Caterpillar Cat 120G MOTOR GRADER (Prefix 87V) Service Repair Manual Instant Download 11

Please open the website below to get the complete manualnn//

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Service Repair Manual Models 120G M OTOR GRADER

120G MOTOR GRADER 87V01138-05274 (MACHINE) POWERED BY 3304 ENG... 2/10 Start By: a. remove axles 1. Remove the nut that holds the sprockets on the shaft with tooling (A). Install tooling (B) on the shaft. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/17

120G MOTOR GRADER 87V01138-05274 (MACHINE) POWERED BY 3304 ENG... 3/10 2. Lift the machine off the ground. Install tooling (D) under the rear frame as shown. Remove the bolts that hold covers (1) from the tandem housing. Remove covers (1). 3. Install tooling (C) on the rear wheels. Fasten a hoist to the tandem housing and tooling (C). Install tooling (E) between tooling (C) and the hoist to help keep the tandem housing in balance. Disconnect the air line from the tandem housing. 4. Remove nuts (2) and the washers that hold the tandem housing to the final drive housing. 5. Move the tandem housing away from the final drive housing and on to tooling (B). NOTE: Tooling (B) keeps the sprockets in their correct positions in the tandem housing. 6. Remove tooling (B) from the shaft. Do not remove tooling (B) from the sprockets. 7. Move the tandem housing away from the machine. Weight is 1043 kg (2300 lb.). 8. Remove O-ring seal (3) from the housing. Remove bearing (4) from the shaft. 9. Remove bolts (5) that hold retainer (6) to the housing. Remove retainer (6). 10. Remove the washer that is between the final drive housing and retainer (6). The washer is in three sections. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/17

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

120G MOTOR GRADER 87V01138-05274 (MACHINE) POWERED BY 3304 ENG... 4/10 11. Install two 5/8" - 11 NC forged eyebolts (11) and nuts in the housing as shown. Put a fork lift truck in position under the housing. Install tooling (F) on the lift truck and the eyebolts. 12. Pull the outer housing (8) from the inner housing with tooling (F). 13. Remove two oscillation bearing rings (9) from the housings. Remove washer (7) from the inner housing. Washer (7) is in three sections. 14. Put tooling (G) and a floor jack in position under inner housing (13). A rag can be put between tooling (G) and the housing to prevent damage to the housing. 15. Remove nuts (10) and the washers that hold inner housing (13) to the bevel gear case. 16. Install two 3/4" - 10 NC forcing screws (14) in the housing. Remove the inner housing far enough to install tooling (H) on the housing. Fasten a hoist to tooling (H). Put an axle in position in the final drive housing to help keep the housing in balance. 17. Install a wire around the forcing screws and the planet carrier to keep the planet carrier from falling. Remove inner housing (13) and the planet carrier. Weight is 163 kg (360 lb.). Remove O- ring seal (12). Remove the O-ring seal from the inside surface of inner housing (13). 18. Put the final drive housing in position on blocks with the planet carrier up. Remove the wire and the forcing screws from the housing. 19. Remove pinion (16) from planet carrier (15). Fasten a hoist to planet carrier (15) and remove it. Weight is 41 kg (90 lb.). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/17

120G MOTOR GRADER 87V01138-05274 (MACHINE) POWERED BY 3304 ENG... 5/10 20. Bend the locks away from the bolts that hold shafts (17) to the planet carrier. Remove the locks and the bolts. Remove retainers (18) from the shafts. 21. Remove shafts (17) from the planet carrier. Remove gears (21) and washers (20) from the planet carrier. Remove rollers (19) from gears (21). 22. Remove ring (23) from the planet carrier with tooling (I). Remove washer (22) from the planet carrier. 23. Bend the locks away from bolts (25). Remove bolts (25). Remove plates (26) that hold ring (24) to the housing. 24. Remove ring gear (24). Weight is 17 kg (38 lb.). 25. Remove shaft (27) from the housing. Weight is 18 kg (40 lb.). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/17

