Benefits of UCD Sequencer in Power Management Solutions

UCD Sequencer offers full flexibility without coding, improved power reliability, fault logging, easy monitoring, and the addition of digital power features. It enhances system reliability, reduces inventory costs, and improves the quality of end products in server monitoring and sequencing solutions. With PMBus power sequencers, voltage, current, and temperature monitoring for up to 24 power rails can be achieved with accurate margining for improved energy efficiency and system reliability.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Benefits of UCD Sequencer over CPLD MCS TI Information Selective Disclosure TI Information Selective Disclosure

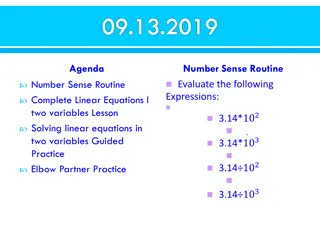

TI Sequencers Advantages Full Flexibility without Coding Power Engineers can use the free GUI tool to adjust timing, dependencies, debugging and display power sequences without the need to wait on software engineers or CPLD vendors. No coding or board changes are needed. NV Fault Logs for Easy Debugging Complete fault logs with time stamps are saved in NVM for extremely easy debugging E-Scope for Easy Monitoring High speed sampling on the voltage and current signals enables easy transient monitoring on board without attaching scope probes Improved Power Reliability Up to 24 rail Close Loop Margining can improve product reliability and reduce inventory for lower operation cost and higher quality end products Offer Most Benefits of Digital Power Add telemetry, power metering and other features to all power rails without the cost of redesigning the power tree. PMBus enabled POL controller choices on the market are still limited. TI Information Selective Disclosure 2

Server Monitoring and Sequencing Solutions Traditional Configuration Newer Alternative Configuration Monitoring BMC BMC Full Power Monitoring, Sequencing, and logging PMBus/I2C GPIO UCD90xxx Power Sequencers Sequencing CPLD Over the past 5+ years, TI helped large server customers to adopt integrated power monitoring and GPIO solution, which is powerful, flexible, easy to debug and improves system reliabilities. 3

PMBus Power Sequencers and Manager Voltage, Current, Temperature Monitoring for up to 24 Power Rails Reporting on PMBus/I2C Flexible with GUI support, no coding needed Up to 84 GPIO (expendable) with Boolean Logic Builder Fan Temperature Control with Speed Detection Cascading to up to 96 Rails Synchronized Outputs and Time Base Watchdog & System Reset System Clock Highest density on the market 4

Accurate Margining for Improved Reliability and Energy Saving Closed Loop Margining provides a convenient way of accurately adjust output voltage on virtually ANY POL power rails Triggered by GPI input or PMBus/I2C commands System level test with voltage margining is becoming a standard way to improve system reliability Highly accurate active trimming (margining continuously) can be used to fine tune output voltages (remove voltage set point errors), or dynamically adjust output voltages for energy savings. 5

Advanced Metering Integrated V, I and T monitoring and telemetry enables full power monitoring and metering on all power rails. Standard PMBus command are supported to read power and other parameters Power Meter feature is offered with many advanced server management software such as HP iLO (as a paid optional module) Power savings can be obvious from the chart 6

Advanced Logging Debugging is very efficient with key fault and operation information stored in Non-Volatile memory. Logs can be retrieved via PMBus/I2C remotely. All logging is done independently with single power supply, ideal for debugging power failures Peak values are saved to detect system stress over long period of time Fault type, values and time stamp shows clear evidence of system failures On first fault, all GPIO and rail information is saved together with the fault information for detailed debugging 7

E-Scope The latest UCD90320 has a advanced HW platform enables advanced E-Scope Able to store waveforms of transient Display the waveforms on computer screen with Fusion App GUI with 8x memory than the previous gen ADC sampling is at 1MPS For the assigned rail, perform fast ADC sampling at 10us rate Circular buffer to store the ADC result for the GUI polling. 8

Use Cases 1 Online Debugging Customer has free Fusion GUI tool running on a PC, which is connected to a UCD90xxx sequencer. It is much more convenient than using a scope to probe all power rails. Adjustments on timing, dependencies, and debugging sequence (e.g. enables partial rails) can be done easily on the fly without coding Shows margin operation after losing power 9

Use Cases 2 Field Failure Analysis One major server customer has field failure reported. Some of the servers reported can t boot up The project files were retrieved remotely, which contains fault logs. Use Fusion GUI to open the project file, it is obvious that Rail #7 has an UV fault after Pgood has been reached. Other rails were shut down automatically, but not the source of the failure. 10

Summary of Benefits CPLD UCD90xx Monitoring Very limited (Pgood) V, I, T monitoring and telemetry, power meters, fault response, easy online monitoring (no O-scope needed) Peak, Fault, and Black Box logging in NVM, easy remote failure analysis Independent logging, single 3.3V power supply needed Closed loop high accuracy margining, can be used to calibrate rail voltages or use as adjustable voltage rails to reduce power consumption Debugging Limited or no fault logging Rely on BMC Margin Open loop, inaccurate, need external FET 11