Understanding Aseptic Processing and Contamination Control in Cleanroom Environments

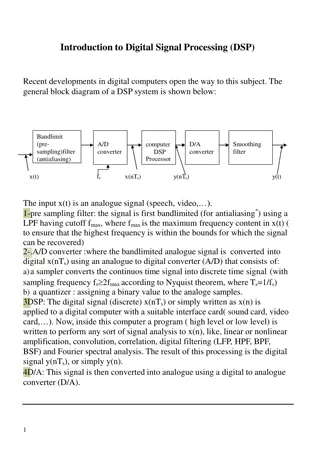

Aseptic processing involves maintaining a sterile environment to prevent contamination in cleanroom settings. The presence of non-viable and viable particulate contamination, such as dust and live microorganisms, poses challenges. Sources of contamination include equipment, structures, surfaces, and human activities. Effective control measures include facility design, proper gowning, behavior, and aseptic techniques. Understanding terms like aseptic, sterile, pathogens, and bio-burden is crucial in ensuring product safety.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Aseptic Processing & PPE

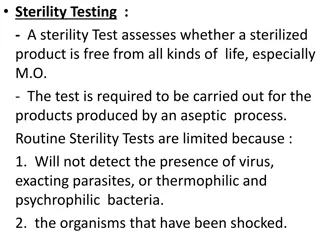

Types of Contamination Two Broad categories of contamination: Non-Viable & Viable - Non-viable particulate contamination is defined as a solid or liquid generally between .001 and 1000 microns in size. -Examples of particulates are dust, fumes, smoke, fogs, and mists. - Viable particulate contamination can be defined as a particle that consists of, or supports one or more live microorganisms. - Bacteria, viruses, and spores are all examples of viable particulate contamination.

Sources of Contamination Many possible sources of cleanroom contamination Equipment, structures, surfaces can all generate particles. Incoming production components can introduce contaminants. People working in cleanrooms generate the most particles. The good news? People can control many of these sources. Estimation: 75% of pharmaceutical product failures due to contamination can be traced directly to improper handling of products and containers by personnel

Controlling Contamination Facility design Personnel AND visitors wear gowns appropriately Personnel AND visitors behave appropriately Aseptic Techniques

ASEPTIC ABSENCE OF MICROORGANISMS THAT CAUSE DISEASE FREEDOM FROM INFECTION FREEDOM FROM CONTAMINATION

STERILE FREE OF MICROORGANISMS, INCLUDING ALL SPORES. STERILISATION THE PROCESS OF KILLING OR INACTIVATING ALL MICROORGANISMS. UNSTERILE INANIMATE OBJECT THAT HAS NOT BEEN SUBJECTED TO A STERILISATION PROCESS.

Related Definitions Pathogens- Organisms often microorganisms that cause disease Bio-burden- Total number of microorganisms on a specific item before sterilization (on components such as containers) Contamination- the presence of unwanted stuff (microbes) on items or in sterile products Parenteral- Medications that move through the body via intravenous or intramuscular injection

Related Definitions (pt. 1) HEPA FILTER High Efficiency Particulate Air Filter controls the particulates and the microorganisms It is able to capture particles of size 0.3 micron or more with a 99.9% accuracy. HVAC- Heating, Ventilation and Air Cooling/Conditioning This system controls the temperature, humidity, air pressure Endotoxins- Product of Gram-negatives, we are always looking to prevent in products. Cause serious adverse events in patients, such as, fevers, shock and even death. Endospores- Spore forming bacteria, they can survive heat, UV. If spores survive the Aseptic Process they can germinate and grow in favorable conditions.

