Pump Efficiency and Power Calculation Examples

This content provides detailed calculations for pump efficiency and power requirements in fluid power systems. It covers scenarios involving pump displacement, input torque, electric motor efficiency, volumetric and mechanical efficiencies, and power delivered to loads. The solutions include formulas and step-by-step calculations for determining overall efficiency, theoretical torque, input power, and torque required to drive the pump.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

1 Example 2.13 3 3 A pump has a displacement volume of 120 cm . It delivers 0.0015 m /s at 1440 RPM and 60 bar. If the prime mover input torque is 130 Nm. What is the overall efficiency of the pump? What is the theoretical torque required to operate the pump. The pump is driven by an electric motor having an overall efficiency of 88%. Solution: Given volumetric displacement, , input torque = 120 /s, , , . Total number of working hours available 3 Volumetric displacement in m /rev is = Theoretical dischargecan be calculated as Now we can calculate the volumetric efficiency as Mechanical efficiency is given by Note the product speed has units of rad/s. The overall efficiency is gives power in units of Nm/s (W) where has a unit of Nm and shaft Alternatively, overall efficiency can also be calculated as Now since the mechanical efficiency is known, we can calculate the theoretical torque as Thus, due to mechanical losses within the pump, 130 Nm of torque are required to drive the pump instead of 114.7 Nm. First we calculate the mechanical input power the electric motor delivers to the pump.

2 Pump input power (kW) isgiven by Next we calculate the electrical input power. Electric motor input power is given by Example 2.14 For the fluid power system of Fig. 2.16, the following data are given: Cylinder piston diameter Cylinder rod diameter Extending speed of cylinder External load on a cylinder Pump volumetric efficiency Pump mechanical efficiency Pump speed Pump inlet pressure 0.203 m 0.102 m 0.0762 m/s 178000 N 92% 90% 1800 RPM 27600 Pa i. The total pressure drop in the line from the pump discharge port to the blank end of the cylinder is 517000 Pa. The total pressure drop in the return line from the rod end of the cylinder = 345000 Pa. Determine the: (a) Volumetric displacement of the pump. (b) Input power required to drive the pump. (c) Input torque required to drive the pump. (d) Percentage of pump input power delivered to the load. ii.

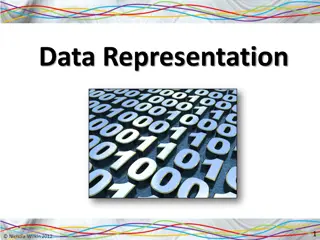

3 Motor Check valve Cylinder F Breather External load Pump Reservoir Directional control Valve Figure 2.16 Solution: (a) Volumetric displacement of pump. = 2.47 LPS Now 0.0000893 (b) Input power required to drive the pump Pump output power = Pump output power = Pump input power = (c) Input torque required to drive the pump

4 Pump input power is Now So torque required to drive pump is T = 100 Nm. (d) Power delivered to load is