Understanding Evaporative Cooling and Cooling Towers in Energy Management

Dive into the world of evaporative cooling and cooling towers with this detailed chapter. Learn about direct and indirect cooling processes, psychrometric phenomena, range and approach in cooling systems, different airflow arrangements in cooling towers, and the theory behind evaporative cooling. Discover the significance of adiabatic saturation, typical system configurations, and essential aspects of cooling tower design.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Introduction to Energy Management

Week/Lesson 9 part a Evaporative Cooling and Cooling Towers

Evaporative Cooling and Cooling Towers After completing this chapter, you will be able to: Distinguish between direct and indirect evaporative cooling processes Understand the psychrometric processes that occur during evaporative cooling processes Define range and approach and how they relate to cooling towers and evaporative coolers

Evaporative Cooling and Cooling Towers Recognize the different arrangements of airflows, fans and sprays within a cooling tower Understand the design and operational differences between cooling towers and evaporative condensers

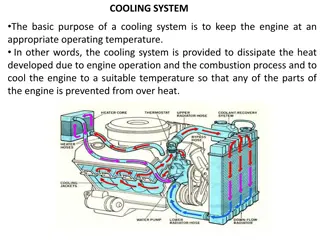

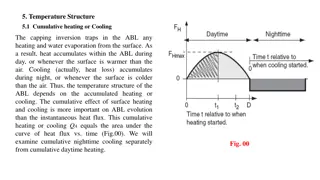

Evaporative Cooling and Cooling Towers Theory of evaporative cooling Evaporative cooling Heat exchanges between water and air Sensible heat is exchanged for latent heat Direct contact or indirect contact Usually both the air and water are cooled

Evaporative Cooling and Cooling Towers Adiabatic saturation No external heat is involved Sensible and latent heat are exchanged Air and water temperatures approach each other No heat transfer occurs when air is saturated

Cooling 7 Pictures from https://rfd-training.tac.com/docs/HVAC.pdf

Evaporative Cooling and Cooling Towers Typical system Water returning to cooling tower = 95 F Water supplied by cooling tower = 85 F The condenser adds about 10 F to the water The cooling tower removes about 10 F from the water

Evaporative Cooling and Cooling Towers Cooling tower design Heat rejected = system heat System heat comes form two sources Heat absorbed by the evaporator Heat produced by the compression process Water flow is about 3 gpm/ton

Evaporative Cooling and Cooling Towers Analysis of a cooling tower s performance Performance affected by WB temperature of entering air Range change in tower water temperature Approach = leaving water temp WB of air Normal approach temperature = 7 to 9 F

Evaporative Cooling and Cooling Towers Example 11-1 Design approach temperature = 7 F WB of the entering air = 68 F Water temperature = WB + Approach Water temperature = 68 F + 7 F Water temperature = 75 F

Evaporative Cooling and Cooling Towers Cooling tower classification and construction Parallel flow Air and water flow in the same direction Air velocity is low Cross flow Water flows from top to bottom Air flows from side to side

Evaporative Cooling and Cooling Towers Counter flow Air flows from bottom to top Water flows from top to bottom Atmospheric (natural) draft tower No fan Forced draft air pulled through the tower Induced draft air pushed through the tower

Evaporative Cooling and Cooling Towers Other tower components Distribution basin top of the tower Water flows through orifices and over fill Spray nozzles can replace the orifices Eliminators limit water loss by blow-by Sump reservoir at the bottom of the tower

Evaporative Cooling and Cooling Towers Water treatment Combats bacteria growth Reduces corrosion and mineral deposits Blowdown cycle Drains a portion of tower water Reduces mineral concentrations

Evaporative Cooling and Cooling Towers Inhibitors Usually painted on the tower surfaces Reduces oxidation Reduces scale formation and buildup Strainers Catch foreign matter in the water Prevent clogging of the water loop

Evaporative Cooling and Cooling Towers Tower control Low ambient conditions Maintains a minimum water temperature Fan control Fan cycles on when water temp is high Fan cycles in order to maintain desired water temperature

Evaporative Cooling and Cooling Towers Valve Control water flow through the tower Low ambient conditions More water bypasses the tower Water temperature is increased High ambient temperatures Little or no water bypasses the tower Water temperature is decreased

Evaporative Cooling and Cooling Towers Damper control air flow through the tower Low ambient conditions Air flow is reduced Water temperature is increased High ambient temperatures Air flow is increased Water temperature is reduced

Evaporative Cooling and Cooling Towers Evaporative condensers Uses both air and water Air flows over the refrigerant coil Water flows over the coil when needed Water remains in the condenser Indirect contact evaporative cooling