Understanding Fermenter Design and Functionality

The fermenter is essential in the fermentation process, providing a controlled environment for biomass and product yields. It enables aseptic fermentation, optimal mixing, and aeration without excessive power consumption. Key functions include temperature control, pH regulation, and minimizing evaporation losses. The design should allow easy sampling, monitoring, and maintenance while accommodating a variety of fermentation processes within containment regulations.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

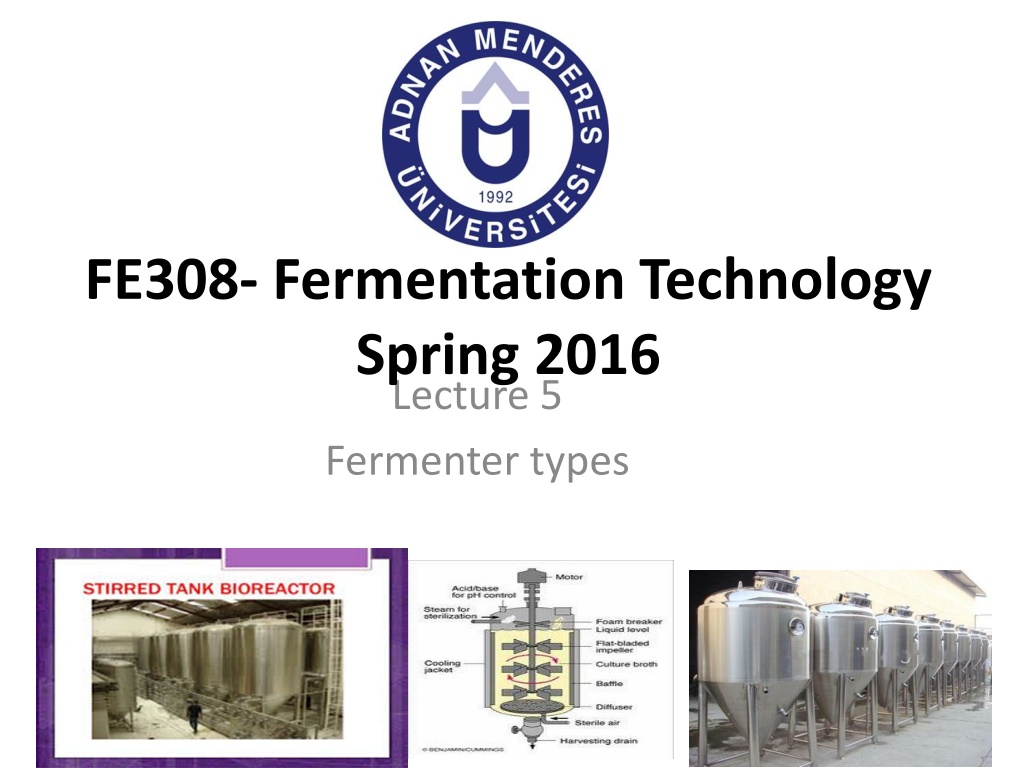

FE308- Fermentation Technology Spring 2016 Lecture 5 Fermenter types

Fermenter The heart of the fermentation process is the fermenter. In general: Stirred vessel, H/D 3 Volume 1-1000 m3(80 % filled) Biomass up to 100 kg dry weight/m3 Product 10 mg/l 200 g/l 2

Required value generation in fermenters as a function of size and productivity 4

Various components of an ideal fermenter for batch process are: 6

Basic Functions of a Fermenter 1. It should provide a controlled environment for optimum biomass/product yields. 2. It should permit aseptic fermentation for a number of days reliably and dependably, and meet the requirements of containment regulations. Containment involves prevention of escape of viable cells from a fermenter or downstream processing equipment into the environment. 3. It should provide adequate mixing and aeration for optimum growth and production, without damaging the microorganisms/cells. The above two points (items 2 and 3) are perhaps the most important of all. 4. The power consumption should be minimum. 5. It should provide easy and dependable temperature control.

