Caterpillar Cat 140M 3 MOTOR GRADER (Prefix N9M) Service Repair Manual Instant Download

Please open the website below to get the complete manualnn//

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Service Repair Manual Models 140M3 M OTOR GRADER

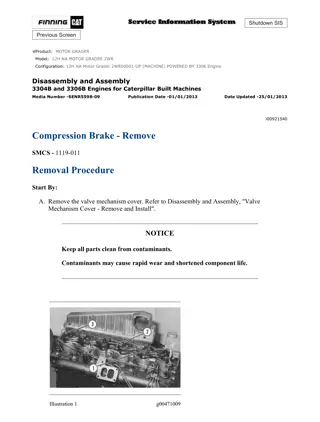

140M Series 3 Motor Grader N9M00001-UP (MACHINE) POWERED BY C9.3 Engi... 1/5 Shutdown SIS Previous Screen Product: MOTOR GRADER Model: 140M 3 MOTOR GRADER N9M Configuration: 140M Series 3 Motor Grader N9M00001-UP (MACHINE) POWERED BY C9.3 Engine Disassembly and Assembly 12M Series 3, 140M Series 3 and 160M Series 3 Motor Graders Machine Systems Media Number -UENR3488-02 Publication Date -01/09/2018 Date Updated -24/09/2018 i02872843 Bank Valve - Remove - Front Frame SMCS - 5051-011 Removal Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 311-1362 Vacuum Cap 1 B 138-7573 Link Bracket 2 NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. NOTICE Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting, and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2020/1/1

140M Series 3 Motor Grader N9M00001-UP (MACHINE) POWERED BY C9.3 Engi... 2/5 Refer to Special Publication, PERJ1017, "Dealer Service Tool Catalog" for tools and supplies suitable to collect and contain fluids on Cat products. Dispose of all fluids according to local regulations and mandates. Note: Put identification marks on all lines, on all hoses, on all wires, and on all tubes for installation purposes. Plug all lines, hoses, and tubes. This helps to prevent fluid loss and this helps to keep contaminants from entering the system. 1. Lower the blade to the ground. 2. Release the system pressure. Refer to Operation and Maintenance Manual, "System Pressure - Release". Illustration 1 g01368952 3. Install Tooling (A) onto the hydraulic tank. Attach an air supply hose onto Tooling (A). Apply 138 kPa (20 psi). This procedure will pull a vacuum on the hydraulic system. Illustration 2 g01430785 4. Loosen bolts (1). Remove bolts (2). Use two people in order to remove cover (3). The weight of cover (3) is approximately 32 kg (70 lb). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2020/1/1

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

140M Series 3 Motor Grader N9M00001-UP (MACHINE) POWERED BY C9.3 Engi... 3/5 Illustration 3 g01430795 5. Disconnect tube assemblies (4) and tube assemblies (5). 6. Disconnect harness assembly (6). Repeat this step for the opposite side. 7. Disconnect hose assemblies (7) and hose assemblies (8). Illustration 4 g01430802 8. Disconnect tube assemblies (9). Disconnect tube assembly (10). Disconnect tube assembly (11). Illustration 5 g01430845 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2020/1/1

140M Series 3 Motor Grader N9M00001-UP (MACHINE) POWERED BY C9.3 Engi... 4/5 9. Disconnect tube assembly (12). Illustration 6 g01430852 10. Attach Tooling (B) and a suitable lifting device onto bank valve (13). The weight of bank valve (13) is approximately 73 kg (160 lb). Illustration 7 g01430857 Illustration 8 g01430860 11. Remove bolt (14), bolts (15), and bolts (16). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2020/1/1

140M Series 3 Motor Grader N9M00001-UP (MACHINE) POWERED BY C9.3 Engi... 5/5 Illustration 9 g01430859 12. Remove bank valve (13). Copyright 1993 - 2020 Caterpillar Inc. Wed Jan 1 15:37:44 UTC+0800 2020 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2020/1/1

