Understanding Centrifugation: Industrial and Laboratory Applications

Centrifugation is a procedure that utilizes centrifugal force to separate components based on density in mixtures for both industrial and laboratory purposes. This process involves the rotation of particles at high speeds to induce sedimentation. Different types of centrifuges, such as low-speed and high-speed centrifuges, are used depending on the application. Low-speed centrifuges are ideal for quick pelleting of heavy particles, while high-speed centrifuges are used for more advanced biochemical tasks, requiring precise control of speed and temperature.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Centrifugation is a procedure that involves the use of centrifugal force for the sedimentation of mixture with a centrifuge used in industry and in laboratory settings. More dense components of the mixture move away from the axis of the centrifuge while less dense components of the mixture move towards the axis.

A particle whether it is a precipitate a macromolecule or a cell organelle is subjected to a centrifugal force when it is rotated at a high rate of speed. The centrifugal force F is denoted by equation F=m 2 r Where F= intensity of the centrifugal force m= effective mass of the sedimenting particle = angular velocity of rotation r= distance of the migrating particles from the central axis of rotation A more common measurement of F in terms of the earths gravitation force , g, is relative centrifugal force, RCF its defined by RCF = (1.119 x 10-5 (rpm)2 (r) This equation relates RCF to revolutions per minute of the sample . Equation dictates that the RCF on a sample will vary with r, the distance of the sedimenting particles from the axis of rotation . The RCF value is reported as a number times gravity ,g .

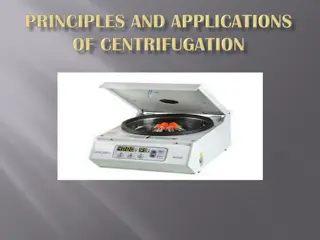

A laboratory tabletop centrifuge. The rotating unit, called the rotor, has fixed holes drilled at an angle (to the vertical). Test tubes are placed in these slots and the motor is spun. As the centrifugal force is in the horizontal plane and the tubes are fixed at an angle, the particles have to travel only a little distance before they hit the wall and drop down to the bottom. These angle rotors are very popular in the lab for routine use.

The basic centrifuge consists of two components one is Electric motor with drive shaft to spin the sample and a Rotor to hold tubes or other containers of the sample. A wide variety of centrifuges are available ranging from a low speed centrifuge used for routine pelleting of relatively heavy particles. There are three types of centrifuges 1.Low speed centrifuges . Its also called as clinical centrifuge. >> 4000 to 5000 rpm with RCF value approx. up to 3000Xg. These instruments usually operate at low temperature with no means of temperature control of the samples. The common centrifuge has a maximum speed in the range of >> used in this instruments. Two types of rotors fixed angle and swinging bucket may be continue .

>> sedimentation of coarse precipitates or red blood cells. Low speed centrifuges are especially useful for the rapid >> pellet at the bottom of the tube. The upper liquid portion, the supernatant, is then separated by decantation. 2. High Speed Centrifuges: >> High speed centrifuges for more sophisticated biochemical applications. Higher speeds and temperature control of the rotor chambers are essential. >> Rotor chambers in most instruments are maintained at or near 40 C. Three types of rotors are available for high speed centrifugation. a. Fixed Angel rotor. b. Swinging bucket rotors c. vertical rotor >> High speed centrifuges are used to sediment >Cell debris after cell homogenization. >Ammonium sulfate precipitates of proteins and cellular organelles such as chloroplasts, mitochondria and nuclei. The sample is centrifuged until the particles are packed into a

3. >> ultracentrifuges because of the high speeds attainable intense heat is generated in the rotor so the spin chamber must be refrigerated and placed under high vacuum to reduce friction. >> it is a high speed centrifuge that has fixed head rotors. It is mainly used in separation of lipoproteins. Since the separation is long process there is generation of heat and thus are provided with internal cooling system. >> Ultracentrifuges can be used both for preparative work as well as for analytical. Preparative models its primarily used for separations and purification of samples for further analysis and analytical models which are designed for performing physical measurements on the sample during sedimentation. Ultracentrifuge s: The most sophisticated of the centrifuges are the

