Equipment Selection and Management in Food Service

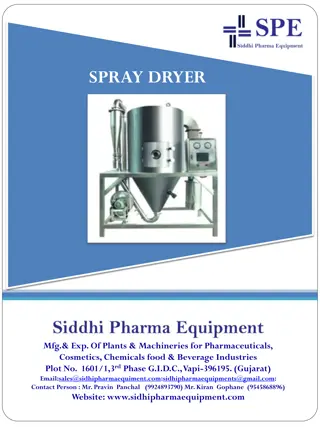

The content discusses the key factors to consider when selecting equipment for food service management, such as size, menu, usability, design utility, pricing, maintenance, safety, economy, cleaning ease, and more. It emphasizes the importance of choosing equipment that aligns with the specific needs of the establishment, ensuring safety, efficiency, and cost-effectiveness.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Subject Title : FOOD SERVICE MANAGEMENT-II Subject Code : 16SCCND9

SELECTION OF EQUIPMENT 1.Size &type of est. 2.Menu 3.Usuage 4.Utility in terms of design & frequency of use. 5.Price. 6.Ease of installation ,maintenance & operation . 7.Safety. 8.Economy. 9.Ease of cleaning. 10.Attractiveness. 11. Source of supply.

SIZE &TYPE OF EST. Plan for 5 to 10 year, Space measurement Too large-inefficient utilization Too small-will not be able to meet the demands of the customer In small size est.-mobile &flat packed &stored when not in use The equipment which is designed so that parts of one can be used inter changeably with another This referred as MODULAR EQUIPMENT Small & medium size- multifunction equipment EX; griddles which used for making dosa. MENU. No.of hot foods , portions, peak times method of cooking If the institute is bakery then no need for fryer If ready mixed idly & dosa purchased then no need for wet grinder. ATTRACTIVENESS Attract to workers & create a desire for using. SOURCE OF SUPPLY Must be checked for guarantee, safety, seals & labels.

USUAGE Should fulfill specific purpose ,in terms of production, profitibility & convenience UTILITY OF DESIGN Maintaining the temperature to keep food safe. Should have temperature indicators & warning lights. Frequency of use, mobility of equipment, ease of cleaning. PRICE Always determines & buying choice. The investment cost of an equipment should be careful in terms of quantity & quality of the product, saving labour & time, maintenance charge of equipment. The investment rate should be get returned . Selecting of equipment is based on available funds to the buyer. EASE OF CLEANING Selected equipment should be Non-corrosive, non-toxic, non-absorbent, stable to heat & moisture Should have smooth surfaces & not requiring any special detergent for cleaning.

EASE OF INSTALLATION, MAINTAINCE & OPRATION. Construction of equipment should be simple. Easy to access with skills of catering staff (easy to learn) Should be hygienic & safety. If the operating procedure is long write the steps to follow in simple terms & pasted on door. SAFETY Catering equipment deals with heavy equipment, sharp tools, glass, cutlery, electricity, gas, hot, &cold water. so, the equipment should be guaranteed for safety while in operation & not in use. Free from dirt, dust. ECONOMY Amount of fuel electricity, gas, coal. In some areas, electricity may be better. In some, pressure cooking. In some, micro ware oven. Higher initial cost & lower maintenance cost wiser to select. The availability of space parts.

PURCHASING EQUIPMENT Act of buying at price PURCHASING is a management activity which involves planning, policy-making & conducting research & development activities required for proper selection of materials & sources of purchase to ensure proper delivery & inspection for quality. The sources of supply can get from, Past experience, interviewing sales man, equipment catalogues, quotations PURCHASE PROCEDURE a) The recognition of a need b) Specification of the required item c) Selection of sources of supply d) Enquires regarding the price e) Placing the order f) Following up the order g) Checking the equipment & invoices h) Maintaining records & files

PURCHASING METHODS 1.IN-FORMAL & OPEN MARKET BUYING Used by small establishments Buyer & supplier contact directly by telephone Price quotations are obtained informally 2.FORMAL COMPETITIVE BID BUYING Equipment to be purchased are written out & quotations are invited from sellers ( Advertising in daily news papers) Sealed quotations opened in the presence of sellers Then formally accepted which is most suitable one & orders placed All bids(tenders) should state date, method of delivery, terms of payment, Willingness to accept, discount & date of closing bids. 3.NEGOTIATED BUYING This method is flexible, & make fast purchasing The buyers request sellers to submit bids in writing format Semi formal method Less strict in their procedure for acceptance.