6. Facility for sampling should be provided. 7. It should have a system for monitoring and regulating pH of the fermentation broth. 8. Evaporation losses should be as low as possible. 9. It should require a minimum of labour in maintenance, cleaning, operating and harvesting operations. 10. It should be suitable for a range of fermentation processes. But this range may often be restricted by the containment regulations.

Fermenter Design A bioreactor is a device in which a substrate of low value is utilized by living cells or enzymes to generate a product of higher value. Bioreactors are extensively used for food processing, fermentation, waste treatment, etc. On the basis of the agent used, bioreactors are grouped into the following two broad classes: (i) Those based on living cells (ii) Those employing enzymes. But in terms of process requirements, they are of the following types: (i) Aerobic (ii) Anaerobic (iii) solid state (iv) immobilized cell bioreactors.

Theoretical explanation usually lags behind technical realization. A bioreactor should provide for the following: Agitation Aeration Agitation The medium must be suitably stirred to keep the cells in suspension and to make the culture homogeneous; it becomes increasingly difficult with the scaling up. Various types of stirrers range from simple magnetic stirrers, flat blade turbine impellers, to marine impellers, to those using pneumatic energy, e.g., airlift fermenter, and those using hydraulic energy, e.g., medium perfusion.

Aeration Aeration may be achieved by medium perfusion, in which medium is continuously taken from culture vessel, passed through an oxygenation chamber and returned to the culture. The cells are removed from the medium taken for perfusion so that the medium can be suitably altered, e.g., for pH control. Perfusion is used with glass bead and, more particularly, with micro-carrier systems. The following components of the fermenter are required for aeration and agitation: (i) agitator (impeller) (ii) stirrer glands and bearings (iii) Baffles (iv) sparger (the aeration system).

1. Agitator (Impeller): Agitators achieve the following objectives; (a) Bulk fluid and gas-phase mixing (b) Air dispersion (c) Oxygen transfer (d) Heat transfer (e) Suspension of solid particles (f) Maintenance of a uniform environment throughout the vessel.

These objectives are achieved by a suitable combination of the most appropriate agitator, air sparger and baffles, and the best positions for nutrient feeds, acid or alkali for pH control and antifoam addition. Agitators are of several different types: (i) Disc turbines (ii) Vaned discs (iii)Open turbines of variable pitch (iv)Propellers.

2. Stirrer Glands and Bearings: The satisfactory sealing of the stirrer shaft assembly has been one of the most difficult problems; this is very important for maintaining aseptic conditions over long periods. Four basic types of seal assembly have been used in fermenters: (1)The stuffing box (packed- gland seal) (2)The simple bush seal (3)The mechanical seal (4)The magnetic drive.

Stirrer Glands and Bearings A. Scaba agitator, B. Lightning A315 agigator, C. Prochem Maxflo T agigator

3. Baffles: Baffles are metal strips roughly one-tenth of the vessel diameter and attached radially to the fermenter wall.They are normally used in fermenters having agitators to prevent vortex formation and to improve aeration efficiency Usually, four baffles are used, but larger fermenters may have 6 or 8 baffles. Extra cooling coils may be attached to baffles to improve cooling. Further, the baffles may be installed in such a way that a gap exists between the baffles and the fermenter wall. This would lead to a scouring action around and behind the baffles, which would minimise microbial growth on the baffles and the fermenter wall.

4. Aeration System (Sparger): The device used to introduce air into the fermenter broth is called sparger. Spargers are of the following three basic types: (1) Porous spargers (2) Orifice spargers (3) Nozzle spargers. Porous spargers may be made of sintered glass, ceramics or a metal.