120G MOTOR GRADER 87V01138-05274 (MACHINE) POWERED BY 3304 ENG... 6/10 26. Remove bearing (28) from shaft (27) with tooling (J). 27. Remove bearing cup (29) from the housing with tooling (K). Remove the lip-type seal from the housing. Remove the bearing cup from the other end of the housing with a hammer and a punch. 28. Do Steps 1 through 27 for the other final drive. Assemble Final Drives https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/17

120G MOTOR GRADER 87V01138-05274 (MACHINE) POWERED BY 3304 ENG... 7/10 1. Lower the temperature of bearing cup (29). Install bearing cup (29) in the housing. 2. Install the seal in the housing with tooling (J). Install the seal with the lip toward bearing cup (29). Put clean oil on the seal. 3. Put inner housing (13) in position on blocks as shown. Lower the temperature of the bearing cup and install it in the housing. 4. Heat bearing (28) in oil to a maximum temperature of 135 C (275 F). Install bearing (28) on shaft (27). Install the shaft and the bearing in the bearing cup and housing (13). 5. Put ring gear (24) in position on housing (13). Install plates (26) in the groove of the ring gear. Install the locks and bolts (25) on the plates. Bend the locks against the bolts. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/17

120G MOTOR GRADER 87V01138-05274 (MACHINE) POWERED BY 3304 ENG... 8/10 6. Install the washer in the carrier. Install the large retaining ring that holds the washer with tool (B). 7. Install the rollers in the gears. Install the gears and the washers in planet carrier (30). Install shafts (17) that hold the gears in the planet carrier. Install the retainers, the bolts and the locks that hold the retainers. Bend the lock against the bolts. 8. Put the carrier on its other end. Fasten a hoist to the carrier. Put planet carrier (30) in position on shaft (27) and in ring gear (24). Install pinion (16) in the planet carrier. Install a wire to hold the planet carrier in position in the housing. 9. Install O-ring seal (31) on the housing. Install tooling (C) on housing (4). Fasten a hoist to tooling (C). Lift housing (4) and put it in position on tooling (D) and a floor jack. Put axle in position in the housing to help keep the housing in balance. 10. Move the final drive housing toward the bevel gear case. Remove the wire that holds the planet carrier in the housing. Remove tooling (C) and the hoist from the housing. 11. Put the final drive housing in position over the studs in the bevel gear case. Install the nuts and the washers that hold it. Remove tooling (D). 12. Tighten nuts (10) to a torque of 440 20 N m (320 15 lb.ft.). Install O-ring seal (33) on the housing. Put STP OIL TREATMENT or CASITE MOTOR HONEY on the seal. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/17

120G MOTOR GRADER 87V01138-05274 (MACHINE) POWERED BY 3304 ENG... 9/10 13. Install tooling (E) on the outer housing. Fasten a hoist to tooling (E). Put some oil on the inside surfaces of the oscillation bearing rings (9) and on the outside surface of the inner housing. Install rings (9) in outer housing (8). Install washer (7) on the inner housing. Washer (7) is in three sections. Put some clean grease on the washer. 14. Put housing (8) in position on the inner housing. Rings (9) and housing (8) can be moved with a soft hammer if necessary. Remove tooling (E). 15. Install bearing (4) on the shaft. Install washer (34) on the face of the outer housing. Washer (34) is in three sections. Put some clean grease on the washer. Install retainer (6) on the washer. Install the bolts and the washers that hold the retainer. Tighten the bolts to a torque of 250 15 N m (185 11 lb.ft.). 16. Install tooling (H) on the rear wheels. Fasten a hoist and chains to the tandem housing. Fasten chains and tooling (F) to the hoist and the rear wheels. Put the tandem housing and tooling (G) in position on the final drive housing and the shaft. Install the nuts and the washers that hold the tandem housing to the final drive housing. Tighten the nuts to a torque of 250 15 N m (185 11 lb.ft.). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/17

