Volvo EC15B XR (EC15BXR) Compact Excavator Service Repair Manual Instant Download

Please open the website below to get the complete manualnn// n

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

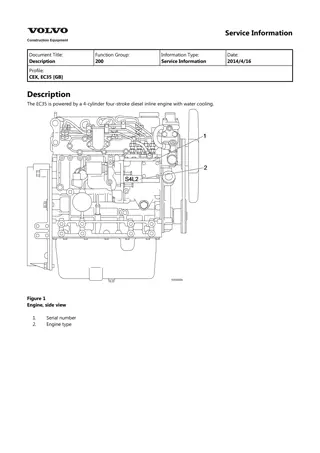

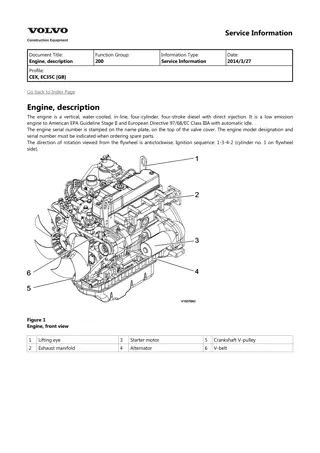

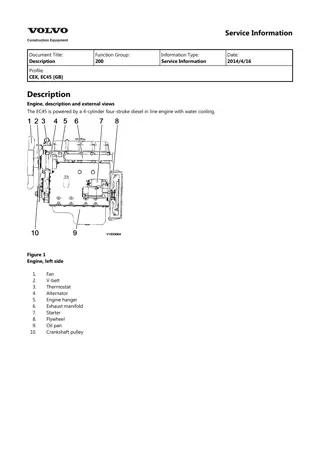

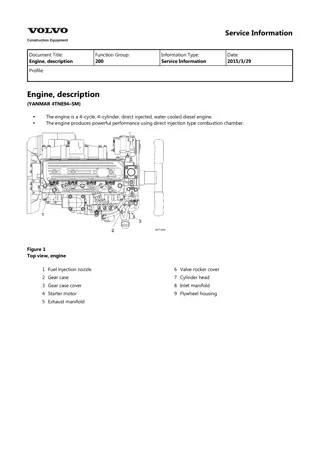

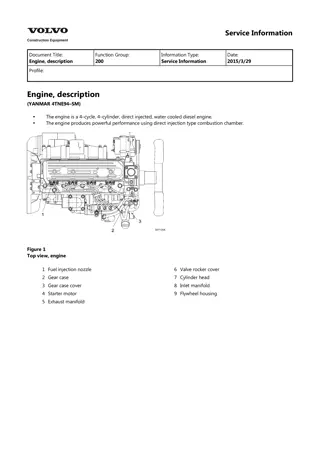

Service Information Document Title: Description Function Group: 200 Information Type: Service Information Date: 2014/6/22 Profile: Description The EC15/EC20B is powered by a water-cooled 3-cylinder four-stroke inline diesel engine with water cooling.

Service Information Document Title: Engine trouble shooting Function Group: 200 Information Type: Service Information Date: 2014/6/22 Profile: Engine trouble shooting Engine faults must be detected and rectified as quickly as possible in order to avoid more expensive repairs. The following table summarizes the most important faults and their rectification. Problem/fault Engine does not start Possible cause of fault Starter switch defective Starter power too low Fault remedy Tighten connections. Replace the switch. If the starter is OK, check condition of battery and electric connections. Bleed the system. Replace the air filter. Check viscosity and fill in correct oil. Check the function of the preheater plug. Check and adjust the injection valves Replace defective valves. Adjust the injection timing. Check the valve clearance. Check condition of cylinder head gasket, valves and piston rings. Fill in fuel. Bleed the fuel system. Clean or replace the fuel filter. Check connection of fuel pump or replace fuel pump. Clear or replace the exhaust system. Replace the pump. Clean or replace the fuel filter. Bleed the fuel system. Clean the air filter. Check the intake air. Check and adjust the injection valves Replace defective valves. Check elements (water pump, radiator, thermostat, cylinder head gasket, coolant hoses). Check presence, tension and cleanliness of V-belt. Check elements (oil filter, oil pump, suction filter) and replace defective parts. Adjust the injection timing. Check the valve clearance. Fill in oil. Check whether the oil in the engine meets the operating conditions. Adjust the governor. Correct the coolant level. Check whether the coolant meets the operating conditions. Clean or replace the air filter. Check quality of fuel and suitability for climatic Air in fuel system Air filter dirty Wrong oil viscosity Engine too cold Injection valves defective Incorrect injection timing Compression pressure too low Engine shuts down automatically Fuel tank empty Air in fuel system Fuel filter dirty Fuel pump defective Exhaust system clogged Fuel pump defective Fuel filter dirty Erratic running of engine Air filter dirty Injection valves defective Engine overheating Cooling system elements defective Fan not running Lubrication system elements defective Incorrect injection timing Oil level too low Governor incorrectly adjusted Coolant level not correct Engine black smoke develops Air cleaner soiled Poor fuel quality

