stanchions) or Longitudinal Bulkheads Advantages Open, nearly rectangular interior space Ideal for stowing large, irregular, break-bulk items or Vehicle(RO-RO)

Transverse Side Longitudinal girders Centre girders Deck longitudinals

Longitudinal Framing System All the ship s secondary supporting members are fitted the longitudinal direction and are known as longitudinals. Side shell longitudinal are called as stringers The system consists of many small, closely spaced longitudinals supporting the plating directly and being supported in turn by a few largely spaced transverses. They also contribute to the longitudinal strength of the ship, making the longitudinal framing system more structurally efficient than the transverse system.

Stringers Bulkheads

Longitudinal Framing system Disadvantages No large, open interior spaces Difficult to load or unload break-bulk items Difficult to stow large, irregular shaped items. Advantages Widely spaced transverse bulkheads allow for large (i.e. long ) continous cargo spaces ( tanks ) Ideal for stowing liquids (reduced free surface effects)

Beams & Beam Knees(stiffener brackets) Beam is a strength member to give strength to the ship plating or deck in the transverse direction Beam knees are the junction at which the frames connect the beams Typically an I section. Brackets gives connection to the longitudinals and

Water tight Bulkheads A watertight bulkhead is a transverse bulkhead mounted on the tank top and it must extend right to the uppermost continuous deck. Watertight bulkheads are installed to: Divide the ship into watertight compartments and thereby limit flooding if the hull plating is damaged; Improve the transverse strength of the structure; Prevent distortion of the hull plating; Support the deck girders and longitudinal; Rigidly attach the tank top to the upper deck; Greatly slow the spread of fire.

Water tight Bulkheads Transvers Bulkhead Corrugations can be vertical or horizontal. Longitudinal bulkhead must be horizontal Corrugations. Lighter scantlings are installed around Machinery space since they do not Contribute to strength of ship

Forward section of ship including bulkhead

SHELL EXPANSION AND NUMBERING OF PLATE

SHELL EXPANSION AND NUMBERING OF PLATE Shell expansion plan : can also be done Lettering from keel strake and up Numbering from aft to forward Outermost strakes on deck