Temperature Regulation: The fermenter must have an adequate provision for temperature control. Both microbial activity and agitation will generate heat. If this heat generates a temperature that is optimum for the fermentation process, then heat removal or addition may not be required. But in most cases, this may not be the case; in all such cases, either additional heating or removal of the excess heat would be required. Temperature control may be considered at laboratory scale, and pilot and production scales. The heating/cooling requirements for a specific fermentation process can be accurately estimated by taking into account the overall energy balance of the process, which is described by the following formula. Qmet+ Qag+ Qgas= Qacc+ Qexch+ Qevap +Qsen

where, Qmet the rate of heat generated by microbial metabolism; Qag= the rate of heat produced by mechanical agitation; Qgas= the rate of heat generated by aeration power input; Qacc= the rate of heat accumulation in the system; Qexch= the rate of heat transfer to the surroundings and/or heat exchanger, i.e., heating/cooling device; Qevap= the rate of heat loss due to evaporation; and Qsen= the rate of sensible enthalpy gain by the flow streams (exit-inlet). This equation may be arranged as follows. Qexch= Qmet+ Qag+ Qgas Qacc Qsen Qevap In this equation, Qexchprovides the estimate of heat that has to be removed by the cooling system. The values for Qmetare experimentally determined for different substrates, while those of Qag, Qgas, Qevap,and Qsenare computed using appropriate methods/formulae.

Foam Control: Foam is produced during most microbial fermentations. Foaming may occur either due to a medium component, e.g., protein present in the medium, or due to some compound produced by the microorganism. Proteins are present in corn-steep liquor, pharma media, peanut meal, soybean meal, etc. These proteins may denature at the air-broth interface and form a protein film that does not rupture readily. Foaming can cause removal of cells from the medium; such cell wills undergo autolysis and release more proteins into the medium. This, in turn, will further stabilize the foam.

Five different patterns of foaming are recognized; these are listed below. 1. Foaming remains at a constant level throughout the fermentation. Initial foaming is due to the medium, but later microbial activity contributes to it. 2. Foaming declines steadily in the initial stages, but remains constant thereafter. This type of foaming is due to the medium. 3. The foaming increases after a slight initial fall , in this case, microbial activity is the major cause of foaming. 4. The foaming level increases with fermentation duration; such foaming pattern is solely due to microbial activity. 5. A complex foaming pattern that combines features of two or more of the above patterns.

Ideal antifoam should have the following properties. 1. It should disperse rapidly and act fast on existing foam. 2. It should be used at a low concentration. 3. It should prevent new foam formation for a long time. 4. It should not be used up or degraded by the microorganism. 5. It should be nontoxic (to the microorganism as well as animals, including humans). 6. It should not interfere with downstream processing. 7. It should not cause problems in effluent treatment. 8. It should be safe to handle. 9. It should be cheap. 10. It should not affect oxygen transfer.

Types of Fermenters: Stirred Tank Fermenter: These are glass (smaller vessels) or stainless steel (larger volumes) vessels of 1-1,000 1 or even 8,000 1 (Namalva cells grown for interferon; but in practice their maximum size is 20 1 since larger vessels are difficult to handle, autoclave and to agitate the culture effectively). These are closed systems with fixed volumes and are usually agitated with motor-driven stirrers with considerable variation in design details, e.g., water jacket in place of heater type temperature control, curved bottom for better mixing at low speeds, mirror internal finishes to reduce cell damage, etc. Many heteroploid cell lines can be grown in such vessels.

Airlift Fermenter: An airlift fermenter consists of a gas light baffled riser tube or draught tube (broth rises through this tube) connected to a down-comer tube (broth flows down through this tube). The riser tube may be placed within the down-comer tube as shown in Fig. 14.4, or it may be externally located and connected to the latter (Fig. 14.5). Air/gas mixture is introduced into the base of the riser tube by a sparger. The aerated medium/broth of the riser tube has a lower density, while that in the down-flow tube it is relatively much less aerated and, as a consequence, has a higher density. This density difference drives the circulation of broth. The lighter medium in the rise tube flows upward till it reaches the gas disengagement space of the fermenter. The O is continuously consumed by the cells and CO is

Air-lift fermenter with externally placed riser tube Air-lift fermenter with inner loop