conditions. Valve clearance and injection timing not correct Adjust valve clearance and injection timing. Compression pressure not O.K. Check condition of cylinder head gasket, valves and piston rings. Check and adjust the injection valves Check injection pump, replace if necessary. Adjust the control cable. Fill in oil as required for the operating conditions. Check quality of fuel and suitability for climatic conditions. Adjust valve clearance and injection timing. Injection pressure not O.K. Injection pump defective Engine control cable incorrectly adjusted Poor engine oil quality Poor fuel quality Irregular idle speed Valve clearance and injection timing not correct Opening pressure of injection valves not correct Compression pressure not O.K. Check opening pressure and injection valves. Check condition of cylinder head gasket, valves and piston rings. Check injection pump, replace if necessary. Check quality of fuel and suitability for climatic conditions. Clean or replace the air filter. Adjust the injection timing. Check the engine shut-down solenoid. Adjust the injection valves. Check condition of cylinder head gasket, valves and piston rings. Replace the injection pump. Check oil level and oil quality and fill in specified oil. Check and replace the oil pressure switch. Tighten the V-belt and replace a defective V-belt. Check and replace the generator. Replace the battery. Check correct connection of cables. Check regulator, replace if necessary. Tighten connections. Replace the switch. Check the engine solenoid, replace if necessary. Injection pump defective Poor fuel quality Unusual noise engine Air cleaner soiled Incorrect injection timing Engine shut-down solenoid not O.K. Injection pressure not O.K. Compression pressure not O.K. Injection pump defective Oil level and oil quality not correct Oil low pressure too Oil pressure switch defective Fan V-belt too loose Generator defective Battery defective Wiring not O.K. Regulator defective Starter switch defective Engine shut-down solenoid not O.K. Battery condition too low charge Engine cannot be shut down

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

Service Information Document Title: Installing the engine Function Group: 200 Information Type: Service Information Date: 2014/6/22 Profile: Installing the engine Op nbr 2101 Lifting sling 1 m Shackle 3/8"" Figure 1 1. Attach the lifting tackle to the engine. Weight approx. 125 kg. 2. Place the engine into the engine carrier. 3. Cover the threads of screws (1) with Loctite, turn them into the rear engine suspension and tighten with 105 Nm. Figure 2 4. Cover the threads of screws (5) with Loctite, turn them into the front engine suspension and tighten with 105 Nm. 5. Assemble the exhaust system with a new seal to the exhaust manifold. 6. Turn in screws (1 and 2) and tighten with 30 5 Nm. 7. Fasten the exhaust bracket to the engine carrier and tighten the screws (4 and arrow) with 60 10 Nm.

Figure 3 8. Turn in screw (1) on both tie rods and tighten with 30 5 Nm. Figure 4 9. Attach the radiator grid, turn in screws (1) and tighten with 30 5 Nm. 10. Assemble top and bottom coolant hose with new hose clamps. 11. Close the drain screw and fill in coolant. Filling capacity: approx. 5 l 12. Insert the engine with radiator and engine carrier and connect the following components: Generator Starter 13. Push the engine forward and lower it. Figure 5 14. Turn the fastening screws (1) into the engine carrier (2) and tighten with 105 Nm. 15. Remove the lifting tackle to the engine.

Figure 6 16. Install oil cooler (4) and tighten screw (1) with 12 2 Nm. 17. Insert rod (3) and secure with clamp (2). Figure 7 18. Install hydraulic pump (1), cover the screws with Loctite, turn them in and tighten with 105 Nm. Figure 8 19. Assemble fuel tank, filter and air filter and tighten the screws (3) with 30 5 Nm. 20. Connect fuel line (2). 21. Fasten throttle control (1) on injection pump and adjust throttle cable.

