Checklist for Inspecting Pallet Racks

Inspecting pallet racks is crucial for ensuring workplace safety and efficiency in warehouses or storage facilities. Hereu2019s a checklist you can use for inspecting pallet racks:nn//seerackinginspections.medium.com/checklist-for-inspecting-pallet-racks-a1b96b4acdad

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

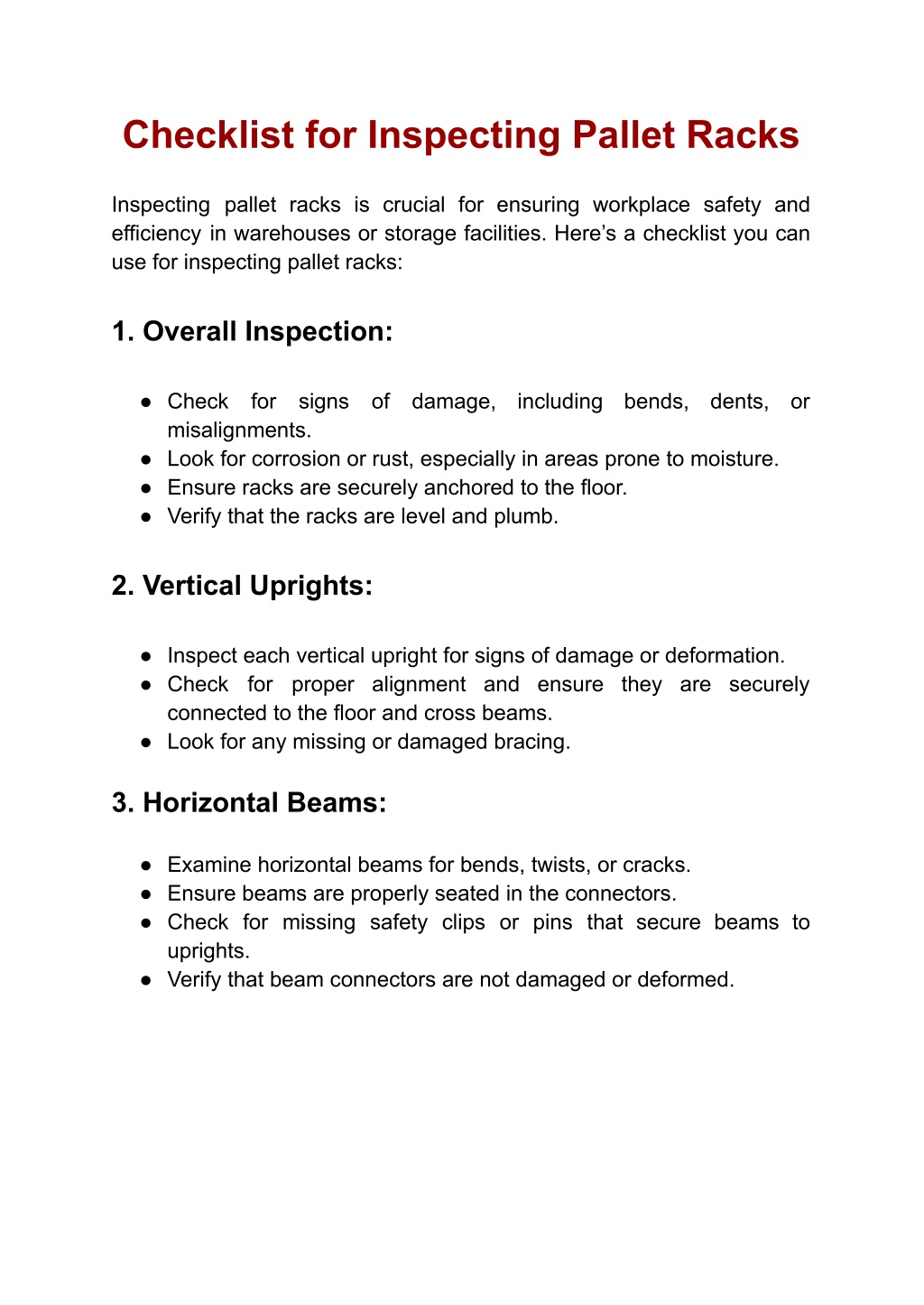

Checklist for Inspecting Pallet Racks Inspecting pallet racks is crucial for ensuring workplace safety and efficiency in warehouses or storage facilities. Here s a checklist you can use for inspecting pallet racks: 1. Overall Inspection: Check misalignments. Look for corrosion or rust, especially in areas prone to moisture. Ensure racks are securely anchored to the floor. Verify that the racks are level and plumb. for signs of damage, including bends, dents, or 2. Vertical Uprights: Inspect each vertical upright for signs of damage or deformation. Check for proper alignment and ensure they are securely connected to the floor and cross beams. Look for any missing or damaged bracing. 3. Horizontal Beams: Examine horizontal beams for bends, twists, or cracks. Ensure beams are properly seated in the connectors. Check for missing safety clips or pins that secure beams to uprights. Verify that beam connectors are not damaged or deformed.

4. Wire Decking for Pallet Supports: Inspect wire decking or pallet supports for damage, corrosion, or missing parts. Ensure they are properly seated and secured on the beams. Check for any sharp edges or protrusions that could damage stored items. 5. Safety Measures: Confirm that safety guards, such as backstops or column protectors, are in place and intact. Ensure aisle markings and load capacity signs are clearly visible. Check for adequate lighting in the rack area. 6. Load Levels: Assess the load distribution on each level of the rack. Ensure loads are evenly distributed and not exceeding weight limits. Check for any signs of overloading, such as sagging beams or uprights. 7. Clearances and Accessibility: Ensure there is sufficient clearance between racks and other structures, such as walls or overhead obstructions. Confirm that aisles are clear and accessible for forklifts or other equipment.

8. Documentation and Maintenance: Review inspection records and maintenance schedules. Check for any outstanding repair or maintenance issues. Verify that any previous identified issues have been addressed. 9. Emergency Procedures: Ensure employees are familiar with emergency procedures in case of a rack failure or collapse. Review evacuation routes and assembly points. 10. Special Considerations: If seismic activity is a concern, check for seismic bracing and ensure it is properly installed. Consider environmental factors such as temperature and humidity, which can affect the integrity of the racks. Regular inspections of pallet racks are essential for maintaining a safe working environment and preventing accidents. It s important to address any issues promptly and to involve qualified personnel for repairs or modifications as needed. Original Blog - https://seerackinginspections.medium.com/checklist-for-inspecting-pallet -racks-a1b96b4acdad