120G MOTOR GRADER 87V01138-05274 (MACHINE) POWERED BY 3304 EN... 10/10 17. Remove tooling (F) and (H) from the tandem housing and the rear wheels. Remove tooling (G) from the sprockets. Connect air line (35) to its correct location. Install the covers and the gaskets on the tandem housing. Install the nut that holds the sprockets on the shaft. NOTICE The following procedure must be used to put the correct amount of preload on the bearings for the final drive: a. Tighten the nut to a torque of 135 N m (100 lb.ft.) with tooling (A). b. Turn the wheels to put the bearings in their seats. c. Hit the hub of the sprocket with a large punch and a hammer. d. Repeat Steps a, b and c until the nut does not turn when it is tightened. e. Loosen the nut. f. Tighten the nut to a torque of 70 N m (50 lb.ft.). g. If the nut is in a locking position, install the axle, the cover and bolts. h. If the nut is not in a locking position, tighten the nut to the next nearest locking position. Install the axle, the cover and the bolts. 18. Bend the locks against the bolts. Fill the tandem housing with oil to its correct level. 19. Do Steps 1 through 18 for the other final drive. Copyright 1993 - 2020 Caterpillar Inc. Fri Apr 17 11:31:05 UTC+0800 2020 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/17

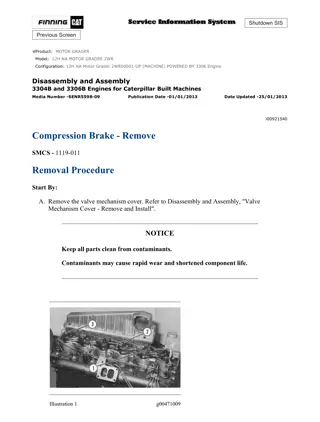

120G MOTOR GRADER 87V01138-05274 (MACHINE) POWERED BY 3304 ENG... 1/3 Shutdown SIS Previous Screen Product: MOTOR GRADER Model: 120G MOTOR GRADER 87V Configuration: 120G MOTOR GRADER 87V01138-05274 (MACHINE) POWERED BY 3304 ENGINE Disassembly and Assembly 12G, 120G, 130G & 140G MOTOR GRADERS POWER TRAIN Media Number -SENR3649-00 Publication Date -01/10/1987 Date Updated -27/09/2012 SENR36490008 Transmission Oil Filter Base SMCS - 3164-016; 3164-010; 3164-015 Remove And Install Transmission Oil Filter Base 1. Remove the plug at the bottom of oil filter (3) and drain the oil from the filter. Replace the plug. Remove the filter from the filter base. 2. Remove bolts (1) that hold the base to the transmission. Remove transmission oil filter base (2). NOTE: The following steps are for the installation of the transmission oil filter base. 3. Put transmission oil filter base (2) in position on the transmission. Install bolts (1) that hold the base to the transmission. 4. Install oil filter (3) on the oil filter base. Disassemble Transmission Oil Filter Base Start By: a. remove transmission oil filter base https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/17

120G MOTOR GRADER 87V01138-05274 (MACHINE) POWERED BY 3304 ENG... 2/3 1. Remove large O-ring seal (1) from the inside of the filter base. 2. Remove small O-ring seals (2) and (3) from the filter base. 3. Remove plug (6). Remove the O-ring seal from the plug. 4. Remove valve (5). Remove spring (4). Assemble Transmission Oil Filter Base https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/17

120G MOTOR GRADER 87V01138-05274 (MACHINE) POWERED BY 3304 ENG... 3/3 1. Install spring (4) in the oil filter base. 2. Put valve (5) in position in the base and over the spring. 3. Install the O-ring seal on plug (6). Install the plug in the base. 4. Install O-ring seal (1) in the oil filter base. 5. Install the two small O-ring seals in the ports for inlet and outlet oil for the base. End By: a. install transmission oil filter base Copyright 1993 - 2020 Caterpillar Inc. Fri Apr 17 11:32:01 UTC+0800 2020 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/17

