Environmental Health and Safety Panel Breakout Meeting Highlights

The Environmental Health and Safety (EH&S) Panel Breakout Meeting held on March 25, 2021, covered various topics including panel updates, injury rates, workers' compensation, environmental concerns, OSHA updates, and COVID-19 control measures. Discussions on injury types, new technology usage, OSHA regulatory inspections, and the impact of COVID-19 were key highlights. The session emphasized ongoing efforts to enhance safety and compliance within shipyards.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

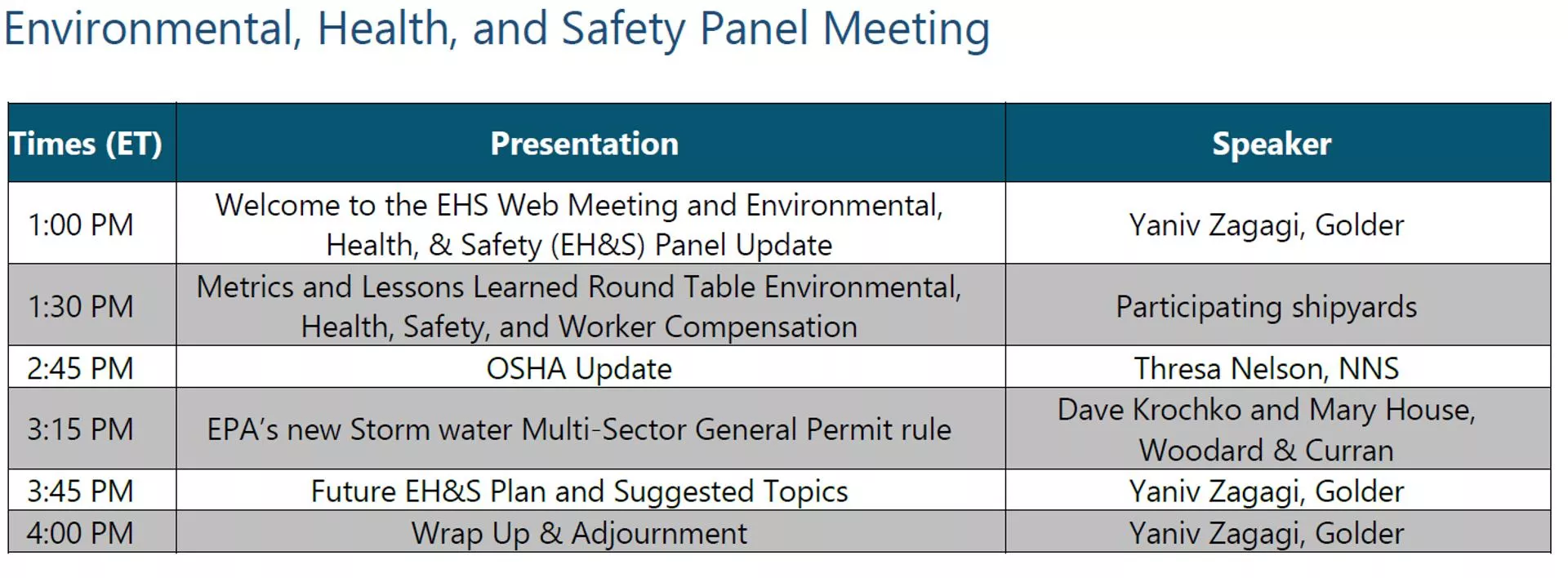

Environmental, Health and Safety Panel Breakout March 25, 2021 Vice Chair: Yaniv Zagagi, Golder Associates Inc. 1

Welcome to the EHS Web Meeting Welcome 2

Environmental, Health, & Safety (EH&S) Panel Update Panel Projects Suspended EH&S Panel Chair Selection of Panel Chair will likely wait until it is closer to the pre- scheduled time the NSRP will hold all the other required panel officer elections. If you want to think about yourself possible nominee, you need to make sure they are from a U.S. private sector shipyard and have the support of the nominee s organization 3

Roundtable Discussion 1.Austal USA 2.BAE Ship Repair 3.Conrad Shipyard 4.General Dynamics Bath Iron Works 5.General Dynamics Electric Boat 6.General Dynamics NASSCO 7.Ingalls Shipbuilding 8.Marinette Marine 9.Newport News Shipbuilding 10.Halter Marine 11.Vigor 4

