Paper Airplanes Production Process and Cost Analysis

Explore the production process and cost accounting for paper airplanes, detailing team roles, materials costs, employee costs, and overhead costs. Understand the sequential process of folding paper airplanes in teams and the critical quality assurance step. Get ready for controlled chaos in managing the production workflow efficiently.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

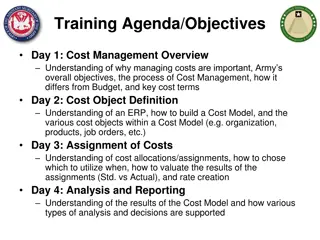

Paper Airplanes and Cost Accounting Team roles Six-person teams have one warehouse supervisor, one accountant, and four folders Five-person teams have one warehouse supervisor, one accountant, and three folders Four-person teams have one warehouse supervisor/accountant and three folders Accounting Data (your accountant will build out the P&L on the whiteboard) $10 sales price per plane $1 cost per sheet of paper (direct materials cost) $10 cost per employee per production period $100 in overhead costs per production period Production process is sequential Each folder completes part of the plane and then hands it down the line to the next folder The last folder also performs quality assurance (it has to fly in order to be sold ) So you need to quickly figure out how you're going to fold your planes and what your handoff steps will be in the folding process! CRITICAL RULE When I say Stop, you must immediately freeze all work on that second!

Just in Case You Don t Know How