PRINCIPLES OF ASEPTIC TECHNIQUES EFFORTS TAKEN TO KEEP THE PRODUCT AS FREE FROM MICROORGANISMS AS POSSIBLE. IT IS A METHOD USED TO PREVENT CONTAMINATION

HOW?? THROUGH ENSURING THAT ONLY STERILE EQUIPMENTS AND TECHNIQUES ARE USED DURING ALL PROCEDURES HANDLING PLASMA & THE PRODUCTS

Principles of Aseptic Techniques (pt. 1) Proper aseptic techniques is one of the most fundamental and essential principles of contamination control in a Biotech manufacturing. Aseptic Techniques are those which: Remove/reduce or kill microorganisms from hands and objects Employ sterile instruments and other items Reduce patients risk of exposure to microorganisms that cannot be removed

Principles of Aseptic Techniques (pt. 2) Aseptic technique also encompasses practices performed immediately before and during a procedure to reduce contamination: Hand washing Scrub, sterile gowning & gloving Using barriers and PPE Maintaining a Sterile Field Using safe techniques Maintaining a safe environment

PRINCIPLES OF ASEPTIC TECHNIQUES (pt 1) All articles used for during procedures are sterilized prior to use. Gowns are considered sterile only from waist to shoulder level in front and sleeves. Personnel who are sterile only touch sterile articles; Personnel who are not sterile only touch unsterile items. Sterile touching sterile remains sterile. Sterile touching unsterile contaminates all.

PRINCIPLES OF ASEPTIC TECHNIQUES (pt. 1) Arms not to be folded under axillae. If in doubt about the sterility of any item, consider it unsterile. Non-sterile personnel must avoid reaching over a sterile field, sterile personnel must avoid leaning over a sterile field. Sterile personnel must be close to the sterile area, unsterile personnel must be away from the sterile area.

PRINCIPLES OF ASEPTIC TECHNIQUES (pt. 2) Moisture may cause contamination. Pouring should be done at the edge of the table. When passing in a sterile field, remember sterile to sterile. Sterile area must be kept insight all the time. Avoid coughing, sneezing or unnecessary talking over a sterile field.

What is Aseptic Processing? (pt. 1) Processing of the finished product to remove bio-burden Often when terminal sterilization cannot be used because of degradation

What is Aseptic Processing? (pt. 2) The production of sterile drug products by: Bringing together the product, container, and closure that have been subjected to different sterilization methods separately, & Assembling them in an extremely high quality environment by: skilled personnel using the right tools

FDA Regulations 21 CFR 211.28 a) Personnel engaged in the manufacture, processing, packing, or holding of a drug product shall wear clean clothing appropriate for the duties they perform. Protective apparel, such as head, face, hand, and arm coverings, shall be worn as necessary to protect drug products from contamination. b) Personnel shall practice good sanitation and health habits. From Guidance for Industry, Sterile Drug Products Produced by Aseptic Processing Current Good Manufacturing Practice, Sept. 2004: Maintain Proper Gown Control Prior to and throughout aseptic operations, an operator should not engage in any activity that poses an unreasonable contamination risk to the gown.

Definition and Attributes Provides a barrier Filtration system GMP Requirement Maybe compromised by: Coughing Sneezing Talking Excessive movement Excessive sweating Improper cleanroom behavior

Best Practices Personal Hygiene Bathe daily Wash hands after rest room use / before and after meals Wear clean clothing Keep fingernails short and clean No nail polish or false nails Practice good skin care keep skin moisturized

The Basics Aseptic Gowning Good personal hygiene Remove jewelry / watches No bare skin below waist Socks must cover your ankles NO ANKLE SOCKS NO COSMETICS Communicate illnesses / health conditions with supervisor

Gowning Level Summary Level I Level II Level III Hairnets X X X Beard Covers X X X Shoe Covers X X X Safety Glasses X X X Gloves X X X Plant Uniform X X X Lab Coat Plant Shoes or another pair of Shoe Covers X X Sterile Gloves X X Sterile Mask X X Sterile Hood X X Sterile Coverall X X Sterile Boots X X Sterile Gloves X X Sterile Sleeves X

Gowning for Controlled Areas Pay attention to posted signage Check gowning in mirrors Gown appropriately Help each other out

COMMON GOWNING ERRORS Hair protruding from bouffant. Ears not covered. Open collar on frock. Gloves rolled up and/or frock sleeves pulled back from gloves. The gloves should be fully extended up the forearms. Once again, the reason for gowning is to expose a minimum of flaking skin, hair, etc. that could harm your work.