Weekly Planning Meeting Summary - Tasks and Updates

Planning meeting held on 3/12/20 covered various infrastructure tasks like track repairs, detector rack layout, and summer work plans. Additionally, progress updates were shared regarding inner HCAL mock-up designs, iHCAL cables termination, and electronics assignments. The focus was on coordinating repairs, layout enhancements, and future projects involving cooling systems and equipment evaluations.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

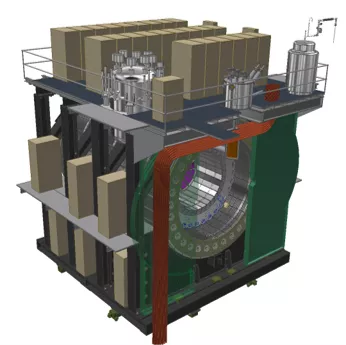

sPHENIX Planning Weekly Planning Meeting 3/12/20

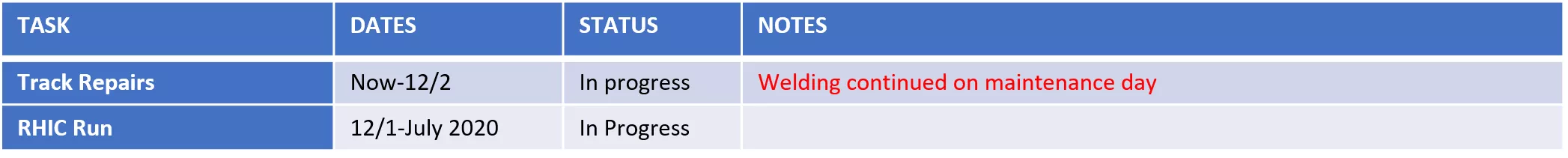

Infrastructure/1008 TASK DATES STATUS NOTES Track Repairs Now-12/2 In progress Welding continued on maintenance day RHIC Run 12/1-July 2020 In Progress

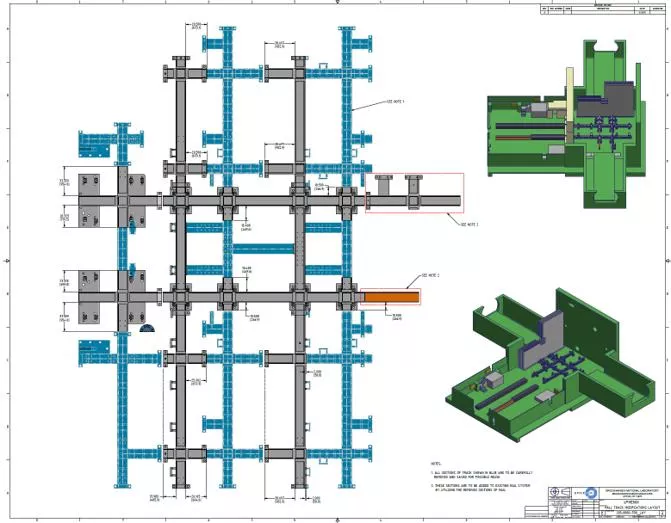

Detector Rack Layout - Upper platform rack locations per dwg # 205-0700-100 & access hole proposal West Side East Side Rack access hole: 10 x 17 = 170 in2 Rack envelope 3 March 11th, 2020 Platform Layouts Review

Infrastructure Summer Work To Do List: Identification of existing infrastructure and provide requirements to integrate cooling system for PRR computer / electronic racks. David Chan & B.S. will submit a conceptual design in the next few weeks. Brian - Is there any work to be done during the summer for PRR computer / electronic racks (cooling)? Duct work? Evaluate equipment on UPS. UPS testing / Battery replacement PASS beam imminent enclosures conduits need to be re-routed. (B.S) Concrete Pouring track modifications. (B.S.) Rack interlock prototype (J.V) A tech is needed to help the students with prototype installation Flood lights in assembly hall need replacement, new LED 400w Preliminary Sketch Not to scale sPHENIX Summer Work 4

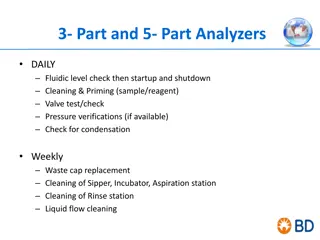

Inner HCAL Mock Up Task ENDPLATES Converge on Design New endplate design Review/change/sign off on new endplates Fabricate new endplates Receive/install new endplates Design Cover plates for endplate opening ELECTRONICS Assigned to Status Notes RR/EM/SB RR COMPLETE COMPLETE COMPLETE C. Biggs COMPLETE COMPLETE COMPLETE RR All boards have been acquired Pre amp boards have been installed Identify/collect ihcal electronics FT In Progress Make Cables Pre amp Power Cables (48) Run Cables/install sipm s/Install pre amp boards Install thermal testing cables Run Test of electronics Determine lengths for: Signal Cables Fiber Bundles SiPM Daughter Board Cables MECHANICAL Design Skins Purchase Material for skins Fabricate Skins Design Tile Holders (3D part) Design Pre Amp Holder (3D part) Print 3D parts AB In Progress F. Toldo/Daniel Lay out "signal" lengths JH/SB FT RR complete complete complete Complete Complete In Progress Tech RR RR RR