120G MOTOR GRADER 87V01138-05274 (MACHINE) POWERED BY 3304 ENG... 1/6 Shutdown SIS Previous Screen Product: MOTOR GRADER Model: 120G MOTOR GRADER 87V Configuration: 120G MOTOR GRADER 87V01138-05274 (MACHINE) POWERED BY 3304 ENGINE Disassembly and Assembly 12G, 120G, 130G & 140G MOTOR GRADERS POWER TRAIN Media Number -SENR3649-00 Publication Date -01/10/1987 Date Updated -27/09/2012 SENR36490009 Relief Control Valve SMCS - 3182-010; 3182-015; 3182-016 Remove And Install Relief Control Valve 1. Put identification on oil lines (1) as to their location on the relief control valve. Remove oil lines (1) from the valve. 2. Remove bolts (2) that hold the valve to the transmission. Remove relief control valve (3). NOTE: The following steps are for the installation of the relief control valve. 3. Put relief control valve (3) in position on the transmission. Install bolts (2) that hold the valve to the transmission. 4. Connect oil lines (1) to their respective locations on the relief control valve. Disassemble Relief Control Valve Start By: https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/17

120G MOTOR GRADER 87V01138-05274 (MACHINE) POWERED BY 3304 ENG... 2/6 a. remove relief control valve 1. Remove the O-ring seals from the valve. 2. Remove bolts (1) that hold the five covers. Remove five covers (2). 3. Remove O-ring seal (6) and three springs (5) from the valve body. 4. Remove O-ring seal (3) and valve spool (4) from the body. 5. Remove spacers (9) from valve spool (4). 6. Remove spiral snap ring (7). Remove retainer (10), spring (8), and poppet (11) from the valve spool. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/17

120G MOTOR GRADER 87V01138-05274 (MACHINE) POWERED BY 3304 ENG... 3/6 7. Remove two plugs (12). Remove the O-ring seal from the plugs. Remove two pins (13) from the valve body. 8. Remove two O-ring seals (15) and two valves (14). 9. Put tool (A) into position in the collar of the valve. 10. Install the valve in a vise. Put the spring in compression approximately 6.4 mm (.25 in.). Remove pin (16) with a hammer and punch. 11. Slowly release the pressure on the spring and remove the valve from the vise. Remove tool (A). 12. Remove pin (21), retainer (20), spring (19) and valve (18) from collar (17). 13. Do Steps 9 through 12 for the other valve removed in Step 8. Assemble Relief Control Valve https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/17

120G MOTOR GRADER 87V01138-05274 (MACHINE) POWERED BY 3304 ENG... 4/6 1. Put poppet (11), spring (8), and retainer (10) in position in the valve spool. Install spiral snap ring (7) in the valve spool. 2. Put pin (21) in position in retainer (20). Put spring (19) and valve (18) in position on the retainer and pin. Put the side of collar (17) with a chamfer in position on the valve. 3. Install tool (A) in the collar. Install the valve in a vise. Put the hole in pin (21) in alignment with the small holes in the collar. Install the pin that holds the valve together. Remove the valve from the vise. 4. Do Steps 2 and 3 for the other valve. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/17

120G MOTOR GRADER 87V01138-05274 (MACHINE) POWERED BY 3304 ENG... 5/6 5. Put spacers (9) in position in valve (4). Put three springs (5) in position in the valve. 6. Put the springs and the valve in position in the valve body. 7. Put valves (14) in position in the valve body. 8. Install two pins (13) in the valve body. NOTE: Turn valves (14) to put the hole in the collar in alignment with pins (13). 9. Install the O-ring seal on the plugs. Install two plugs (12) in the valve body. 10. Install O-rings (3) in the valve body. Put five covers (2) in position on the valve body. Install bolts (1) that hold the covers. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/17

