Unit Costing in Industries

Unit costing is a method based on production units and is used in industries with continuous and uniform production of a single product or similar grades. The cost per unit is calculated by dividing the total cost incurred by the number of units produced. Various industries like collieries, quarries, cement works, and breweries utilize unit costing with natural cost units such as tonne of cement or barrel of beer.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

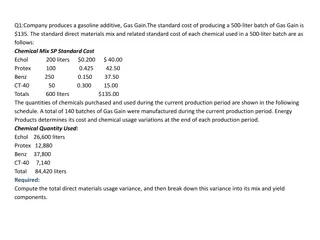

UNIT II UNIT II COSTING UNIT UNIT COSTING

Meaning of unit costing Unit costing is a method of costing based on units of production. It is also known as output or single costing The output is measured in convenient physical units It is a simple method of costing employed in industries where the production is continuous, uniform ans is of only a single product or of essentially one product in two or more grades. Units of output being identical, the costs are measured by a common unit Colleries, quarries, brick works, diaries, breweries, sugar mills, cement works, paper mills and iron foundries are some of the industries employing unit costing

Formula : ????? ???? Cost Per Unit = ??.?? ????? ???????? The unit cost is arrived at by adding the total cost during a period by the number of units produced.

Unit of Cost The industries where unit costing is used, nature of business furnishes a natural cost unit. The following is the list of some of the industries with a natural cost unit: Unit of Cost Industry/ Product Breweries Barrel of Beer dairies Little or gallon of milk Cement Works Tonne of Cement Brick works per 100 or 1000 Bricks Quarries Tonne Sugar Mill Tonne of Sugar Colleries Tonne of Coal Automobiles Number Cable Metre Weaving Mill Metre of Cloth

Unit costing is applied in industries where manufacturing methods are simple Industrial organisations producing products like textiles, automobiles, typewriters etc., use unit costing The selection of suitable cost unit in an industry or organisation is very simple The natural unit of measurement in which ultimate production is measured, is being taken as suitable cost unit.

Procedure of Unit Costing Application of unit costing method involves collection and analysis of all costs incurred, treatment of stocks and preparation of cost sheet Steps: Collection of Costs: If unit costing is applied in an enterprise manufacturing a single product, the costs need not be analysed in a greater detail. When a single product is manufactured in two or more grades, the costs should be analysed in a greater detail so as to allocate costs to each one of the grades on suitable basis 1. - -

Cost of Materials: Materials are purchased from time to time against requisitions from the work stores Where only one product or only one type of product is manufactured, the cost of materials consumed can be directly charged to the product Materials consumed can be ascertained on the basis of requisitions. Formula: Cost of Material consumed = opening stock of raw materials + Net Purchases closing stock of raw materials Normal loss of materials can be adjusted by inflating the issue price of materials In case of abnormal loss of raw materials, the loss may be included ynder factory overheads or it may be charged separately to costing Profit and Loss Account a) - - - - - - -

b) Cost of labour: It is necessary to maintain proper payroll accounting for each department A distinction has to be made between direct and indirect labour c) Overheads: Since the costs are ascertained periodically, overheads can be computed with the help of financial records In certain cases where accounts are not received, estimated cost may be considered, as in the case of lighting, gas, power etc. Overheads are classified into three broad categories: factory overheads, office and administration overheads and selling and distribution overheads. Since the financial statements are prepared annually after the year is over, the overheads are estimated on a certain predetermined basis say, as a percentage of prime cost or works cost - - - - - -

Treatment of stocks Stock of Raw Materials: The units produced and sold may not be equal as there may be opening and closing stocks. Hence the problem of valuing opening and closing stock arises Normally stock is valued at cost inclusive of factory overheads Objective of such valuation is to exclude from total costs, all expenses that do not relate to current sales If the opening stock, closing stock, purchases of raw material is given; cost of raw material consumed can be calculated by the following formula: Cost of Material consumed = opening stock of raw materials + Net Purchases closing stock of raw materials 1) - - - - - -

