Understanding Transformer Windings: A Comprehensive Guide

This comprehensive guide delves into the intricacies of transformer windings, explaining the concepts of turns, coils, and windings in detail. It covers the different types of windings, materials used, and considerations for designing windings, providing valuable insights for anyone interested in electrical machines and transformers.

Uploaded on Sep 29, 2024 | 0 Views

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Types of Types of Types of Transformer Transformer Transformer Oil Transformer Windings Windings Windings PRESENTED BY PROF. VG PATEL VG PATEL

TRANSFORMER ENCYCLOPAEDIA TYPES OF TRANSFORMER WINDINGS WINDING Winding is an assembly of turns which constitutes an electrical circuit. Turn is the formation of a conductor over the core in which an emf is induced and it is enclosed by magnetic flux. The word conductor can be use in more abstract sense as winding current carrier. When two conductors are connected with proper polarity, emf induced in each conductor will be added and is known as TURN. Many turns connected with proper polarity, emf induced in each turn will be added and is known as COIL. Many coils connected with proper polarity, emf induced in each coil will be added and is known as WINDING. Winding is the conducting part of the transformer. VG PATEL Sunday, September 29, 2024 2

TRANSFORMER ENCYCLOPAEDIA TYPES OF TRANSFORMER WINDINGS CONDUCTING SYSTEM OR WINDINGS For designing winding or coil, the designer may choose any arrangement by considering the following aspects: Effective Die-electric strength against various types of voltages, system fault, switching surges, lightning surges and test voltages. Cooling of coil. Adequate mechanical strength & Minimum Cost. Good weldability, solderability and brazing which ensures high reliability and low electrical resistance of the joints. VG PATEL Sunday, September 29, 2024 3

TRANSFORMER ENCYCLOPAEDIA TYPES OF TRANSFORMER WINDINGS Material of high conductivity is used for making conductors for all kinds of windings required in electrical machines. These materials should have the least electrical resistivity. The basic material used for transformer windings is the insulated copper or aluminium wire of round or rectangular cross section and these can be employed in various forms, depending on current and voltage requirements. Generally Copper conductors are used as it is having good electrical and mechanical strength. The windings are manufactured with high level of techniques after thoroughly examining insulation structure, cooling method and mechanical strength. The shape of the winding conductor in power transformers is usually rectangular in order to utilize the available space effectively. Sunday, September 29, 2024 VG PATEL 4

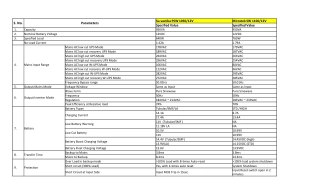

TRANSFORMER ENCYCLOPAEDIA TYPES OF TRANSFORMER WINDINGS Types of Windings: 1. Cross-over Winding 2. Spiral winding: (i) Single layer 3. Helical winding: (i) Single Helical (ii) Double Helical (iii) Multistart Helical 4. Disc winding: (ii) Interleaved disc winding 5. Inter-Shield winding 6. CTC Winding 7. Eight shaped Winding 8. Foil winding 9. Composite winding Sunday, September 29, 2024 (ii) Double layer (iii) Multi start (iv) Edge winding (i) Continuous disc winding VG PATEL 5

TRANSFORMER ENCYCLOPAEDIA TYPES OF TRANSFORMER WINDINGS CROSS OVER TYPE WINDING Cross over type winding is same as cylindrical winding, mainly used as high voltage winding, where current rating is up to 30 amperes and voltages up to 33 kV in distribution transformers. It is wound with round wires with paper insulation or enamel coating on conductors. The winding have high short circuit strength. The winding having good mechanical strength and also economical in design has lower impulse strength. VG PATEL Sunday, September 29, 2024 6

TRANSFORMER ENCYCLOPAEDIA TYPES OF TRANSFORMER WINDINGS SPIRAL WINDING Spiral winding is mainly used for low voltage winding when the current rating is up to 3500 amperes and voltage rating up to 3.6 kV. Spiral winding is also called cylindrical winding or layer type winding. Winding using rectangular conductors may be wound with one or more parallel conductors placed radially as well as axially. Single and multi layer winding are used mainly for small and medium size transformer. For large transformers, this type is used for regulating winding. VG PATEL Sunday, September 29, 2024 7

TRANSFORMER ENCYCLOPAEDIA TYPES OF TRANSFORMER WINDINGS HELICAL WINDINGS The helical winding (Helix Winding) is suitable for high currents, where the current is shared between several parallel conductors. The dimensions of each conductor can be kept reasonably small in order to keep the eddy current losses low. It is said that helical windings have a high space factor, which is beneficial for an overall total mass-total loss relation. Moreover, it is mechanically robust and easy to manufacture, particularly when continuously transposed conductor is used. Helix winding has three types of winding: a) Single helical b) Double helical c) Multilayer helical VG PATEL Sunday, September 29, 2024 8

TRANSFORMER ENCYCLOPAEDIA TYPES OF TRANSFORMER WINDINGS HELICAL WINDINGS Single Helical windings are used for LOW VOLTAGE- MEDIUM and HIGH CAPACITY transformer where the no. of winding turns are small but the current is high. The current rating of Single helical winding is 1200 amperes (maximum) The conductor is rectangular in cross section and is paper covered The double helical winding is used in low voltage winding of high power ratings where the number of winding turns is small and a single helical winding with normal width of oil ducts does not fill up properly a window height, while the current and the no. of parallel conductor required are very large. The current rating of the double helical winding is twice that of single helical winding Multilayer Helical Winding consists of several cylindrical layers concentrically wound and connected in series. It is used for tapping. VG PATEL Sunday, September 29, 2024 9