Types of Centrifuges & applications Types of centrifuge Characteristic Low Speed High Speed Ultracentrifuge Range of Speed (rpm) 1-6000 1000-25,000 20-80,000 Maximum RCF (g) 6000 50,000 6,00,000 Refrigeration some Yes Yes Applications Pelleting of cells Yes Yes Yes Pelleting of nuclei Yes Yes Yes Pelleting of organelles No Yes Yes Pelleting of ribosomes No No Yes Pelleting of Macromolecules No No Yes

Glass centrifuge tubes can be used with most solvents, but tend to be more expensive. They can be cleaned like other laboratory glassware, and can be sterilized by autoclaving. Plastic centrifuge tubes, especially micro-centrifuge tubes tend to be less expensive. Water is preferred when plastic centrifuge tubes are used. They are more difficult to clean thoroughly, and are usually inexpensive enough to be considered disposable

Centrifuge tubes http://upload.wikimedia.org/wikipedia/en/thumb/7/72/Screw_Top_Microcentrifuge_Tubes.jpg/220px-Screw_Top_Microcentrifuge_Tubes.jpg http://upload.wikimedia.org/wikipedia/commons/thumb/6/6d/Eppendorf_tubes.jpg/220px-Eppendorf_tubes.jpg Four screw-top micro- centrifuge tubes. Three microcentrifuge tubes: 2 mL, 1.5 mL and 200 L .

Preparative Techniques Centrifuges in undergraduate biochemistry laboratories are used most often for preparative scale separation . This technique is quite straightforward consisting of placing the sample in a tube or similar container inserting the tube in the rotor and spinning the sample for a fixed period. The sample is removed and the two phases ,pellet and supernatant may be separated by careful decantation further characterization or analysis is usually carried out on the individual phases . This technique called as velocity sedimentation centrifugation, separates particles ranging in size from coarse precipitates to cellular organelles .

In this process a tissue is first Homogenised to break the cell membranes and mix up the cell contents. The homogenate is then subjected to repeated centrifugations. Each time removing the pellet and increasing the centrifugal Finally purification may be done through equilibrium sedimentation and the desired layer extracted for further analysis . Separation is based on size and density, with larger and denser particles pelleting at lower centrifugal force. technique is similar to preparative differential centrifugation but the goal of an experiment is to measure the sedimentation coefficient of the particle force. Although the

A procedure for separating particles such as viruses or ribosome or molecules such as DNA in which the sample is placed on a preformed gradient such as sucrose or cesium chloride. Upon centrifugation either by rate zonal or equilibrium procedures, the macromolecules are 'banded' in the gradient and can be collected as a pure fraction . Density gradient centrifugation permits the separation of multicomponent mixtures of macromolecules and the measurement of sedimentation coefficient . Two methods are used zonal centrifugation in which the simple is centrifuged in a preformed gradient and isopycnic centrifugation in which a self generating gradients forms during centrifugation.

Denisty gradient centrifugation It allows separation of many components in a mixture by creating density gradient during centrifugation There are two forms of density gradient centrifugation: Rate zonal and Isopycnic

Rate Zonal Centrifugation (also termed sedimentation velocity, zone centrifugation) In rate zonal centrifugation, the sample is applied in a thin zone at the top of the centrifuge tube on a density gradient. Under centrifugal force, the particles will begin sedimenting through the gradient in separate zones according to their size shape and density. The run must be terminated before any of the separated particles reach the bottom of the tube. Swing bucket rotor

Isopycnic centrifugation (also termed sedimentation equilibrium centrifugation) During the centrifugation, the CsCl generates a gradient ( self-generating gradient ), and the molecules move to the position in the gradient where their density is the same as the gradient material. Isopycnic means same density, so the molecules move to their isopycnic position. Gradients Fixed angle or swing bucket rotor Sucrose CsCl2 Glycerol Dextran