Chemical Process Industries at University of Diyala

Glass is a versatile material with various applications in daily life. It is made from natural raw materials and fabricated through processes such as blowing, drawing, and pressing. Different types of glass like soda-lime and potash-lime offer distinct properties for specific uses. The art of glass fabrication involves shaping the hot, viscous material into various forms like laminated safes glass, foam glass, and structured glass. Explore the world of glass industries and learn about the unique characteristics of different glass types.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Chemical Process Industries University of Diyala Chemical Engineering Department Lecture (6) .

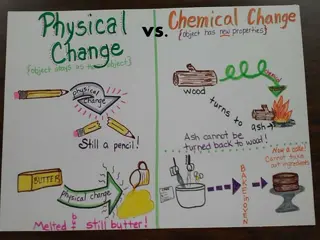

Glass industries Glass: Glass is a solid-like and transparent material that is used in numerous applications in our daily lives. Glass is made from natural and abundant raw materials (sand SiO2, soda ash Na2CO3 ,limestone CaCO3 and cullets ) that are melted at very high temperature to form a new material: glass. At high temperature glass is structurally similar to liquids, however at ambient temperature it behaves like solids. As a result, glass can be poured, blown, press and moulded into plenty of shapes.

Glass Fabrication: (Forming operation) The art of preparing glass materials articles from the hot and viscous glass fluid is termed as fabrication. Important processes are: 1. Blowing 2. Flat drawing and rolling 3. Pressed glass 4. Fiber glass

5. Laminated safes glass 6. Foam glass 7. Structured glass or glass brick or building block 8. Glass Crete block , like wood work

Types of glass: 1) Soda-lime glass or soft glass: most common form of glass produced. It is composed of about 70% silica (silicon dioxide), 15%soda (sodium oxide), and 9% lime (calcium oxide), with much smaller amounts of various other compounds. The soda serves as a flux to lower the temperature at which the silica melts, and the lime acts as a stabilizer for the silica. Soda-lime glass is inexpensive, chemically stable, reasonably hard, and extremely workable, because it is capable of being resoftened a number of times if necessary to finish an article.

2) Potash lime or hard glass: Silica (sand), calcium carbonate and potassium carbonate are the basic raw material for potash lime glass. Their approximate composition is K2O.CaO.6SiO2. They possess high melting point, fuse with difficulty and have good resistance to acids, alkalis and other solvents compare to ordinary glasses. These glasses are costlier than soda-lime glasses and are used for chemical apparatus, combustion tubes, etc., which are to be used for heating operations.

Alumino-silicate glass: a typical analysis 55%SiO2 23% Al2O3 7%B2O3 9% MgO 5%CaO 1%Na2O & K2O This type high softening temperature are used d for high pressure mercury discharge tubes chemical combustion tube, certain domestic equipment etc.