140M Series 3 Motor Grader N9M00001-UP (MACHINE) POWERED BY C9.3 Engi... 1/8 Shutdown SIS Previous Screen Product: MOTOR GRADER Model: 140M 3 MOTOR GRADER N9M Configuration: 140M Series 3 Motor Grader N9M00001-UP (MACHINE) POWERED BY C9.3 Engine Disassembly and Assembly 12M Series 3, 140M Series 3 and 160M Series 3 Motor Graders Machine Systems Media Number -UENR3488-02 Publication Date -01/09/2018 Date Updated -24/09/2018 i02712425 Bank Valve - Disassemble - Front Frame SMCS - 5051-015 Disassembly Procedure Start By: a. Remove the bank valves. Refer to Disassembly and Assembly, "Bank Valve - Remove". NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. Note: Inspect the O-ring seals. Replace the O-ring seals that are worn or damaged. Illustration 1 g01362617 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2020/1/1

140M Series 3 Motor Grader N9M00001-UP (MACHINE) POWERED BY C9.3 Engi... 2/8 1. Remove nuts (1). Illustration 2 g01362643 2. Remove cover (2). Remove seal (3). 3. Remove control valve (4). Remove seal (5). Repeat this step for the remaining control valves. Illustration 3 g01362654 4. Remove plug (6). Illustration 4 g01362657 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2020/1/1

140M Series 3 Motor Grader N9M00001-UP (MACHINE) POWERED BY C9.3 Engi... 3/8 Personal injury can result from being struck by parts propelled by a released spring force. Make sure to wear all necessary protective equipment. Follow the recommended procedure and use all recommended tooling to release the spring force. 5. Remove plug (7). Remove check valve (8). Remove bolt (9) in order to remove solenoid (10). Remove check valve (11). Remove bolt (12) in order to remove solenoid (13). Remove plug (14). Illustration 5 g01362672 Personal injury can result from being struck by parts propelled by a released spring force. Make sure to wear all necessary protective equipment. Follow the recommended procedure and use all recommended tooling to release the spring force. 6. Remove plug (15). Remove spring (16). Remove ball (17). Remove spring (18). Remove spool (19). Remove plug (20). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2020/1/1

140M Series 3 Motor Grader N9M00001-UP (MACHINE) POWERED BY C9.3 Engi... 4/8 Illustration 6 g01362677 7. Remove pistons (21). Illustration 7 g01362680 Personal injury can result from being struck by parts propelled by a released spring force. Make sure to wear all necessary protective equipment. Follow the recommended procedure and use all recommended tooling to release the spring force. 8. Remove bolts (22). Remove cover (23). Remove retainer (24). Remove spring (25). Remove retainer (26). Remove plug (27). Remove spool (28). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2020/1/1

140M Series 3 Motor Grader N9M00001-UP (MACHINE) POWERED BY C9.3 Engi... 5/8 Illustration 8 g01362689 Personal injury can result from being struck by parts propelled by a released spring force. Make sure to wear all necessary protective equipment. Follow the recommended procedure and use all recommended tooling to release the spring force. 9. Remove bolts (29). Remove cover (30). Remove retainer (31). Remove spring (32). Remove retainer (33). Remove plug (34). Illustration 9 g01362691 10. Remove O-ring seals (35) and backup ring (36) from check valve (8). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2020/1/1

140M Series 3 Motor Grader N9M00001-UP (MACHINE) POWERED BY C9.3 Engi... 6/8 Illustration 10 g01362713 11. Remove O-ring seals (37) and backup ring (38) from check valve (11). Illustration 11 g01362720 12. Remove O-ring seals (39) from solenoid (10). Illustration 12 g01362723 13. Remove O-ring seals (40) from solenoid (13). 14. Repeat Step 5 through Step 13 for the remaining control valves. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2020/1/1

