Understanding Sedimentation Aided with Coagulation and Flocculation

Sedimentation aided with coagulation and flocculation is a chemical and physical process used in water treatment to efficiently remove impurities and particles. Coagulation involves adding chemicals to neutralize particles, while flocculation helps in forming larger clumps for easier removal. The end result is cleaner water with reduced turbidity. Proper coagulation and flocculation lead to the formation of flocs that settle out in a sedimentation basin. The process is essential for water purification and treatment.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

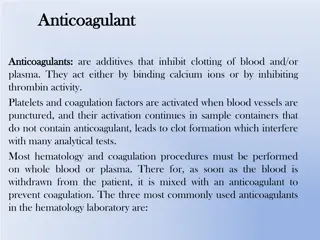

SEDIMENTATION AIDED WITH COAGULATION Coagulation is a chemical process that physically makes sedimentation more efficient. Flocculation is a physical process used to enhance the effectiveness of coagulation's chemical addition. The chemistry of coagulation/flocculation consists of three processes - flash mix,coagulation, and flocculation 1 4/21/2018

SEDIMENTATIONAIDEDWITH COAGULATION In the flash mixer,coagulant chemicals are added to the water and the water is mixed quickly and violently. During coagulation, the coagulant chemicals neutralize the electrical charges of the fine particles in the water,allowing the particles to come closer together and form large clumps. During flocculation, a mixing brings the fine particles formed by coagulation into contact with each other. process of gentle 2 4/21/2018

SEDIMENTATIONAIDED WITH COAGULATION The end product of a well- regulated coagulation/ flocculation process is water in which the majority of the turbidity has been collected into a floc. Larger flocs do not settle as well and are more subject to breakup in the flocculation basin. Smaller flocs also may not settle. 5 4/21/2018

Floc Flocs are clumps of particulate impurities and sometimes bacteria that have come together and formed a cluster. The floc will then settle out in the sedimentation basin, with remaining floc being removed in the filter. The best floc size is 0.1 to 3 mm.

Mostly used Coagulants chemicals with Normal Dose and PH Values Required for Best floc formation 5 4/21/2018

PRINCIPLE OF COAGULATION FLOC FORMATION When coagulants are dissolved in water and mixed with it they produce a thick gelatinous precipitate(floc). The floc has got the property of arresting the suspended impurities in water during downward travel towards the bottom of the tank ELECTRIC CHARGE The ions of floc are found to posses positive eletric charge They will attract the negative charge colloidal particles of clay causing removal of such particles from water 4/21F /2l0o 18cculation is used to denote the process of floc formation

COAGULANTCHEMICALS Coagulant chemicals react with ions naturally found in the water to produce a solid precipitate When coagulants such as Al2(SO4)3are added to the water supply,they form solid precipitates (green), as shown in Equation, above. These precipitates catch other impurities (red) in the water,forming a solid mass containing the precipitate formed by coagulation and the trapped impurities. This mass will settle to the bottom by sedimentation,and the water(with the trapped impurities now removed) can be drained off of the top.

COAGULANTAIDS to improve coagulation; to build stronger, more settleable floc; to overcome the effect of temperature drops that slow coagulation; to reduce the amount of coagulant needed; and to reduce the amount of sludge produced. Polymers, activated silica, adsorbent-weighting agents, and oxidants

PROCESS OPERATION Water characteristics that affect coagulation process include pH, temperature, and ionic strength. Chemical treatment is based on empirical data derived from jar testing or other laboratory tests and field studies 4/21/2018 11

EFFICIENCY OFCOAGULANT Dosage of coagulant Feeding (Powder or in Solution) Mixing speed and period pH value Velocity (floc should move gently after initial quick 4/21/2018 12

FILTRATION The resultant water after sedimentation will not be pure, and may contain some very fine suspended particles and bacteria in it. To remove or to reduce the remaining impurities still further, the water is filtered through the beds of fine granular material, such as sand, etc.The process of passing the water through the beds of such granular materials is known as Filtration. 4/21/2018 13

Filtrationintroduction The purpose of filtration is to remove suspended particles from water by passing the water through a porous medium such as sand. As the water passes through the filter,floc and impurities get stuck in the sand and the clean water goes through. filtered water collects in the clear well where it is disinfected. The 12

Theory of Filtration Forms the most important stage in the purification of water with the following effects Suspended and removed Chemical characteristic of water is altered The number of reduced considerably colloidal impurities are bacteria are Four mechanisms have been found to be part of the filtration process -straining, adsorption, biological action, and absorption 4/21/2018 13

Mechanisms of Filtration Straining passing the water through a filter in which the pores are smaller than the particles to be removed. The floc cannot fit through the gaps between the sand particles, so the floc are captured. The water is able to flow through the sand, leaving the floc particles behind.