120G MOTOR GRADER 87V01138-05274 (MACHINE) POWERED BY 3304 ENG... 6/6 11. Install the O-ring seals on the back side of the valve body. Copyright 1993 - 2020 Caterpillar Inc. Fri Apr 17 11:32:57 UTC+0800 2020 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/17

120G MOTOR GRADER 87V01138-05274 (MACHINE) POWERED BY 3304 ENG... 1/7 Shutdown SIS Previous Screen Product: MOTOR GRADER Model: 120G MOTOR GRADER 87V Configuration: 120G MOTOR GRADER 87V01138-05274 (MACHINE) POWERED BY 3304 ENGINE Disassembly and Assembly 12G, 120G, 130G & 140G MOTOR GRADERS POWER TRAIN Media Number -SENR3649-00 Publication Date -01/10/1987 Date Updated -27/09/2012 SENR36490010 Transmission Oil And Scavenge Pump SMCS - 3153-010; 3153-015; 3153-016 Remove And Install Transmission Oil And Scavenge Pump 1. Loosen bolts (1), (2) and (6) and slide the alternator to loosen fan belts (3). 2. Remove fan belts (3) from the pulley on the transmission oil and scavenge pump. 3. Remove bolts (4) and plate (5). 4. Remove bolts (7) and washers. Remove pulley (8) and the O-ring seal. 5. Remove bolts (9) and remove tubes (11) from the pump. 6. Use two people and remove bolts (10), then lower transmission oil and scavenge pump (12) from the vehicle. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/17

120G MOTOR GRADER 87V01138-05274 (MACHINE) POWERED BY 3304 ENG... 2/7 NOTE: The following steps are for the installation of the transmission and scavenge pump. 7. Put transmission oil and scavenge pump (12) in position with bolts (10). 8. Install tubes (11) on the pump with bolts (9). 9. Install pulley (8) with bolts (7). 10. Install plate (5) with bolts (4) that hold it. 11. Install fan belts (3) on the pulley. 12. Slide the alternator into it's original position and tighten bolts (1), (2) and (6). Disassemble Transmission Oil And Scavenge Pump Start By: a. remove transmission oil and scavenge pump 1. Thoroughly clean the outside of the pump. 2. Remove bolts (3). Remove pulley (2) from pump (1). Remove the gasket from the pump. NOTE: Pulley (2) can be removed during the removal of the transmission oil and scavenge pump. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/17

120G MOTOR GRADER 87V01138-05274 (MACHINE) POWERED BY 3304 ENG... 3/7 3. Remove bolts (5). Remove cage (4) from the manifold. 4. Remove spiral snap ring (8) that holds coupling (6) in the cage. 5. Remove coupling (6) from the cage with tooling (A). 6. Remove seal (7) and the bearing from the cage. 7. Remove bolts (9) that hold cover (10) for the transmission oil pump section to the manifold for the scavenge pump section. 8. Remove cover (10). Remove the seal from the inside face of cover (10). 9. Remove the bearings from the cover with tooling (B). 10. Remove body (11) from over the gears for the transmission oil pump section. 11. Remove gear (12). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/17

120G MOTOR GRADER 87V01138-05274 (MACHINE) POWERED BY 3304 ENG... 4/7 12. Remove manifold (15) and gear (13) from manifold (18). Remove the key and gear (13) from the manifold. 13. Remove two seals (14) from manifold (15). Remove the bearings from the manifold with tooling (B). 14. Remove gears (16) and (17) for the scavenge pump section from manifold (18). Assemble Transmission Oil And Scavenge Pump https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/17

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

120G MOTOR GRADER 87V01138-05274 (MACHINE) POWERED BY 3304 ENG... 5/7 1. Install the two bearings in the manifold and the two bearings in the cover with tooling (A). 2. Install the bearings so the joint in the bearing is at an angle 30 15 to a vertical line through the centers of the bores for the gears. 3. Install the bearings to a depth of 1.57 mm (.062 in.) from the face of the manifold and the cover. 4. Put gears (16) and (17) for the scavenge pump section in position in manifold (18). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/17

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com