140M Series 3 Motor Grader N9M00001-UP (MACHINE) POWERED BY C9.3 Engi... 7/8 Illustration 13 g01362729 15. Remove tie rods (41). Illustration 14 g01362732 16. Remove fittings (42). Remove fitting (43). Remove fitting (44). Remove plugs (45). Illustration 15 g01362737 17. Remove orifice (46). Copyright 1993 - 2020 Caterpillar Inc. Wed Jan 1 15:38:40 UTC+0800 2020 All Rights Reserved. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2020/1/1

140M Series 3 Motor Grader N9M00001-UP (MACHINE) POWERED BY C9.3 Engi... 1/8 Shutdown SIS Previous Screen Product: MOTOR GRADER Model: 140M 3 MOTOR GRADER N9M Configuration: 140M Series 3 Motor Grader N9M00001-UP (MACHINE) POWERED BY C9.3 Engine Disassembly and Assembly 12M Series 3, 140M Series 3 and 160M Series 3 Motor Graders Machine Systems Media Number -UENR3488-02 Publication Date -01/09/2018 Date Updated -24/09/2018 i05440670 Bank Valve - Disassemble - Rear Frame SMCS - 5051-015 Disassembly Procedure Start By: a. Remove the bank valves. Refer to Disassembly and Assembly, "Bank Valve - Remove". NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. Illustration 1 g03434195 1. Remove nuts (1). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2020/1/1

140M Series 3 Motor Grader N9M00001-UP (MACHINE) POWERED BY C9.3 Engi... 2/8 Illustration 2 g03434219 2. Remove cover (2). Remove seal (3). 3. Remove control valve (4). Remove seal (5). Repeat this step for the remaining control valves. Illustration 3 g03434232 Personal injury can result from being struck by parts propelled by a released spring force. Make sure to wear all necessary protective equipment. Follow the recommended procedure and use all recommended tooling to release the spring force. 4. Remove plug (6). Remove check valve (7). Remove bolt (8) in order to remove solenoid (10). Remove check valve (9). Remove bolt (11) in order to remove solenoid (12). Remove plug (13). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2020/1/1

140M Series 3 Motor Grader N9M00001-UP (MACHINE) POWERED BY C9.3 Engi... 3/8 Illustration 4 g01361634 Personal injury can result from being struck by parts propelled by a released spring force. Make sure to wear all necessary protective equipment. Follow the recommended procedure and use all recommended tooling to release the spring force. 5. Remove plug (14). Remove spring (15). Remove ball (16). Remove spring (17). Remove spool (18). Remove plug (19). Illustration 5 g01361643 6. Remove pistons (20). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2020/1/1

140M Series 3 Motor Grader N9M00001-UP (MACHINE) POWERED BY C9.3 Engi... 4/8 Illustration 6 g01361658 Personal injury can result from being struck by parts propelled by a released spring force. Make sure to wear all necessary protective equipment. Follow the recommended procedure and use all recommended tooling to release the spring force. 7. Remove bolts (21). Remove cover (22). Remove retainer (23). Remove spring (24). Remove retainer (25). Remove plug (26). Remove spool (27). Illustration 7 g03434961 Personal injury can result from being struck by parts propelled by a released spring force. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2020/1/1

140M Series 3 Motor Grader N9M00001-UP (MACHINE) POWERED BY C9.3 Engi... 5/8 Make sure to wear all necessary protective equipment. Follow the recommended procedure and use all recommended tooling to release the spring force. 8. Remove bolts (28). Remove cover (29). Illustration 8 g03435437 9. Remove O-ring seals (30) from check valve (7). Illustration 9 g03435456 10. Remove O-ring seals (31) from check valve (10). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2020/1/1

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

140M Series 3 Motor Grader N9M00001-UP (MACHINE) POWERED BY C9.3 Engi... 6/8 Illustration 10 g03435645 11. Remove O-ring seals (32) from solenoid (9). Illustration 11 g03435658 12. Remove O-ring seals (33) from solenoid (12). 13. Repeat Step 3 through Step 12 for the remaining control valves. Illustration 12 g03435661 14. Remove tie rods (34). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2020/1/1

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com