Mechanisms of Filtration Adsorption -The most important mechanism of filtration is adsorption. Adsorption is the gathering of gas, liquid,or dissolved solids onto the surface of another material. -Coagulation takes advantage of the mechanism of adsorption when small floc particles are pulled together by van derWaal's forces.In filtration, adsorption involves particles becoming attracted to and "sticking" to the sand particles. Adsorption can remove even very small particles from water.

Mechanisms of Filtration Biological Action The third mechanism of filtration is biological action, which involves any sort of breakdown of the particles in water by biological processes. May involve decomposition of organic particles by algae, plankton, diatoms, and bacteria or it may involve microorganisms eating eachother. Although biological action is an important part of filtration in slow sand filters, in most other filters the water passes through the filter too quickly for much biological action to occur.

Mechanisms of Filtration Absorption absorption, the soaking up of one substance into the body of another substance. In a filter,absorption involves liquids being soaked up into the sand grains After the initial wetting of the sand, absorption is not very important in the filtration process.

THEORY OF FILTRATION Filtration is carries out in three types of filters GRAVITY FILTERS Slow sand filter Rapid sand filter PRESSURE FILTERS 4/21/2018 20

SLOW SAND FILTER Slow sand filters are best suited for the filtration of water for small towns. The sand used for the filtration is specified by the effective size and uniformity coefficient . The effective size, D10, which is the sieve in millimeters that permits 10% sand by weight to pass. The uniformity coefficient is calculated by the ratio of D60 and D10. 4/21/2018 21

CONSTRUCTION OF SLOWSAND FILTER Slow sand filter is made up of a top layer of fine sand of effective size 0.2.to 0.3mm and uniformity coefficient 2 to 3 The thickness of the layer may be 75 to 90 cm. Below the fine sand layer,a layer of coarse sand of such size whose voids do not permit the fine sand to pass through it. The thickness of this layer may be 30cm. The lowermost layer is a graded gravel of size 2 to 45mm and thickness is about 20 to 30cm. The gravel is laid in layers such that the smallest sizes are at the top. The gravel layer is the retains for the coarse sand layer and is laid over the network of open jointed clay pipe or concrete pipes called under drainage. Water collected by the under drainage is passed into the out chamber 4/21/2018 22

4/21/2018 23

OPERATION-SMALL SAND FILTERS The water from sedimentation tanks enters the slow sand filter through a submersible inlet. This water is uniformly spread over a sand bed without causing any disturbances. The water passes through the filter media at an average rate of 2.4 to 3.6 m3/m2/day.This rate of filtration is continued until the difference between the water level on the filter and in the inlet chamber is slightly less than the depth of water above the sand. The difference of water above the sand bed and in the outlet chamber is called the loss of head.

OPERATION-SMALL SAND FILTERS During filtration as the filter media gets clogged due to the impurities, which stay in the pores, the resistance to the passage of water and loss of head also increases. When the loss of head reaches 60cm, filtration is stopped and about 2 to 3 cms from the top of bed is scrapped and replaced with clean sand before putting back into service to the filter. The scrapped sand is washed with the water,dried and stored for return to the filter at the time of the next washing . The filter can run for 6 to 8 weeks before it becomes necessary to replace the sand layer 24

USES SLOWSAND FILTER The slow sand filters are effective in removal of 98 to 99% of bacteria of raw water and completely all suspended impurities and turbidity is reduced Slow sand filters also removes odours,tastes and colours from the water but not pathogenic bacteria which requires disinfection to safeguard against water-borne diseases. The slow sand filters requires large area for their construction and high initial cost for establishment. 4/21/2018 26