A Schematic diagram of the Air-lift fermenter used by Marlow Foods

This air-lift fermenter of 43 m3volume is used in a continuous mode for the production of mycoprotein Quorn from Fusarium gaminareum grown on wheat starch-based medium. It allows production of long hyphae due to low shear, which is the preferred form of the product. However, it gives lower biomass yields (only 20 g l-1) due to lower oxygen transfer rates in the high viscosity broth resulting from fungal hyphae. This fermenter is a modification of that designed by ICI pic, U.K. for SCP production using methanol as substrate. The fermenter was developed to reduce production costs by minimising cooling costs since agitated vessels would generate additional heat. ICI pic used it in a continuous process to produce SCP for animal feed, but the process had to be discontinued because of high methanol cost and competition from animal feeds based on protein-rich crop produce. The mycoprotein production is, however, primarily for animal food.

A Sxhematic representation of an Airfit fermentor Animal cell cultures are also grown in such vessels that are both aerated and agitated by air bubbles introduced at the bottom of vessels (Fig. 14.7). The vessel has an inner draft lube through which the air bubbles and the aerated medium rise since aerated medium is lighter than non- aerated one; this results in mixing of the culture as well as aeration. The air bubbles lift to the top of the medium and the air passes out through an outlet. The cells and the medium that lift out of the draft tube move down outside the tube and are re-circulated. O2supply is quite efficient but scaling up presents certain problems. Fermenters of 2 90 1 are

Tower Fermenter: A tower fermenter has been defined by Green- shields and co-workers as an elongated non- mechanically stirred fermenter that has an aspect ratio (height to diameter ratio) of at least 6 : 1 for the tubular section and 10 ; 1 overall, and there is a unidirectional How of gases through the fermenter. There are several different types of tower fermenters, which are grouped as follows on the basis of their design: (1) Bubble columns (2) Vertical-tower beer fermenter (3) Multistage fermenter systems.

1. Bubble Column Tower Fermenters: These are the simplest type of tower fermenters; they consist of glass or metal tubes into which air is introduced at the base. Fermenter volumes from 3 / to up to 950 / have been used, and the aspect ratio may be up to 16 : 1. These tower fermenters have been used for citric acid and tetracycline production, and for a range of other fermentations based on mycelial fungi. 2. Vertical-Tower Beer Fermenters: These fermenters were designed for beer production and to maximise yeast biomass yields. A series of perforated plates are placed at intervals to maximise yeast yields. It has a settling zone free of gas; in this zone, yeast cells settle down to the bottom and return to the main body of the tower fermenter, and clear beer could be removed from the fermenter. Tower of up to 20,000 / capacity and capable of producing up to 90,000 I beer per day have been installed.

3. Multistage Tower Fermenters: In these fermenters, a column forms the body of vessel, which is divided into compartments by placing perforated plates across the fermenter. About 10% of the horizontal area of plates is perforated. In a variant of this type of fermenter (down-flow tower fermenter), the substrate is fed in at the top and overflowed through down spouts to the next section, and the air is supplied from the base. These fermenters have been used for continuous culture of E. coli, S. cerevisiae (baker s yeast), and activated sludge.

Bubble-up Fermenter: It is a bubble column fermenter that is fitted with an internal cooling coil (Fig. 14.8). Air is introduced from the bottom of the column. In this vessel, the cooling coil effectively separates the column into an inner riser/draught tube and the outer down-flow tube. The cooling coil assembly functions as a leaky draught tube. The culture broth rises in the compartment enclosed by the cooling coils and it moves down in the compartment outside the coil, although back- mixing also occurs through the coils. The region above the cooling coil shows good mixing, and there were no poorly oxygenated zones in the vessel.

These are the simplest type of tower fermenters; they consist of glass or metal tubes into which air is introduced at the base. These tower fermenters have been used for citric acid and tetracycline production, and for a range of other fermentations based on mycelial fungi.