Efficient Stock Room Setup for Inventory Management

Explore examples and guidelines for setting up a stock room efficiently to manage inventory effectively. Learn about designated areas, control systems, issue points, and basic office requirements to ensure smooth stock operations. The module focuses on providing flexible solutions adaptable to various educational agency settings, emphasizing accountability in inventory management.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

INVENTORY TRAINING MODULE 1 STOCK ROOM EVALUATION SETUP MINIMAL REQUIREMENTS Stock Room Layout BSIP application examples Stock room photo examples NCDPI Transportation Services September, 2014

MODULE OBJECTIVES MODULE OBJECTIVES Inventory management requires certain processes to be successful and can be accomplished multiple ways to fit your LEA s situation. Modules were created understanding LEA s operate differently with different types of staff however accountability is still required. The modules objective is to offer suggestions that can be shaped to any LEA when current staff share responsibilities. NCDPI Transportation Services September, 2014

Stock Room Setup Area designated for inventory storage that maintains control from receipt until issue. NCDPI Transportation Services September, 2014

Stock Room Setup This is another example of shelf setup to organize and manage inventory NCDPI Transportation Services September, 2014

Stock Room Control Stock Room Control Staff member or members designated to manage inventory need a certain amount of authority in order to control stock movement NCDPI Transportation Services September, 2014

Stock Issue Point Designate an area dedicated to order and issue inventory which controls access to the inventory. NCDPI Transportation Services September, 2014

Stock Issue Point This photo illustrates another example of an inventory issue point from inside the stockroom. NCDPI Transportation Services September, 2014

Basic inventory office requirements There are certain items needed in order to manage the order receipt and issuance of inventory. The above photo shows such an area. NCDPI Transportation Services September, 2014

Stock Room Layout Stock Room Layout Review and access the area designated as stock room to determine the layout to make flow of inventory more efficient and easily managed. NCDPI Transportation Services September, 2014

Stock Room Layout Stock Room Layout Design the area to create adequate space for bins, shelves or cabinets required to organize the inventory you manage. NCDPI Transportation Services September, 2014

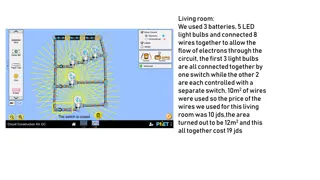

Remote Stock Room Setup Remote Stock Room Setup Setup or create mobile stock room locations in BSIP during this process in the event stock is maintained on service vehicles. This is a must to maintain inventory control. NCDPI Transportation Services September, 2014

Service Truck Stock Area Service Truck Stock Area Setup an area accessible to service truck staff to replenish truck inventories daily. These items pulled by stock room staff each business day to accomplish this process. NCDPI Transportation Services September, 2014

Specialty Storage Area Items requiring special storage such as chemicals should be considered to meet OSHA requirements during the area design such as the above photo NCDPI Transportation Services September, 2014

Stock Room Layout Create a map or legend of the stock room and any separate locations such as tire and grease rooms containing inventory to assist all personnel who might assist in the process in the event inventory is not their primary duty. This legend should also show exits in the event of an emergency. NCDPI Transportation Services September, 2014

Bin / Shelf Location Setup Bin / Shelf Location Setup Location setup in BSIP is recommended for multiple reasons To assist during daily issuance and restocking of inventory. To assist locating items by staff not familiar with the locations To assist in locating items during the annual inventory process NCDPI Transportation Services September, 2014

Shelf Setup Examples There are various ways to setup shelves and Bins as the picture above shows one example of good setup and labeling technics. NCDPI Transportation Services September, 2014

Drawer Storage Example The above example shows storage in cabinet with drawers that allows small parts storage by bin location. NCDPI Transportation Services September, 2014

Bin / Location Setup Process Process for setup of bin and shelf locations in stock room The creation of additional stock room locations such as service vehicles Remote locations such as tire, battery, oil and bulk storage areas Stock movement instructions is a BSIP process and contained on next slides. NCDPI Transportation Services September, 2014

Adding Storage Bin Descriptions - ZIE02D Storage Bin Description is a Text Sort: B-03 Sort: B-01 B-02 B-03 B-04 B-3 Sort: B-29 B-3 B-30 B-31 NCDPI Transportation Services September, 2014

Setting Up Service Trucks Setting Up Service Trucks Each LEA has a main storage location and some number of additional storage locations for their use The LEA decides what each number is used for each location It is not tracked in BSIP or linked to any particular inventory number of truck Look up storage locations: MB51 Transfer materials to storage locations: MIGO If more locations are needed email bsip.incidents@its.nc.gov NCDPI Transportation Services September, 2014

Looking up Available Storage Locations MB51 Enter plant and click Match Code Icon on Storage Location NCDPI Transportation Services September, 2014

Transfer Materials Between Storage Locations - MIGO Click to add another material NCDPI Transportation Services September, 2014

Module 1 Final Statement Module 1 Final Statement The previous slides have shown recommendations and technics that are necessary in order to maintain a stock room location. These examples are very basic and can be expanded upon in order to make them work at your LEA. Transportation Services hopes this first module has been helpful for new and existing staff in the effort to improve on accountability of inventory items. Modules on other topics to follow. NCDPI Transportation Services September, 2014

INVENTORY TRAINING MODULE 1 STOCK ROOM EVALUATION SETUP MINIMAL REQUIREMENTS Stock Room Layout BSIP application examples Stock room photo examples NCDPI Transportation Services September, 2014

undefined

undefined