iHCAL Cables Who is doing the work Part 1 Sector In House Need to be completed Status Notes Currently terminating P1 connector on 1st fiber bundle 48 Preamp Power Cables 48 0 AB Signal Cables 24 0 24 48 8 2 240 Thermistor Cable Fiber Bundles Test Pulse Jumpers SiPM w/ pigtails 48 8 2 240 0 0 0 0 Removing boards from oHCAL sector 48 Preamp boards Ribbon Cable (LED Driver) Salt/Pepper Shakers 48 2 10 0 2 10 0 0 COMPLETE COMPLETE

oHCAL Cables Preproduction amount House completed In Need to be Who is doing the work Part 1 Sector Status Notes 1 set made in house; Becker delivered other 5 sets Meritec Cable: The cable that is purchased from MERITC and used to produce cable assemblies Cable Assembly: The cable assembly that is installed and services 2 preamps. Assembled from 1/2 of a Meritec cable. Cable Set: 24 cables assemblies required to instrument an HCal module. Technician will need to place connectors on production cables Preamp Power Cables 48 288 288 0 Complete Becker (Vendor) Signal Cables 24 144 144 0 Complete Thermistor Cable Fiber Bundles Test Pulse Jumpers 48 10 2 288 60 12 288 60 12 0 0 0 Complete Complete Complete Frank Toldo Outside Contractor All Parts in house SiPM w/ pigtails Preamp boards Ribbon Cable (LED Driver) Salt/Pepper Shakers 240 48 2 10 1440 288 12 60 1440 288 62 60 0 0 Complete Complete Complete Complete -50 0 All Parts in House

EMCAL Block prep for Sec's 2 and 3 going well. Continuing to pre-manufacture as many sector parts as possible. Waiting on the following: North Sawteeth (SBU) 1-2 weeks out SiPM Daughter cards (May ?) SiPM Covers 2-3 weeks out (buyer screwed up) SiPM Cooling manifolds US estimate was HIGH Rob setting up new chillers for test tent. New blocks arrived Sec 1 w/ cooling test fit Putting in the man hours Sec 0 testing almost complete

Activity Duration Dates Resources Beam Pipe removal 1 tech/Vacuum group Clean out IR floor area 2 techs Track removal from IR 2-3 techs Track work AH 1-2 techs Rack moving/plumbing 2 techs/electrician/plumber Cable removal-rack room to control room 1 tech Rack building 1-2 techs Ongoing cable termination 1 tech Outer Hcal support Ongoing Inner Hcal support Emcal Support Ongoing West wall platform installed June NO TECH NEEDED West wall dog house June NO TECH NEEDED IR tracks modified/fabricated Ongoing NO TECH NEEDED Clear out IR 2 techs Bus work 1008B and IR July-August Cad tech/1 tech Cable tray work 1008B and IR September NO TECH NEEDED UPS System tests Rack Interlock Prototype Access Control cables rerouted Concrete Pouring track mods

sPHENIX Spring/Summer 2020 Planner ACTIVITY MAY JUNE JULY AUGUST SEPTEMBER OCTOBER NOVEMBER DECEMBER On Going sPHENIX Support Emcal Factory Hcal Factory Inner HCAL Support 1008 Assembly Hall Work Remove Shield Wall AH Tracks Upgrade Install Shield Wall 1008 IR Work Clean out IR floor area Remove IR Tracks West Wall Cryo Deck Install Cryo West Wall Dog House Bus Work 1008B to IR Beam pipe removal IR Tracks modified/fabricated PASS cable rerouting Concrete Pour 1008 Other Work Cable Tray 1008B to IR Rack Moving/Plumbing Cable Removal- rack room to control room Rack Building UPS Systems Test Rack interlock prototype Additional Lighting in AH/IR

WBS 2.5.3-2.5.12 sPHENIX Installation Sequential Build Steps Concurrent Work Streams CY 2021 2022 2023 Cradle-Base oHCAL Sector 1-13 Magnet Install Inner Support Rings Start: March 21 WBS 2.5.2 Work Wiring, Piping, Cabinets Other AH and IR work QC and Safety Checks oHCAL Sector 14-32 Key Predecessors AH/IR Rail Mods Cradle-Base Ready iHCAL EMCAL Open Shield Wall Carriage and pole tips ` Move sPHENIX to IR Magnet connect, map TPC INTT support structure WBS 2.5.2 Work Infrastructure connections to Cradle/Carriage Magnet work Wiring, Piping, Cabinets Other AH and IR work QC and Safety Checks Beam pipe insert & bake ORR INTT device 01-Nov-22 MVTX device Start RHIC 30-Jan-23 Final beam pipe MBD device FY21 RHIC Run 1/4/21 to 5/13/21 FY22 RHIC Run 9/1/21 to 12/30/21 ORR Prep and ORR