Figure 9 22. Connect the breather line (1) to the hydraulic oil tank. 23. Install the engine wiring loom and connect the following components: Air filter contamination indicator Fuel sensor Glow plug Shut-off solenoid Plug for hand lamp Temperature switch Ground strap on engine and engine carrier Fasten the cables with cable straps. 24. Assemble the fastening clamps for engine cable set. Figure 10 25. Fasten the air intake hose (2) with a new hose clamp (1) to the air intake pipe. Figure 11 26. Assemble hood with engine hood. 27. Assemble the suction hose with a new hose clamp (1).

28. Bleed the fuel system. 29. Connect the ground cable to the battery. 30. Lift the counterweight up and fasten with the screws. 31. Check engine oil level, top up if necessary 32. Start the engine and make sure that there are no leaks.

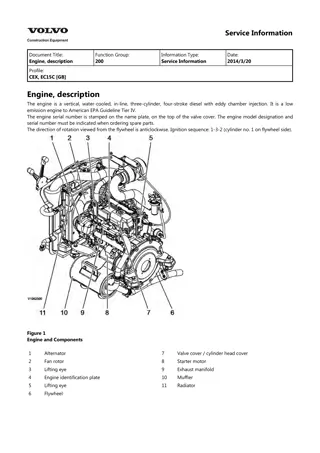

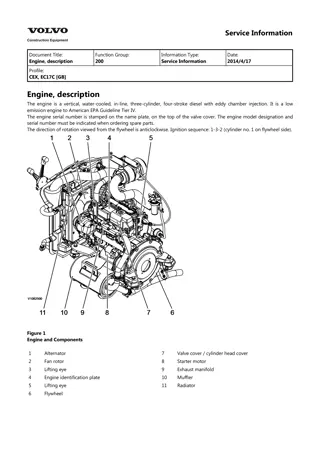

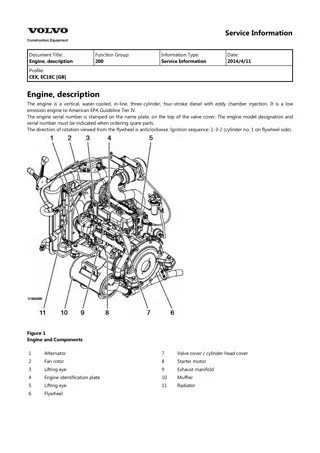

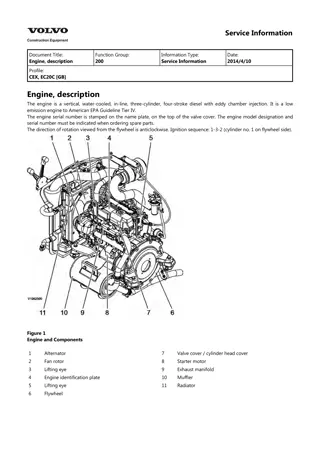

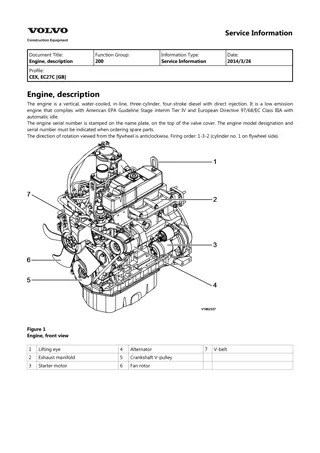

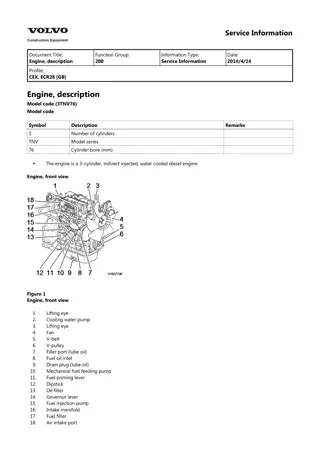

Service Information Document Title: Operator side Function Group: 200 Information Type: Service Information Date: 2014/6/22 Profile: Operator side Figure 1 Engine, side view 1. 2. 3. 4. 5. 6. 7. 8. 9. Oil filler neck Injection pump Water pump Oil filler neck Crankshaft pulley Oil filter Oil drain plug Oil dipstick Flywheel Coolant drain plug Intake manifold Injection nozzle 10. 11. 12.