Injury rates a. Rates: TRIR _____ DART ______ LWDIR _____ b. What are the top three injury types (e.g. falls, cumulative trauma) c. Are the rates up or down from 2019? d. What factors are affecting the injury rates? e. Specific programs or areas of emphasis to reduce injuries (anything unique?) f. Any serious injuries, fatalities or near misses and associated lessons learned? g. Use of any new technology? h. h. Recent fire prevention efforts. Workers Compensation a. Claims up or down? b. What factors are affecting claims? c. Cost? Up/down? Unusual factors influencing cost? d. Any unique claims? e. Any legislative issues of interest? Environmental a. Any reportable releases/events? b. Any NOVs? c. Regulatory inspections? Announced? Unannounced? d. Program improvements? Use of new technology? OSHA Regulatory inspections or visits? a. Any noteworthy citations? b. Any Reportable Injuries? How did OSHA respond to the notification? COVID-19 a. What are the major steps your shipyard takes for COVID-19 control b. Are there any outbreak or lessons learned that you could share?

OSHA Regulatory Agenda Minimal/no significant rulemaking Shipyards should monitor for new administration priorities LOTO 7

OSHA revised beryllium standards for construction, shipyards OSHA has finalized revisions to its beryllium standards for the construction and shipyard industries. Announced Aug. 28, 2020 the final rule includes changes designed to clarify the standards and simplify or improve compliance. The rule, published in the Aug. 31, 2020 Federal Register, amends the following: definitions, hazard communication, housekeeping, medical surveillance, methods of compliance, personal protective clothing and equipment, recordkeeping, and respiratory protection. OSHA removed the hygiene areas and practices paragraph from the standards because the necessary protections are provided by existing OSHA standards for sanitation. These changes set to take effect Sept. 30, 2020 don t affect the permissible exposure limit for beryllium of 0.2 micrograms per cubic meter of air and the short-term exposure limit of 2 micrograms per cubic meter of air. OSHA says it expects the rule to affect about 12,000 workers in nearly 2,800 establishments. 8

Emphasis Programs for Ship Boat Build and Repair National Emphasis Programs COVID-19, DIR 2021-01 (CPL-03) 3/12/2021 OSHA Instruction - CPL 02-02-076 - National Emphasis Program - Hexavalent Chromium - 02/23/2010 Local Emphasis Programs Region 3 - DE, DC, MD, PA, VA, WV 2019-06 (CPL 04) - Regional Emphasis Program for Programmed Maritime Inspections Region 4 - AL, FL, GA, KY, MS, NC, SC, TN CPL 20/04 (CPL 04) - Local Emphasis Program for Ship Boat Build and Repair Region 5 - IL, IN, MI, MN, OH, WI CPL 04-00 (LEP-100) - Emphasis Program for Maritime Industries. Region 9 - AZ, CA, HI, NV, and American Samoa, Guam and Northern Mariana Islands CPL 04-00-05 - Local Emphasis Program (LEP) for Ship and Boat Building and Repair Region 10 - AK, ID, OR, WA 19-05 (CPL 04) - Local Emphasis Program: Shipyard Employment Operations 9

COVID-19 - Updated Interim Enforcement Response Plan OSHA directed by EO to promulgate a Temporary Emergency Standard (ETS) by 15 Mar 2021. Status: As of 23 Mar ETS reportedly in draft and under review 12 Mar 2021, OSHA publishes National Emphasis Program (NEP) for COVID-19, DIR 2021-01 (CPL-03). OSHA will prioritize COVID-19-related inspections involving deaths or multiple hospitalizations due to occupational exposures to COVID-19. In addition, this NEP includes a focus on worker protection from retaliation. Where practical, OSHA will perform on-site workplace inspections. 26 Mar 2021: Enforcement begins Targeted Industries: Healthcare, meat processing, restaurants, correctional institutions Secondary Targeted Industries: Shipbuilding and Repair * NOTE: For certain industries such as these (Postal Services, NAICS 491110, Ship Building and Ship Repairing, NAICS 336611, and Construction, NAICS 236xxx, 237xxx, 238xxx), some of which have had a large number or high rate of COVID- 19-related complaints in some communities during 2020, Area Directors should use discretion based on local information pertaining to COVID-19-related workplace exposures, to determine whether an industry should be considered in the generating of their master lists of establishments. 10