TRANSFORMER ENCYCLOPAEDIA TYPES OF TRANSFORMER WINDINGS DISC TYPE WINDINGS Disc type windings are generally used in H.V. winding for Power and Distribution transformers. Disc winding is generally of two types a) Continuous disc winding. b) Interleaved disc winding Continuous disc winding is primarily used in high capacity transformer. The continuous disc winding is mainly used as high voltage from 6.6 to 66 kV To overcome the low series capacitance in continuous disc winding, earlier electrostatic shield was provided till the approval of the interleaved winding. It is generally used in high voltage winding having voltage class of 110 kV above. This winding also called high series capacitance winding. Sunday, September 29, 2024 VG PATEL 10

TRANSFORMER ENCYCLOPAEDIA TYPES OF TRANSFORMER WINDINGS SHIELDED DISC TYPE OR INTER-SHIELD WINDING It is generally used in HV winding having voltage class above 110 kV. By shielded disc type winding, is improved seriescapaci- tance and also less labour intensive as compared to as interleaved winding. There are some disadvantages: Decrease in winding space factor. Requirement of extra winding material used as shield. Possibility of disturbance in ampere turn balance per unit height of LV and HV winding and extra eddy current loss in shields. VG PATEL Sunday, September 29, 2024 11

TRANSFORMER ENCYCLOPAEDIA TYPES OF TRANSFORMER WINDINGS CTC (CONTINUOUSLY TRANSPOSED CON- DU CTOR) WINDING There has been a tremendous increase in the demand for electrical power, these days. This situation calls for a commensurate increase in the power rating and operating voltage of electrical power system. The transformers used in power system are now required to withstand higher electrical, mechanical and thermal stresses. The development of CTC has provided the transformer industry a winding material that can be used for ever rising system. VG PATEL Sunday, September 29, 2024 12

TRANSFORMER ENCYCLOPAEDIA TYPES OF TRANSFORMER WINDINGS CTC (CONTINUOUSLY TRANSPOSED CON- DUCTOR) WINDING The winding constructed with CTC have been found beneficial for high voltage high power transformer. CTC used for transformer winding has high thermo-mechanical strength, excellent insulation characteristics and low stray load loss. The stray losses in the large transformer using conventional configuration for the conductor tend to be high. Therefore a need arises to decrease these losses by suitably designing the winding of transformer. VG PATEL Sunday, September 29, 2024 13

TRANSFORMER ENCYCLOPAEDIA TYPES OF TRANSFORMER WINDINGS ADVANTAGES OF CTC: The stray load loss is reduced, since CTC is manufactured using large number of conductor strips which are continuously transposed. The use of CTC reduces the overall size of transformer on account of strands and consequent reduction in the weight of core, winding, tank and oil. The winding time reduced due to use of assembled transposed conductor in place of parallel strips. The winding has an improved mechanical strength due to composite construction of the transposed conductor. The individual strips use thin enamel insulation, therefore cooling of the conductor is improved on account of increased heat dissipation. The conductors have an increased mechanical strength. Sunday, September 29, 2024 VG PATEL 14

TRANSFORMER ENCYCLOPAEDIA TYPES OF TRANSFORMER WINDINGS EIGHT-SHAPED WINDING We can say that by using eight-shaped winding we can have following advantages: In a furnace transformer like this, we can use OLTC instead of OCKT. We can get voltage in the regular steps of intervals. It reduces the overall size of the transformer, so as tank, oil etc. Stray losses is reduced by using CTC. VG PATEL Sunday, September 29, 2024 15

TRANSFORMER ENCYCLOPAEDIA TYPES OF TRANSFORMER WINDINGS FOIL WINDING Foil windings are widely applied in low voltage winding of distribution transformer. In this type of winding, aluminium or copper can be used as a material for conductors. The main technical advantage is that axial mechanical forces acting on the windings in the transformer during short circuit currents become insignificant, because, inducted eddy currents in the foil weaken the radial component of the magnetic leakage field at the top and the bottom of the winding. VG PATEL Sunday, September 29, 2024 16

TRANSFORMER ENCYCLOPAEDIA TYPES OF TRANSFORMER WINDINGS COMPOSITE WINDING Composite winding is the winding of LV, HV and Regulating coils (or any two) done one - by - one on single former without removing coil(s). i.e. first LV coil is wound and then HV coil is wound after providing appropriate insulation in between LV & HV coils. Also sometimes first HV coil is wound and then HV Regulating coil is wound on the same former without removing coil from the former. VG PATEL Sunday, September 29, 2024 17

TRANSFORMER ENCYCLOPAEDIA TYPES OF TRANSFORMER WINDINGS COMPOSITE WINDING Advantages: Assembly time period is reduced. Crane availability increased. Former removal time reduced. No possibility of mistake of lead position. Saving in time for ovening and pressing(only 3 coils). Insulation between HV & LV is done on winding machine. Less space is occupied (own and shop-floor). Less man power. VG PATEL Sunday, September 29, 2024 18

TRANSFORMER ENCYCLOPAEDIA TYPES OF TRANSFORMER WINDINGS COMPOSITE WINDING Disadvantages: If lead position is wrong for LV, will be wrong for HV also. For LV fault, HV coil also will have to be removed. For wrong dia of LV, HV dia will also be wrong. Cycle time of winding will increase (2 or 3 m/cs will be engaged). Coil lifter jaws length would be more (500 / 600 mm), may bend. Good up to medium transformer (normally for Distribution Trans.). Weight, Radial thickness, Height, Diameter, Crane capacity all to be considered. VG PATEL Sunday, September 29, 2024 19

TRANSFORMER ENCYCLOPAEDIA OPEN FORUM Sunday, September 29, 2024 20

TRANSFORMER ENCYCLOPAEDIA THANQ Sunday, September 29, 2024 21