Service Information Document Title: Performance characteristics (measuring values for one hour with fan) Function Group: 200 Information Type: Service Information Date: 2014/6/22 Profile: Performance characteristics (measuring values for one hour with fan) Engine performance diagram Figure 1

Service Information Document Title: Removing the engine Function Group: 200 Information Type: Service Information Date: 2014/6/22 Profile: Removing the engine Op nbr 2101 Lifting sling 1 m Shackle 3/8"" WARNING Disconnect and connect the battery only with the ignition switched off. Disconnect the minus pole (green fastening) first. During assembly connect the plus pole (red cable) first. Figure 1 1. Disconnect the ground cable from the battery. 2. Unscrew both screws (arrows) on both sides of the counterweight. 3. Pull safety lever (1) and move the counterweight to bottom position. Figure 2

4. Unscrew the front socket head cap screws (1) for the hood (2). Figure 3 5. Loosen hose clamp (1) and place the stop hose (2) to the side. Figure 4 6. Unscrew both rear socket head cap screws (1) and take off hood with engine hood. Figure 5 7. Loosen hose clamp (1) and pull air intake hose (2) off the air intake pipe. 8. Close openings on the engine with adhesive tape. 9. Disconnect all necessary electrical cables and terminals from the following components: Air filter contamination indicator Fuel sensor Glow plug Engine shut-down solenoid Plug for hand lamp Temperature switch Ground strap on engine and engine carrier 10. Remove the fastening clamps for engine cable set.

Figure 6 11. Remove the breather line (1) from the hydraulic oil tank. Figure 7 12. Unhook throttle cable (1) from the injection pump. 13. Disconnect fuel supply line (2). 14. Unscrew all screws (3) from the fuel tank. 15. Remove fuel tank, filter and air filter as one unit. Figure 8 16. Disassemble hydraulic pump (1) from engine, lay to the side and fasten it safely.

Figure 9 17. Unscrew fastening screws (1) for engine carrier (2). Figure 10 18. Attach lifting tackle (1) to the engine. 19. Lift the engine up and pull it out towards the rear. 20. Disconnect all necessary electrical cables from the following components: Starter Generator Figure 11 21. Unscrew screw (1). 22. Unhook calmp (2) and push out rod (3). 23. Lay oil cooler (4) to the side and fasten it. 24. Lift out engine with radiator and engine carrier.

WARNING When opening the lid of the compensation tank (radiator cap) there is a risk of scalding because of the overpressure in the cooling system. Catch running out coolant and dispose of environmentally. 25. Unscrew the drain plug, open the radiator cap and drain of all coolant. Filling quantity approx. 5 litres. 26. Disconnect the water hose from the compensation container on the radiator. 27. Remove top and bottom coolant hose Figure 12 28. Unscrew both screws (1) and take off the radiator grid (2). Figure 13 29. Unscrew screw (1) from both tie rods (2). Figure 14 30. Unscrew screw (1) from support (2). 31. Remove screws (3) from the exhaust flange. 32. Unscrew screws (4 and arrow) and take off the complete exhaust system.

33. Unscrew both screws (5) of the front engine suspension. Figure 15 34. Unscrew both screws (1) of the rear engine suspension. 35. Take the engine out of the engine carrier. Weight: approx. 125 kg

Service Information Document Title: Specification, engine Function Group: 200 Information Type: Service Information Date: 2014/6/22 Profile: Specification, engine Type Engine Working principle Firing sequence (injection sequence) Compression ratio Type of combustion chamber Number of cylinders Bore x stroke, mm Displacement, cm3 Compression pressure Max. permissible pressure deviation between cylinders Idle speed Full speed Installed net power (ISO 9249) Maximum torque Cooling Air filter EC15B EC20B L3E2-64ESA Four stroke inline diesel engine, water cooled 1 - 3 - 2 23:1 Swirl chamber 3 76 x 70 952 32 bar 3 bar 1050 + 40 rpm 2300 + 20 rpm 1.1 kW at 2150 rpm 50 kW at 1800 rpm Centrifugal water pump with temperature control Dry

Service Information Document Title: Specification, capacities Function Group: 200 Information Type: Service Information Date: 2014/6/22 filling Profile: Specification, filling capacities Engine, oil change incl. filter 3.6 l

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

Service Information Document Title: Specification, weight Function Group: 200 Information Type: Service Information Date: 2014/6/22 Profile: Specification, weight Engine, standard 125 kg

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com