Workshop on Energy Efficiency Opportunities in Phasing Down HFCs: Cooling Efficiency Technologies Presentation

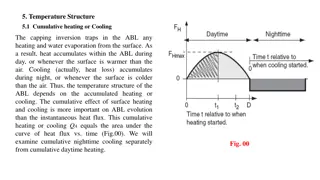

Presentation by Ray Gluckman at a workshop held in Vienna on July 9th, 2018, highlighted the significant potential to improve efficiency in cooling systems while phasing down HFCs. The session covered key principles, examples of efficiency improvements, impact on capital costs, and factors influencing energy use in refrigeration systems. The focus was on achieving the technical potential through better understanding, attention, and monitoring, with comparisons drawn to moving a weight uphill requiring energy.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Workshop on energy efficiency opportunities while phasing-down HFCs Cooling Efficiency: technologies Presentation by Ray Gluckman July 9th2018, Vienna

Presentation Contents Scope for energy efficiency improvements Understanding key efficiency issues efficiency: a step-by-step approach Some examples illustrating: the excellent potential for efficiency improvements impact on capital costs impact of refrigerant selection

Achieving the technical potential there are plenty of opportunities to improve efficiency what is preventing better uptake of the potential? Lack of understanding Lack of attention / effort how to maximise efficiency during design and selection Simplistic financial considerations Lack of monitoring / analysis of performance in operation that ignore the big picture

Some Key Principles during next two sessions we will see many examples of: efficiency improvements related to new equipment (Session II) efficiency improvements related to existing equipment (Session III) to help understand efficiency opportunities what are the key design and operational factors that influence energy use? let s start by comparing a refrigeration system with moving a weight

Moving it back up the hill requires energy The energy required depends on: W 1. The size of the weight, W 2. The height difference, d (the vertical lift ) 3. Practical factors e.g. roughness of the ground d

Refrigeration: moving heat on a thermodynamic mountain Weight Vertical lift = temperature we need to move it through = temperature lift = a quantity of heat we need to move hotter H Temperature colder

If a colder heat sink is available, cooling is free (heat rolls downhill ) e.g. tow an iceberg to a warm city for air-conditioning hotter - not realistic or sustainable! H Temperature colder

But, always worth checking for free cooling options some good possibilities e.g. data centre cooling, especially if located in cool climates food factories hot product pre-cooling after cooking cold process streams that need heating e.g. boiling liquid methane at LNG terminals but less helpful for mainstream RAC applications e.g. domestic refrigerators bulk storage and retailing of chilled or frozen food room air-conditioning in hot countries

Most RACHP applications heat has to move uphill hotter available coolant e.g. ambient air Temperature H cooled product or room colder

Most RACHP applications heat has to move uphill hotter available coolant e.g. ambient air Temperature H cooled product or room colder

How is the heat moved uphill? available coolant H cooled product or room Te

How is the heat moved uphill? Tc hotter available coolant Temperature H cooled product or room Te colder

How is the heat moved uphill? Tc hotter available coolant Temperature cooled product or room H Te colder

How is the heat moved uphill? Evaporating temperature Te must be lower than product temperature Condensing temperature Tc must be higher than the available coolant H Tc hotter available coolant Temperature cooled product or room colder Te

Why is temperature lift so important? RACHP efficiency is VERY sensitive to temperature lift just 1 degree C of extra lift: typically leads to 2% to 4% increase in energy consumption it is very easy to create many degrees C of unnecessary temperature lift through poor design through poor operation incorrect control settings

Recent Press Release 22nd June 2018 India seeks mandatory 24oC AC setting campaign launched by India s energy minister Shri R K Singh he advised: every one degree C increase in AC temperature setting saves 6% many commercial establishments use 18 21 oC set point saving achievable by simply adjusting a control

Reminder: efficiency rules for lifting a weight The energy required depends on: W 1. The size of the weight, W 2. The height difference, d (the vertical lift ) 3. Practical factors e.g. roughness of the ground d

RACHP Heat Mountain Energy Efficiency Rules 1. Minimise the heat load e.g. free cooling better building structure / insulation less cold end auxiliary power (evaporator pumps and fans, lights etc.) less warm air ingress (e.g. doors on display cases) 2. Minimise the temperature lift e.g. These are just a few of the many different measures that may influence design or operational efficiency! bigger heat exchangers changes to temperature set points avoiding fouling of heat exchangers (e.g. frost, oil, debris etc.) 3. Address practical factors e.g. high efficiency compressors high efficiency thermodynamic cycle good performance at part load correct choice of refrigerant Some will be described in Sessions II and II

Example of a practical factor: variable operating conditions RACHP equipment designed for a peak condition the design point highest heat load in highest ambient temperature but equipment spends most of life at other operating conditions if designer ignores the operating envelop of the system it is likely that much energy will be wasted

Impact of efficiency improvement on costs most efficiency measures have a good financial return for end user any extra capital cost often recovered in 1 3 years from energy savings big picture issues can significantly improve financial case potential savings in peak demand and requirements for new power stations value of CO2 emission reductions but, end user has no benefits from these savings some efficiency measures achievable with no extra capital cost or reduced cost especially as efficiency technologies become mature or, if heat load reduced, refrigeration system is smaller (e.g. doors on display cases)

Example of Maturing Technology US Refrigerators from Briefing Note A (figure 7) 75% energy reduction 50% price reduction

Refrigerant Selection good choice of refrigerant is important it is one of the practical factors that influence efficiency selection will typically influence efficiency by 5% to 10% other factors are likely to create greater efficiency improvements e.g. heat load reduction minimising temperature lift good maintenance refrigerant leakage must be avoided can reduce efficiency significantly

Concluding Comments many excellent opportunities to improve RACHP efficiency using a structured approach can help maximise potential based on: 1. Minimising the cooling load 2. Minimising the temperature lift 3. Accounting for variable operating conditions 4. Selecting the most efficient refrigeration cycle, refrigerant and components 5. Designing effective control systems 6. Checking operating performance and correcting any faults

Contact Details Ray Gluckman Gluckman Consulting email: ray@gluckmanconsulting.com Tel: +44 1932 866344 Fact Sheets about Kigali Amendment: www.gluckmanconsulting.com/kigali-amendment/ Fact Sheets about low GWP alternatives to HFCs: www.gluckmanconsulting.com/low-gwp-alternatives-to-hfcs/