4.AUCTION BUYING Used for spot purchasing No. of bidders but no formal contract No responsibility & guarantee offered by the seller Payment generally in cash, which is paid on the spot Advantages of the buyer is Initial low price Immediate delivery Ability to inspect before purchasing 5. BLANKET ORDER PURCHASING Good method for purchasing single item Not too expensive ex: crockery, cutlery, knives, ladles.. Agreement with the supplier to provide items for a period of time at an agreed price . Advantages Variety of items can be purchased from one supplier & deliveries are on time Less paper work Possible to buy at lower price , discounts

6. CONSIGNMENT BUYING 0R STOCKLESS PURCHASING The supplier who are nearest the location (seller) Requiring items frequently at irregular intervals Advantages No capital investment on stock is minimized Paper work, time, effort reduced. PAYMENT FOR EQUIPMENT Installment payment Advance payment (full payment on delivery) Payment settled mutually between buyer and seller 25 % payment when ordering the item.

CARE & MAINTENANCE OF THE EQUIPMENT All equipments requires care in handling, use & storage to extend its life to maximum. Small pieces like cutlery, crockery need less care than others Knives, choppers blade should be prevent from rusting Whisks & beaters should wash immediately after use. Wash all removable parts with suitable detergent & hot water After washing wipe equipment & dry before replacing. Repairs must be attended without delay Oiling & servicing of equipment frequently Periodic checking for running of the equipment Assign the care of each machine to one responsible persons Maintaining equipment in continuous working order Maintaining records also helps to detect inefficiencies in operation. Thus if equipments cared for systematically it prolongs the life of the equipment.

BASE MATERIALS USED IN EQUIPMENT COPPER Used in manufacture of cooking utensils Excellent heat conductivity properties Now a days the copper bottom used in stainless steel vessels Which is light in weight & cheaper to buy However, metal is expensive & requires frequent polishing for maintenance. ALUMINIUM More easily manufacture than copper Used in storage bins, trays, cooking equipment & utensils Light in weight with high thermal, Electrical conductivity Durable, hard & non-corrosive Dis advantage: Easily get discoloured ANODISED ALUMINIUM Manufactured to harden the surface of the equipment Resistance to oxidation, discolouration & scratching Used in mobile equipment, used as base in non-stick equipment, baking trays Advantage: Easy cleaning.

POLYETHYLENE Drums & barrels made of high molecular weight,high density polyethylene (HM-HDPE) are available for storage. Used for store oils, liquids & dry storage food. ADVANTAGES; Light &easy to handle. Less expensive than steel drums. Longer life . Leak proof. Non-corrosive & rust proof. Hold up to 110 degree celcius. Reusable & resaleable. Hygienic & washable.

GALVANIZED STEEL&IRON. Used in kadai, griddles, frying pans & cooking ranges. Coated with zinc on base of the metal which makes resistant to corrosion. Original cost is low but replacement &repair cost are high. It has short life. Unattractive. NON-CORROSIVE MATERIALS. Alloys of nickel, copper, stainless steel. Another metal is known as monal metal It is natural alloy containing nickel &copper 2:1 with small amounts of iron. Heavy duty kitchen equipment, cooking utensils & table ware are manufactured by iron, nickel, chromium. The usage has increased in institutional kitchens , B.coz. easy fabrication, non-corrosion ,reasonable price. Attractive , easy to clean ,resistant to strains.

CHORME Nickel stainless steel alloy called 18-8 18% chromium.8%.nickel with no copper Easy to clean &maintain. Used in f.s.e for rougher handling. SILVER PLATE. Silver plate equipment or (EPNS)Electro Plated Nickel Silver Used for service. Difficult to maintain & requires frequent polishing It s not economical hence can not use in small & medium est.

GLASS OR CERAMIC Suitable for service equipment ,(tea, coffee pots, in oven) Glass materials resistant to corrosion. Heat resistant glass (borosil, pyrex,) which directley heat & served with same equipment. MUD POTS: 1. Used traditionally (curds &other beverages) 2. Can see in read side stall 3. This provides eco friendly alternatives for glass, cermiec, steel..