2) Work in Progress: It is the value of partly finished units or the units which are still at the processing stage Work in Progress may be valued either at prime cost or at works cost. Generally, the work-in-progress is valued at works cost a) valuation at prime cost: If the work in progress valued at prime cost, the amount of work in progress is adjusted before working out the prime cost. Formula: Direct materials Add: Direct wages Add: Direct Expenses Add: Opening work in Progress - - - - xx xx xx xx xxx xx xxx Less: Closing work in progress Prime cost

b) Valuation at works cost: If work in progress is valued at work cost, it is adjustd before arriving at the works cost. Formula: Prime Cost Add: Factory overhead Add: opening work in Progress - - xx xx xx xx xx xx Less: Closing work in Progress Work Cost

3. Stock of finished goods: The opening and closing stock of finished goods should be adjusted before calculating cost of finished goods sold Formula: Cost of Production Add: opening stock of finished goods - - xx xx xxx xx xx Less: Closing stock of finished goods Cost of finished goods sold

Treatment of By products, Scraps, and Defectives Scrap is the material remaining at the end of a manufacturing process It is the material that cannot be used for the originally intended purpose It has a realisable value less than its actual cost Amount realised on sale of scrap can be deducted from factory overheads or works cost. In case of by products, their net realisable value or sale value should be deducted either from works cost or from works overheads If some of the units produced are defective, extra cost may be incurred for their rectification. Such extra cost on rectification of defectives is included under factory overheads as an elementary factory cost If it is very high, it may be treated as an abnormal loss and thus excluded from works overheads. Carriage inward : carriage on purchase of materials which should be added to cost of material consumed Carriage outward: it is the carriage on sales which should be treated as selling and distribution overhead

Non-cost items Non-cost items are those items which do not form part of cost of a product. Such items should not be considered while ascertaining cost of a product These items are included in P/L A/C as per the principles of financial accounting Income /Gains: transfer fees, interest received, dividend received, rental income, profit on sale of investments, profit on sale of fixed assets etc. Expenses/Losses: Preliminary expenses w/off, Goodwill w/off, Brokerage on issue of shares, Underwriting Commission, discount on issue of shares/debentures, interest on loans, fines and penalties, loss on sale of fixed assets, loss on sale of investments, interest on capital etc. Appropriations: Provision for Tax, provision for dividend, provision for dividend distribution tax, Transfer to various Reserves.

Cost sheet Meaning For determination of total cost of production, a statement showing the various elements of cost is prepared. This statement is called as a statement of cost or cost sheet Features: It relates to a particular product It relates to cost incurred during a particular period It may show total cost as well as per unit cost It may be based on actual data or estimated data. 1. 2. 3. 4.

Purposes of cost sheet: It gives the break up of total cost under different elements It helps comparison with previous years It facilitates preparation of tenders or quotations. It enables the management to fix up selling price. It controls cost. It shows total cost as well as cost per unit 1. 2. 3. 4. 5. 6.

Division of cost Prime cost: It comprises of all direct materials, direct labour and direct expenses. It is also known as flat cost. Prime cost = Direct Materials + Direct labour + Direct Expenses 2. Works cost: It is also known as factory cost or cost of manufacture. It is the cost of manufacturing an article. It includes prime cost and factory expenses. Works cost = Prime cost + Factory overheads 3. Cost of Production: Cost of Production = Factory cost + Administrative Expenses 4. Total cost: Total cost = cost of production + selling & distribution Expenses 5. Selling Price: Selling Price = Total Cost + Profit (-Loss ) 1. - -

Cost sheet for the period. Particulars Direct Cost Direct Material consumed Direct or Productive Wages Direct Expenses * Prime cost Add: Factory Overheads * Works or Factory Cost Add: Office & Administration Overheads * Cost of Production Add: Opening stock of finished goods Less: Closing stock of finished goods * Cost of Goods sold Add: selling and distribution overheads * Cost of Sales Add: Profit (Loss) * Sales schedule No. Amount 1 2 3 4