Tractor Maintenance Checklist & Materials Used in Manufacturing

This comprehensive guide outlines essential maintenance tasks for tractors, covering cooling system, battery, tires, fuel system, and more. Additionally, it discusses materials used in manufacturing products such as metals, woods, and plastics. The guide emphasizes regular checks to ensure optimal performance and longevity of tractors and implements.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

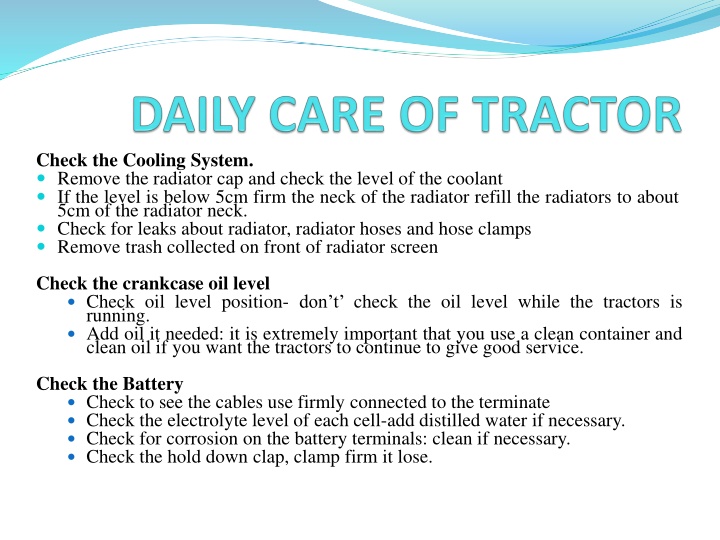

Check the Cooling System. Remove the radiator cap and check the level of the coolant If the level is below 5cm firm the neck of the radiator refill the radiators to about 5cm of the radiator neck. Check for leaks about radiator, radiator hoses and hose clamps Remove trash collected on front of radiator screen Check the crankcase oil level Check oil level position- don t check the oil level while the tractors is running. Add oil it needed: it is extremely important that you use a clean container and clean oil if you want the tractors to continue to give good service. Check the Battery Check to see the cables use firmly connected to the terminate Check the electrolyte level of each cell-add distilled water if necessary. Check for corrosion on the battery terminals: clean if necessary. Check the hold down clap, clamp firm it lose.

Check the Tyres: Check the tyres for the right pressure recommended by the manufacturers. Check side walls for cuts or breaks Check treads for nails, stones etc. Check fuel level: Add if necessary Check the fuel system Check hose for leaks For diesel fuel system, check for drain cock on: Bottom of fuel tank Bottom of first fitter Top of sediment bowl. Open and drain about 1 pint of fuel to make certain that water and sediment are removed. Lubricant with grease is not daily job but carry it out as regularly as recommended by the manufacturer. Make sure your cloths are free from tears bulging pockets, flayed edges and heavy cutts. Also wear shoes with heels and tight soles. Check miscellaneous items: water for loose nuts bents brachets that need straightening worm parts that need replacing, loose or worn fan belts loose wheel etc. starting a Diesel type engine: 1. 2. 3. 4. 5. 6. 7. 8. 9.

IMPLEMENT MAINTANANCE The tractor driver is responsible for opening implements or machine which he used with or tractor. All implements or machines titled with grease implies regaire grease twice daily or every 5hrs. The oil level in gear boxes of P.T.O or pulley drives replacement or machine should be checked twice daily. All nuts and bolts should be checks for tightens twice daily. All tyre pressure should be checked daily Adjustment of rubber belts or P.T.O drivers implements should be checked daily. The hoses and nozzles of sprayer must be checked frequently when in use for leaks or blockages. The coupling and adjustment of 3 pt linkages 1. Leveling aim 2. Lift aim 3. Check chain 4. Draft control level: soil engaging implement 5. Position control level: for min engagement implement.

Materials used in manufacturing products Materials used in manufacturing products METALS Ferrous metals Non-ferrous metal WOOD (TIMBER) Soft woods Hard woods PLASTICS Thermosetting plastics Thermo Metals Ferrous metals contain iron as the main constituent. Such metals are pig iron, cast iron, wrought iron, steel e.t.c. -Pig iron (crude form of iron) is used as a raw material for the production of various other ferrous metals (such as cast iron, wrought iron and steel). It is obtained by melting iron ores in a blast furnace at a temperature of 1500C. Non ferrous metals contain metal other than iron as the main constituent e. g aluminium, copper, zinc, lead, brass, tin