RAPID SAND FILTER Rapid sand filter are replacing the slow sand filters because of high rate of Mfiltration ranging from 100 to150m3/ m2/day and small area of filter required 4/21/2018 27

Main Features of Rapid Sand Filter Effective size of sand -0.45 to 0.70mm Uniformity coefficient of sand -1.3 to 1.7 Depth of sand -60 to 75cm Filter gravel - 2 to 50mm size (Increase size towards bottom) Depth of gravel -45cm Depth of water over sand during filtration -1 to 2m Overall depth of filter including 0.5m free board -2.6m Area of single filter unit - 100m2 in two parts of each 50m2 Loss of head -Max 1.8 to 2.0m 27

RAPID SANDFILTER 4/21/2018 29

CONSTRUCTION RAPID SAND FILTER Rapid sand filter consists of the following five parts Enclosure tank A water tight tank is constructed either masony or concrete Under drainage system may be perforated pipe system or pipe and stracher system Base material gravel should free from clay, dust, silt and vegetable matter.Should be durable, hard, round and strong and depth 40cm. Filter media of sand The depth of sand 60 to 75cm Appartenances Air washing of filter and wash water troughs for collection of dirty water after washing of filter compressors useful for 4/21/2018 30

EFFICIENCY OF RAPID SAND FILTER Rapid sand filter bring down the turbidity of water to 1 N.T.U. This filter needs constant and skilled supervision to maintain the filter gauge, expansion gauge and rate of flow controller and periodical backwash 4/21/2018 31

PRESSURE FILTER Pressure filter is type of rapid sand filter in a closed water tight cylinder through which the water passes through the sand pressure. All the operations of the filter is similar to rapid gravity filter, expect that the coagulated water is directly applied to the filter without mixing and flocculation. These filters are used for industrial plants but these are not economical on large scale. Pressure filters may be vertical pressure filter and horizontal pressure filter. The rate of flow is 120 to 300m3/m2/day. bed under 4/21/2018 32

PRESSURE FILTER 4/21/2018 33

ADVANTAGES OF PRESSURE FILTER It is a compact and automatic operation These are ideal for small estates and small water works These filters requires small area for installation Small number of fittings are required in these filters Fitered water comes out under pressure no further pumping is required. No sedimentation and coagulant tanks are required with these units 4/21/2018 34

DISADVATAGES OF PRESSURE FILTER Due to heavy cost on treatment ,they cannot be used for treatment large quantity of water at water works Proper quality control and inspection is not possible because of closed tank The efficiency of removal of bacteria & turbidity is poor. Change of filter media,gravel and repair of drainage system is difficult 4/21/2018 35

DISINFECTIONOF WATER The process of killing the infective bacteria from the water and making it safe to the user is called disinfection. The water which comes out from the filter may contain some disease causing bacteria in addition to the useful bacteria. Before the water is supplied to the public it is utmost necessary to kill all the disease causing bacteria. The chemicals or substances which are usedf4o/21r/20k18illing the bacteria are known as disinfectants 36

REQUIREMENTS OF GOODDISINFECTANTS They should destroy all the harmful pathogens and make it safe for use,. They should not take more time in killing bacteria They should be economical and easily available They should not require high skill for their application After treatment the water should not become toxic and objectionable to the user. The concentration should be determined simply and quickly. 37 4/21/2018

METHODS OFDISINFECTION PHYSICAL METHODS BOILING :Boil the water for 15 to 20 minutes and kills the disease causing bacteria. This process is applicable for individual homes. ULTRA-VIOLET RAYS:Water is allowed to pass about 10cm thickness by ultraviolet rays.This process is very costly and not used at water works.Suitable for institutions. U 4/2L1/T 201R 8ASONIC RAYS:Suitable forinstit 3u 8tions

METHODSOF DISINFECTION CHEMICAL METEOD CHLORINATION :Using chlorine gas or chlorine compounds. BROMINEANDIODINE :It is expensive and leaves taste and odour. POTASSIUM PERMANGANATE: This method is used for disinfection of dug well water,pond water or private source of water. OZONE:Very expensive process, leaves no taste,odour or residual. EXCESS LIME TREATMENT:Needs long detension time for time interval and large lime sludges to be treated. 4/21/2018 39