MACOSH Membership The composition of MACOSH is as follows: Four members represent management; Four members represent labor; Three members represent the occupational safety and health professions; and Four members represent government, one of which must be from a state safety and health agency, and one must be designated by the Secretary of the Health and Human Services. Members serve two-year terms. At the discretion of the Secretary, members may be appointed to successive terms, or may be removed and replaced at any time. MACOSH Membership (2019 - 2021) Government Interests A new Committee with a new 2-year charter is currently being selected by OSHA Matthew Layman U.S. Coast Guard (USCG) James Rone Washington State Department of Labor and Industries Division of Occupational Safety and Health Alice Shumate National Institute for Occupational Safety and Health Regina Farr U.S. Department of Transportation Maritime Administration Worker Interests Robert Fiore International Longshoremen's Association Michael Podue International Longshore and Warehouse Union; Local 63 James Reid International Association of Machinists and Aerospace Workers Robert Godinez International Brotherhood of Boilermakers - Iron Shipbuilders Employer Interests David Turner VP SSE NYK Ports Donald V. Raffo Electric Boat Corporation William Crow Virginia Ship Repair Association Jeremy Riddle BalTerm, LLC - South Locust Point Marine Terminal Professional Organization Interests Amy Sly Liu Marine Chemist Association Gunther Hoock National Safety Council Lawrence Russell National Fire Protection Association Special Agency Liaison Julia Hearthway, Director, OWCP Department of Labor Special Agency Liaison (SAL) for MACOSH 11

MACOSH Maritime Advisory Committee on Occupational Safety and Health (MACOSH): Notice of Meeting MACOSH will meet from 1:00 p.m. to 4:00 p.m., ET, Tuesday, March 30, 2021. Dial-in number: 1-888-946-6302; Passcode: 5047691. 12

MACOSH Shipbuilding Sub-Group Working Committee Products Document Status Hydrogen Sulfide Document Under Development - Outline Heat Stress in Confined Spaces Document Under Development - Outline Shipyard Competent Person Document Ready for Full-Committee Vote Confined Space Hazards Ready for Full-Committee Vote Accountability for Safety in the Workplace Ready for Full-Committee Vote Hazards Associated with Preservative Coatings during Hot Work Complete Agency Recommendation Fire Watch Document Complete Agency Recommendation 13

EPAs new Stormwater Multi-Sector General Permit rule 15 Jan 2021 MSGP Final Rule Published in Federal Register 1 Mar 2021 Effective date 30 May Deadline to submit Notice of Intent (NOI) for new permit Facilities must consider implementing enhanced stormwater control measures such as structural improvements and enhanced/resilient pollution prevention measures to minimize impacts from stormwater discharges from major storm events such as hurricanes, storm surge, extreme/heavy precipitation, and flood events. Examples: elevate materials, temporarily reduce outdoor storage, delay deliveries. 14

2021 MSGP Changes Facilities must post a sign of permit coverage at a safe, publicly accessible location in close proximity to the facility, including facility contact information, how to obtain the SWPPP, and how to contact EPA (an exception is where other laws or local ordinances prohibit such signage). Facilities without sector-specific benchmarks conduct indicator monitoring for pH, TSS, and COD Certain facilities conduct indicator monitoring for polycyclic aromatic hydrocarbons (PAHs) includes sector R (Shipbuilding and Repair) Revised aluminum, copper (freshwater), selenium (freshwater), and cadmium benchmarks based on new final EPA WQ criteria. Removed iron and magnesium benchmark due to lack of documented toxicity. Allowing facilities to conduct site-specific risk analysis for aluminum and copper benchmark exceedances. 15

2021 MSGP Changes Schedule changes Benchmark monitoring required quarterly for first four quarters. If annual average is below benchmark threshold, facilities can discontinue until 4th year of coverage when quarterly monitoring is required again. Monitoring must continue if exceedance occurs (AIM is triggered). Additional Implementation Measures (AIM) for benchmark exceedances Level 1: While in baseline status, a triggering event (exceedance) occurs, then must review SWPPP/ control measures, implement additional measures (if necessary), and continue monitoring until no exceedance. Level 2: While in Level 1, a triggering event (exceedance) occurs, then must implement additional pollution prevention/good housekeeping measures and continue monitoring until no exceedance. Level 3: While in Level 2, a triggering event (exceedance) occurs, then must install permanent structural source and treatment controls and continue monitoring until no exceedance. 16

Future EH&S Plan and Suggested Topics EH&S Shipyard Contacts (WC, H&S, Env). Meeting discussion Topics Future research suggestions Fall Meeting TBD EH&S Metrics and Lessons Learned Round Table Worker Compensation Environmental Health & Safety Regulator Updates Panel Project Updates 17