CHLORINATION Chlorination is the addition of chlorine to kill the bacteria. Chlorination is very widely adopted in all developing countries for treatment of water for public supply. Chlorine is available in gas, liquid or solid form (bleaching powder) 4/21/2018 40

ADVANTAGESOF CHLORINE Chlorine is manufactured easily by electrolytes of common salts (NaCl) It is powerful oxidant and can penetrate the cell wall of organism and its contents. Dosage can be controlled precisely Can be easily detected by simple orthotolidine test Does not form harmful constituents on reaction with organics of inorganics in water L4/e 21a /20v 18es required res idue in waterto ne 41utralis e

PRECAUTIONS IN USING CHLORINE Chlorine gas or liquid is highly corrosive and Lithal to Inhale. Hence it is to be stored carefully in sealed container at a distance. If the water contains phenolic compounds, there is a reaction with chlorine can result in cancer causing substances. 4/21/2018 42

RESIDUAL CHLORINE ANDCHLORINE DEMAND When chlorine is applied in water some of it is consumed in killing the pathogens, some react with organics & inorganic substances and the balance is detected as Residual Chlorine .The difference between the quantity applied per litre and the residual is called Chlorine Demand . Polluted waters exert more chlorine demand. If water is pre-treated by sedimentation and aeration, chlorine demand may be reduced. Normally residual chlorine of 0.2mg/litre is required 4/21/2018 43

Reactions of Chlorine Gas With Water When chlorine gas enters the water,the following reaction occurs Chlorine +Water HypochlorousAcid + HydrochloricAcid Cl2+ H2O HOCl + HCl Hypochlorous acid may further break down, 4d /21e /20p 18ending on pH: 44

Reactions of Chlorine Gas With Water Hypochlorous acid may break down into a hydrogen ion and a hypochlorite ion,or a hydrogen ion and a hypochlorite ion may join together to form hypochlorous acid. The concentration of hypochlorous acid and hypochlorite ions in chlorinated water will depend on the water's pH. higher pH facilitates the formation of more hypochlorite ions and results in less hypochlorous acid in the water. This is an important reaction to understand because hypochlorous acid is the most effective form of free chlorine residual, meaning that it is chlorine available to kill microorganisms in the water. Hypochlorite ions are much less efficient disinfectants. A 45 4/21/2018

DOSAGEOF CHLORINE PLAIN CHLORINATION Plain chlorination is adopted when no treatment other than chlorination is to be given to raw water before supplying to the consumers. The water of springs or deep wells is in most cases pure and can be used after plain chlorination. A rate of 0.8 mg/lit/hour at 15N/cm2 pressure is the normal dosage so as to maintain in a residual chlorine of 0.2 4/2m 46 1/20g 18/lit.

DOSAGE OF CHLORINE SUPER CHLORINATION Super chlorination is defined as administration of a dose considerably in excess of that necessary for the adequate bacterial purification of water. About 10 to 15 mg/lit is applied with a contact time of 10 to 30 minutes under the circumstances such as during epidemic breakout water is to be dechlorinated before supply to the distribution system. 4/21/2018 47

DOSAGE OF CHLORINE BRAKE POINT CHLORINATION When chlorine is applied to water containing organics, micro organisms and ammonia the residual chlorine levels fluctuate with increase in dosage as shown in diagram below 4/21/2018 48

BRAKE POINT CHLORINATION First (between points 1 and 2), the water reacts with reducing compounds in the water (it is absorbed by reducing agents in water such as hydrogen sulfide, nitrates, Iron). These compounds use up the chlorine, producing no chlorine residual. Further increases of chlorine dosage i.e. between points 2 and 3, the chlorine reacts with organics and ammonia naturally found in the water and forms chloramines with ammonia in water and some combined

BRAKE POINT CHLORINATION When more chlorine is added past the breakpoint, the chlorine reacts with water and forms hypochlorous acid in direct proportion to the amount of chlorine added. This process, known as breakpoint chlorination,is the most common form of chlorination,in which enough chlorine is added to the water to bring it past the breakpoint and to create some free chlorine residual. 50 4/21/2018